Heat curable resin composition, and mounting method and reparing process for circuit board using the heat curable composition

A resin composition, a technology for circuit substrates, which are applied in the bonding method of adhesive heating, maintenance/correction of printed circuits, assembling printed circuits with electrical components, etc. The problem of increase, unit price, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

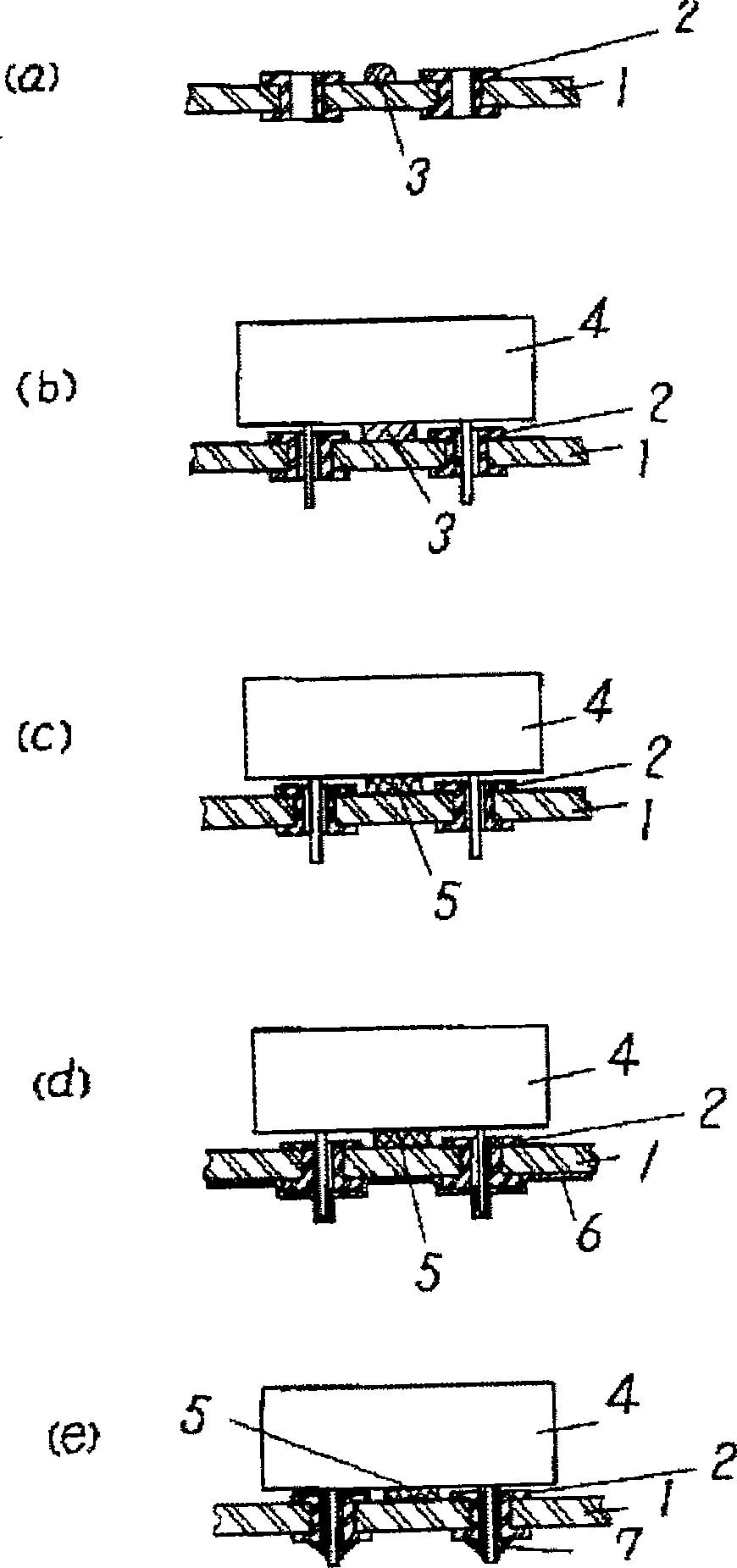

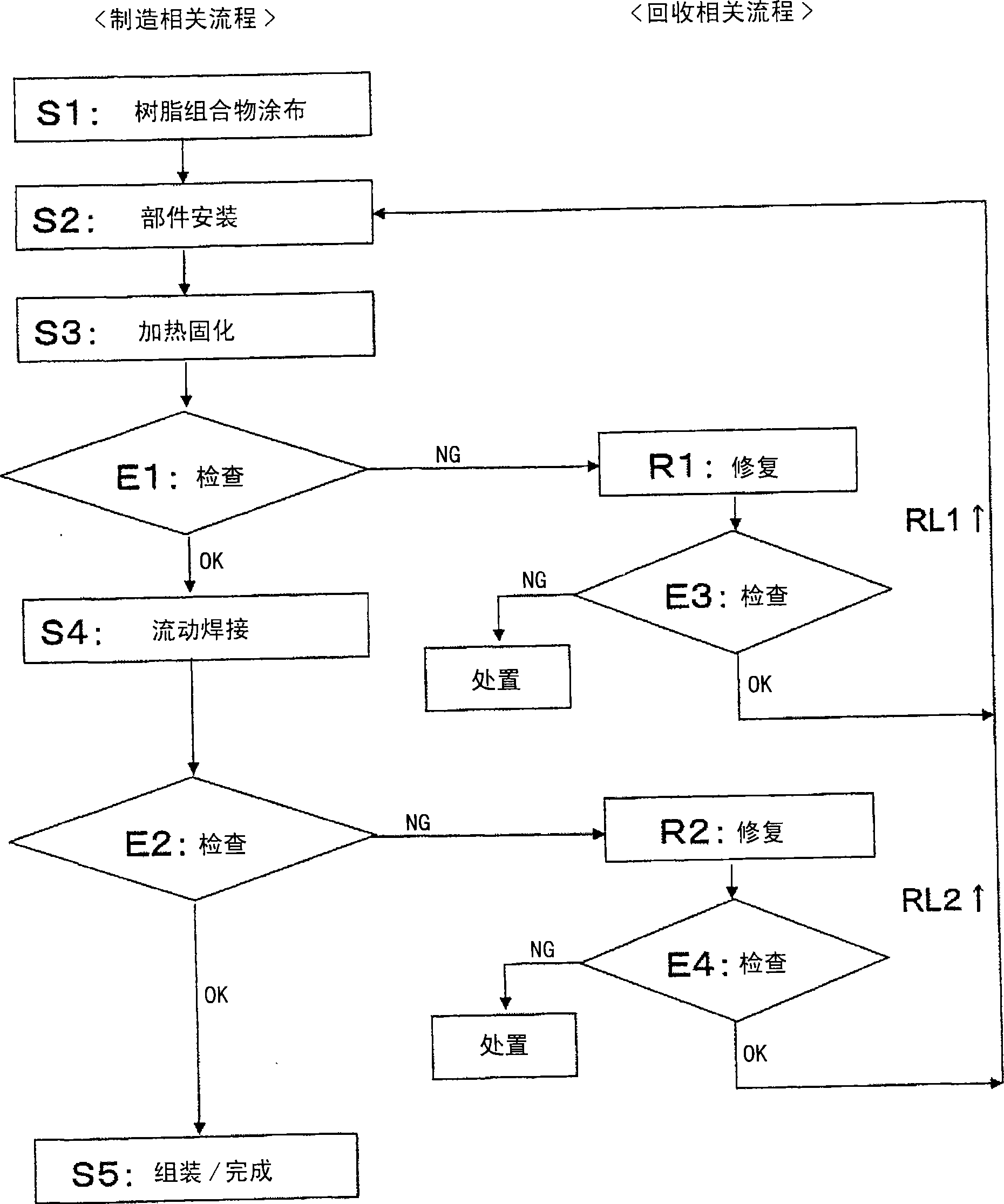

Method used

Image

Examples

example 1

[0139] The following operations are performed on the circuit board in the temporary fixing stage, and recycling is performed without damaging both the circuit board and the miniature transistors. Place the circuit board on a table adjacent to a hot air heater capable of blowing hot air at 80°C, and use a thermocouple to measure the temperature (T1) of the circuit board surface below the miniature transistor and the temperature (T2) of the resin composition. , blowing hot air. The resin composition is a composition in which a bisphenol A type epoxy resin is blended with a mercaptan curing agent, an organic-inorganic composite insulating filler, and an imidazole curing accelerator.

[0140] The glass transition temperature (Tg) of the resin composition used for this temporary fixing was measured in advance using a dynamic viscoelasticity measuring device (manufactured by Seiko Instruments Co., Ltd.), and it was about 42°C.

[0141] Therefore, hot air is blown until T2 becomes 4...

example 2

[0145] Assuming that there is an abnormality in the electronic component, it should be recycled without damaging the circuit board, and the circuit board in the temporary fixing stage is processed as follows. The resin composition had the same composition as in Example 1, and its glass transition temperature (Tg) was about 42°C. Using a thermocouple in the same manner as in Example 1, the temperature ( T1 ) of the circuit board surface below the mini-transistor and the temperature ( T2 ) of the resin composition were measured.

[0146] Press the soldering iron on the mini transistor fixed on the circuit board with the resin composition, bring T2 to 50°C, and pick the mini transistor with tweezers. T1 at this time was 75°C. As in Example 1, the resin composition was easily broken, and the miniature transistors could be easily separated from the circuit board.

[0147] Thereafter, the mini-transistor was transferred to the electronic component recovery process, but it was not ...

example 3

[0149] In the case of the same circuit board as in Example 1, the circuit board taken out from the flow soldering step (S4) was processed through the repairing step (R2). The following operations are performed on the circuit board of the soldering process, and recycling is performed without damaging both the circuit board and the miniature transistors.

[0150] Surround the reed of the mini-transistor with a copper mesh, apply a soldering iron to the reed, melt most of the attached solder, suck it onto the copper mesh and remove it. Thereafter, the circuit board was placed on a table adjacent to a hot air heater capable of blowing hot air at 80° C., and the resin composition was softened by blowing hot air while measuring the temperature (T1 and T2) in the same manner as in Example 1.

[0151] As in Example 1, the resin composition was easily broken, and the miniature transistors could be easily separated from the circuit board.

[0152] Thereafter, the miniature transistors ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com