Heat-resistant adhesive sheet

An adhesive sheet, heat-resistant technology, applied in the direction of film/sheet adhesives, adhesives, electrical components, etc., can solve the problem of contamination of silicone residues, etc., and achieve the effect of high dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

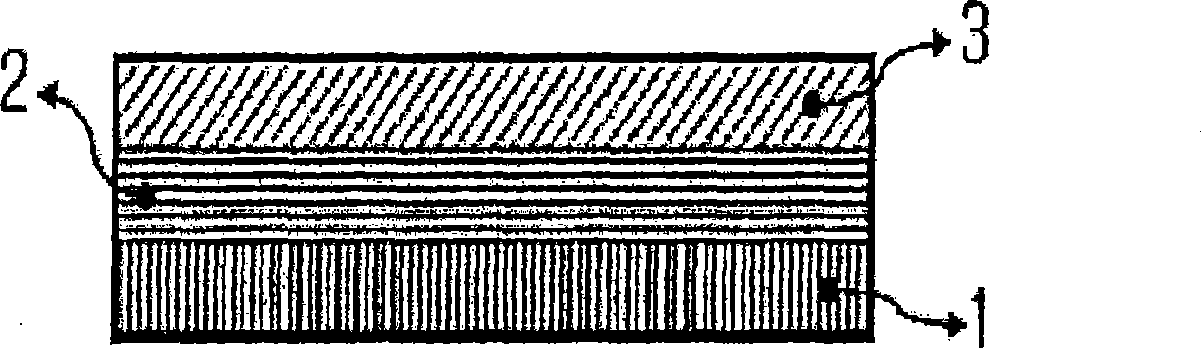

Image

Examples

Embodiment approach 1

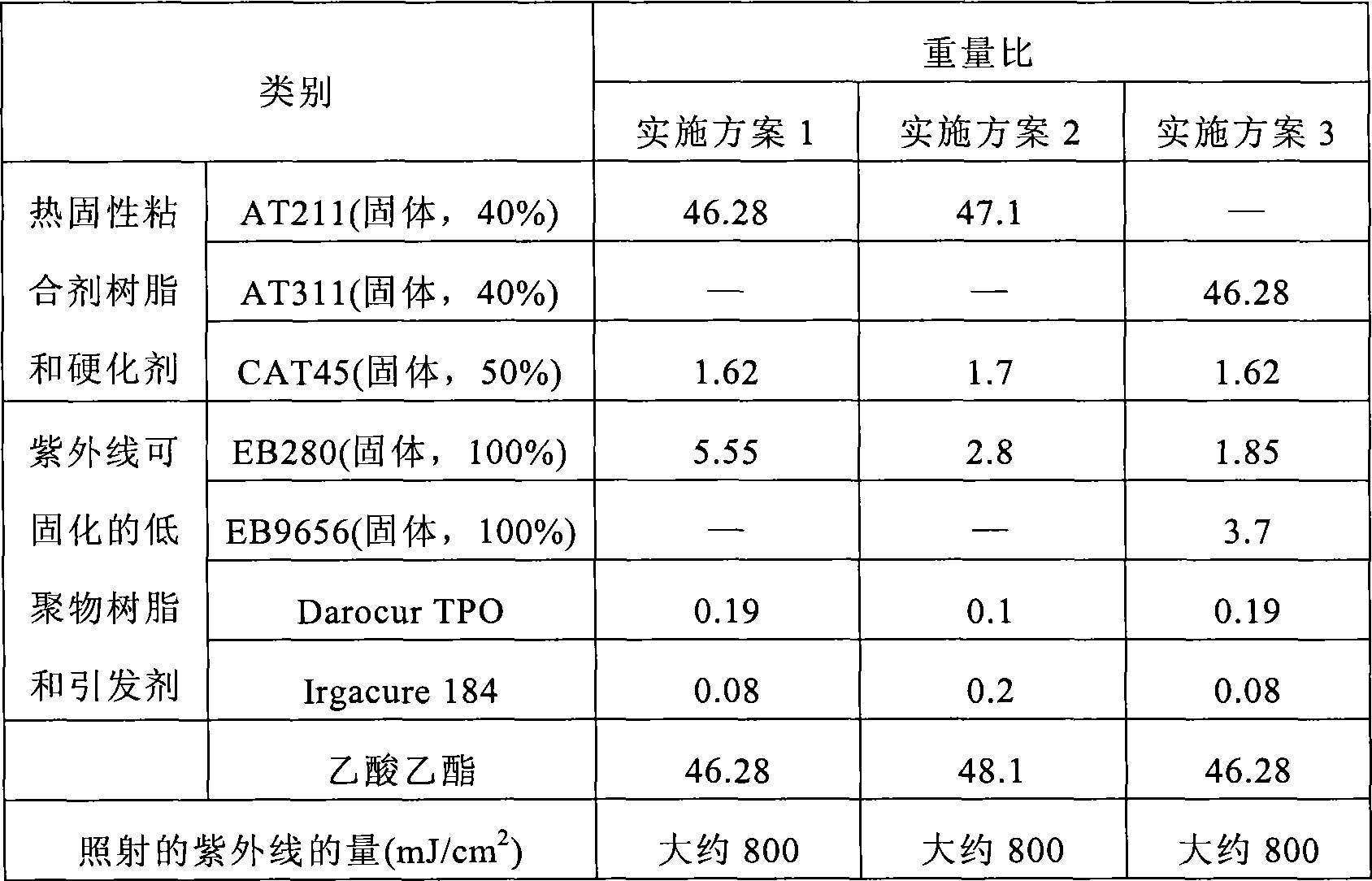

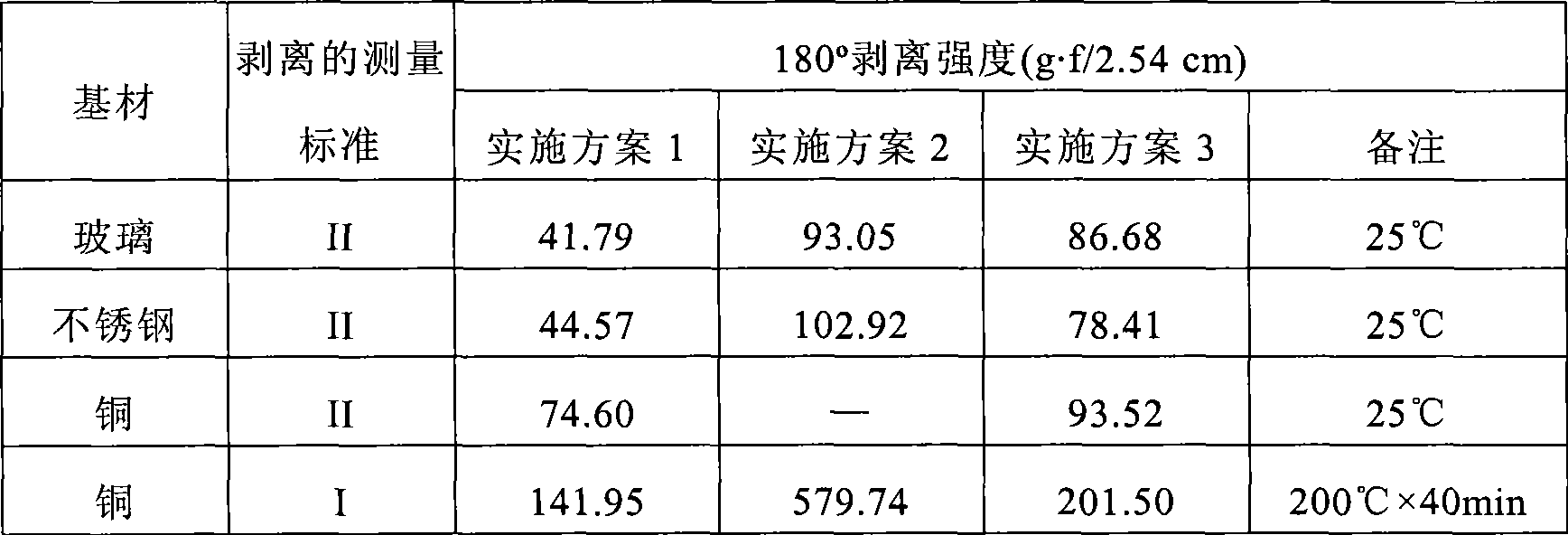

[0056] In order to prepare a UV-curable thermosetting adhesive, for 100 parts by weight of the total liquid, the following were used: 46.28 parts by weight of acrylic adhesive resin (AT-211, commercially available from Samwon Co.), 1.62 parts by weight Parts of isocyanate hardener (CAT-45, commercially available from Samwon Co.), 5.55 parts by weight of urethane acrylate (which is an energy ray-curable oligomer) (EB280, commercially available from Cytec Co.), 0.19 parts by weight of 2,4,6-trimethylbenzoyl-diphenylphosphine (Darocur TPO, commercially available from Ciba Co.), 0.08 parts by weight of hydroxycyclohexylbenzophenone (Irgacure184, commercially available from Ciba Co.) (which is an ultraviolet initiator) and 46.28 parts by weight of ethyl acetate solvent. Then, the adhesive prepared above was coated on a heat-resistant substrate polyimide film (25NPI, commercially available from Kaneka Co., 25 µm) in a thickness of 10 µm, and the resulting film was dried. Subsequent...

Embodiment approach 2

[0058] In order to prepare a UV-curable thermosetting adhesive, for 100 parts by weight of the total liquid, the following were used: 47.1 parts by weight of acrylic adhesive resin (AT-211, commercially available from Samwon Co.), 1.7 parts by weight Parts of isocyanate hardener (CAT-45, commercially available from Samwon Co.), 2.8 parts by weight of urethane acrylate (which is an energy ray-curable oligomer) (EB280, commercially available from Cytec Co.), 0.1 parts by weight of 2,4,6-trimethylbenzoyl-diphenylphosphine (Darocur TPO, commercially available from Ciba Co.), 0.2 parts by weight of hydroxycyclohexylbenzophenone (Irgacure184, commercially available from Ciba Co.) (which is an ultraviolet initiator) and 48.1 parts by weight of ethyl acetate solvent. Then, the adhesive prepared above was coated on a heat-resistant substrate polyimide film (25NPI, commercially available from Kaneka Co., 25 µm) in a thickness of 10 µm, and the resulting film was dried. Subsequently, in...

Embodiment approach 3

[0060]In order to prepare a UV-curable thermosetting adhesive, for 100 parts by weight of the total liquid, the following were used: 46.28 parts by weight of acrylic adhesive resin (AT-211, commercially available from Samwon Co.), 1.62 parts by weight Parts of isocyanate hardener (CAT-45, commercially available from Samwon Co.), 1.85 parts by weight of urethane acrylate (which is an energy ray-curable oligomer) (EB280, commercially available from Cytec Co.), 3.7 parts by weight of phenyl novolac (novlac) acrylate (EB9656, commercially available from Cytec Co.) (which is an energy ray curable oligomer), 0.19 parts by weight of 2,4,6-trimethyl Benzoyl-diphenylphosphine (Darocur TPO, commercially available from Ciba Co.), 0.08 parts by weight of hydroxycyclohexylbenzophenone (Irgacure184, commercially available from Ciba Co.) (it is an ultraviolet initiator) and 46.28 Parts by weight of ethyl acetate solvent. Then, the adhesive prepared above was coated on a heat-resistant subst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com