High-temperature-resistant ultra-silent explosion-proof sealed capacitor

An ultra-quiet, high-temperature-resistant technology, applied in the field of capacitors, can solve the problems of labor-intensive and low-efficiency, and achieve the effect of ensuring noise reduction, good high temperature resistance and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

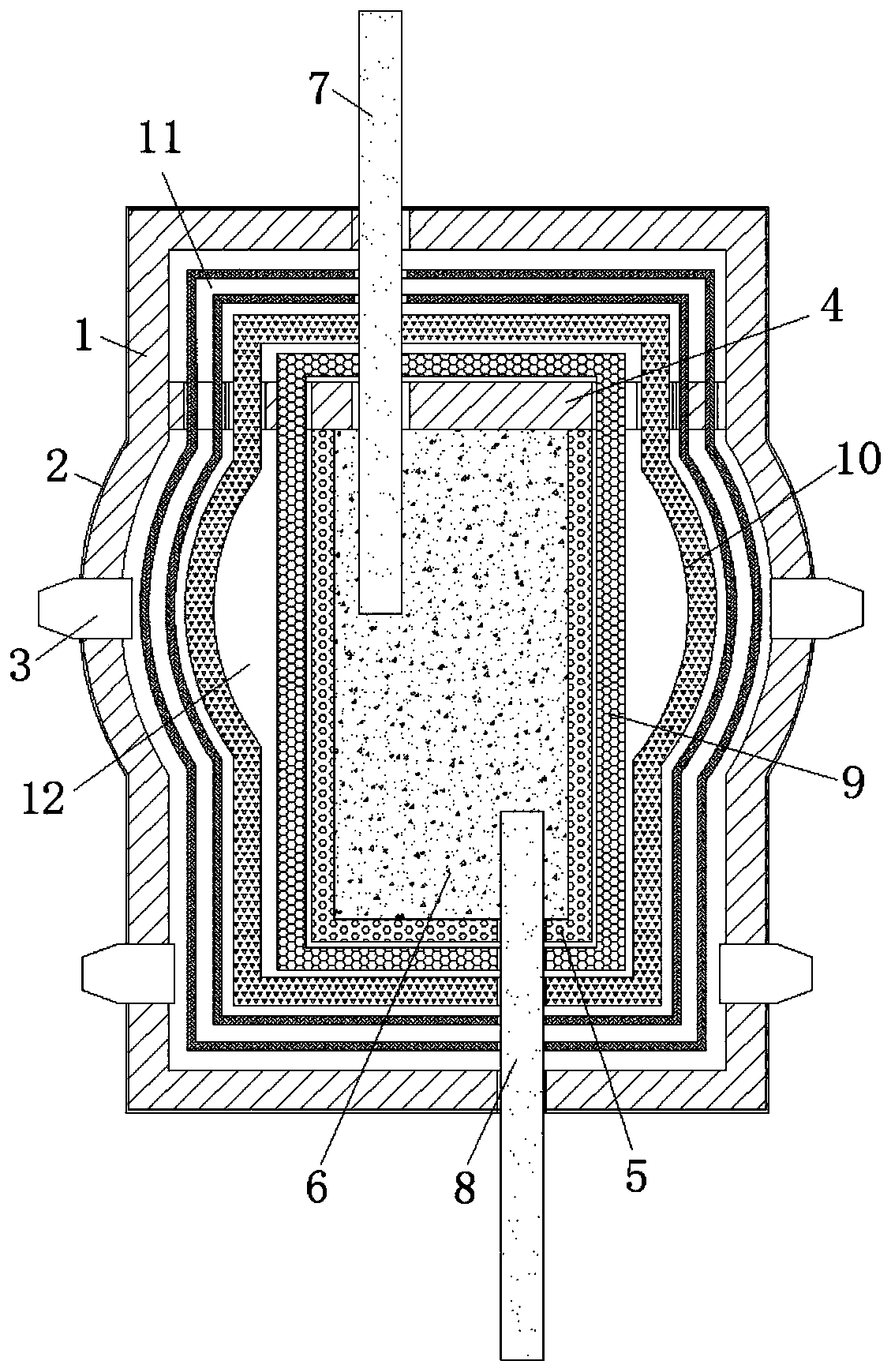

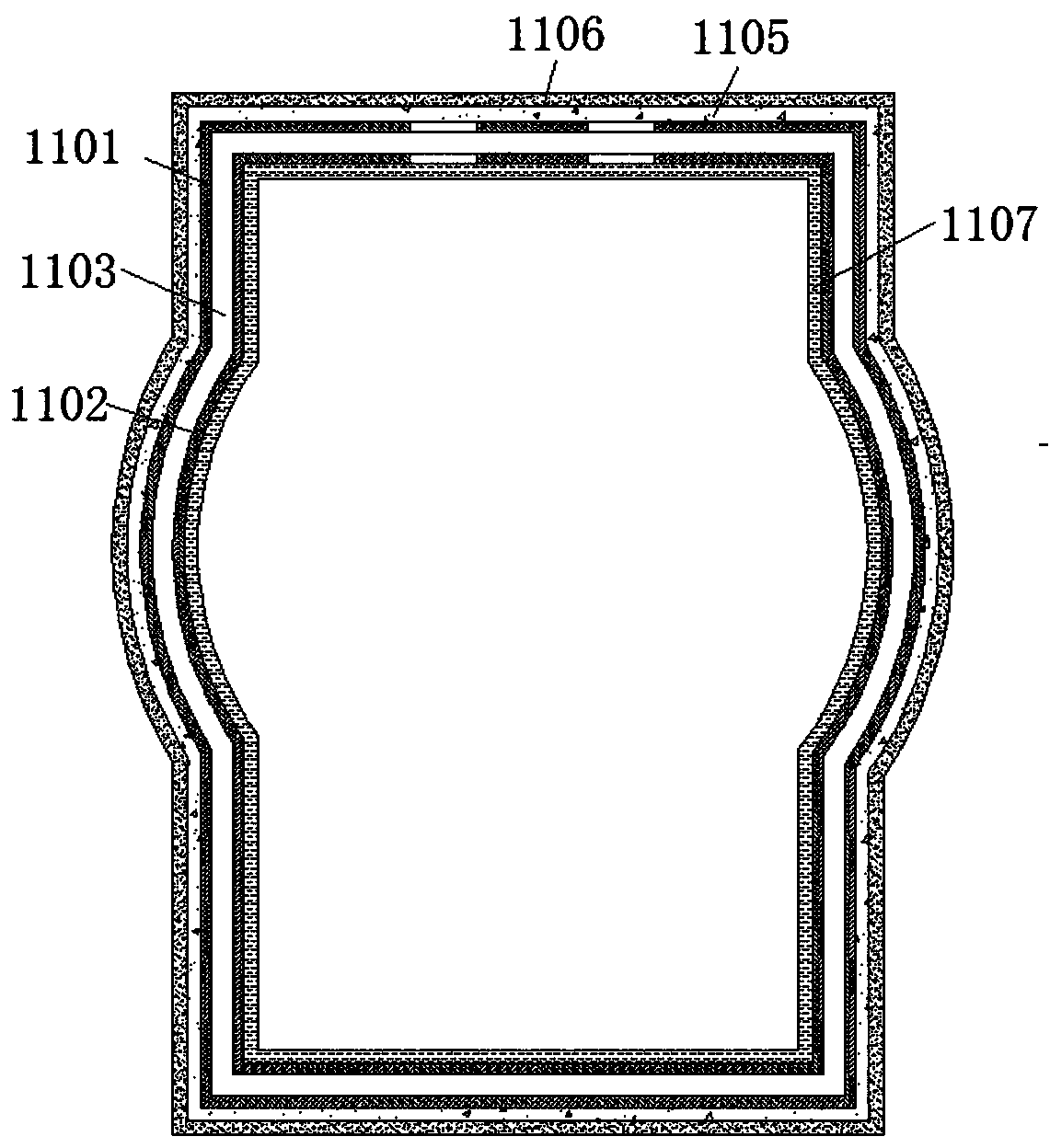

[0028] refer to figure 1 , a high-temperature-resistant ultra-quiet explosion-proof sealed capacitor, including a metal case 1, the outer surface of the metal case 1 is sprayed with medium green gray baking paint 2, the middle and bottom of the metal case 1 are equipped with sensors 3, and the upper end of the inner wall of the metal case 1 is fixed. Tantalum cover 4, the middle part of the lower end of the tantalum cover 4 is connected with an insulating layer 5, the inner side of the insulating layer 5 is provided with a tantalum powder sintered block 6, the upper end of the tantalum powder sintered block 6 is fixedly connected with a positive nickel wire 7, and the lower end of the tantalum powder sintered block 6 deviates from One side of the positive nickel wire 7 is fixedly connected with the negative copper wire 8, the outer side of the insulating layer 5 is provided with a sound-absorbing layer 9, the outer side of the sound-absorbing layer 9 is provided with a heat-res...

Embodiment 2

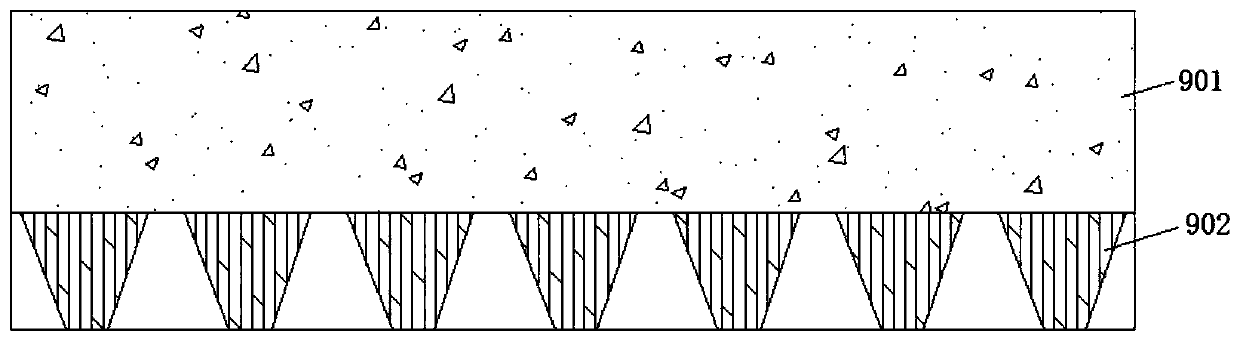

[0031] Such as figure 1 and 2 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the sound-absorbing layer 9 includes an adhesive layer 901 and a porous layer 902. The porous layer 902 is glued and fixed to the adhesive layer 901, and the porous layer 902 is located close to the insulating layer 5. side.

[0032] In this embodiment, the porous layer 902 is glued and fixed inside the adhesive layer 901 , so as to absorb the noise generated by the capacitor, thereby ensuring the sound-absorbing effect of the capacitor.

Embodiment 3

[0034] Such as figure 1 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the heat-resistant layer 10 is a mixture of methyl-terminated vinyl silica gel G795, heat-resistant agent, and silicon nitrogen.

[0035] In this embodiment, the heat-resistant layer 10 is made by mixing methyl-terminated vinyl silica gel G795, heat-resistant agent, and silicon nitrogen. Since vinyl silica gel G795 and heat-resistant agent have good heat resistance, and the mixture of the two will not When chemical reaction occurs, the performance of the substance will not change, so that the heat-resistant layer 10 achieves a good heat-resistant effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com