Preparation of chitosan in fungal cell wall

A chitosan and fungal cell wall technology, applied in the field of chitosan extraction, can solve the problems of high energy consumption, environmental pollution, long processing time, etc., and achieve the effects of low pollution, reduced production costs, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

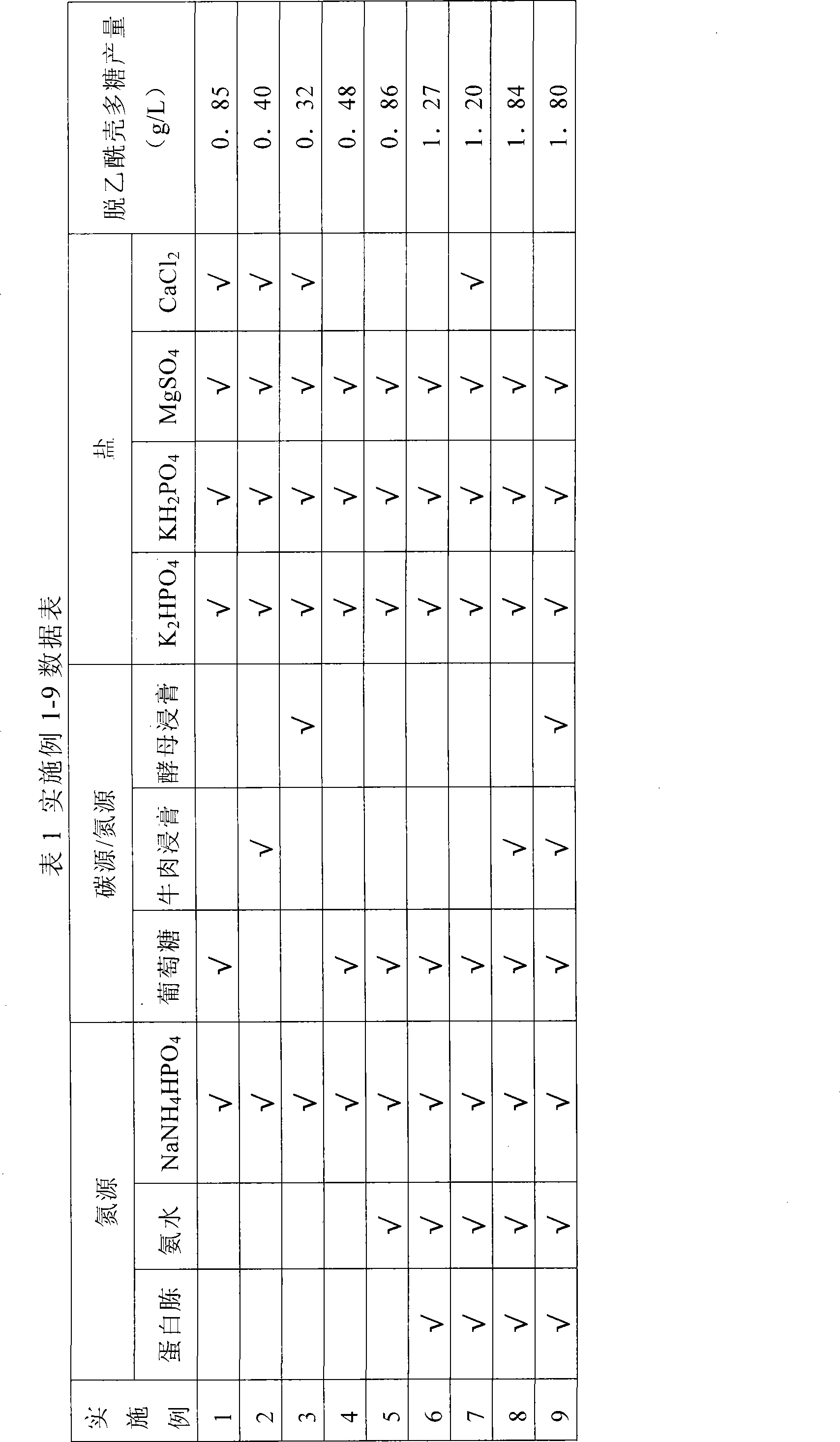

Examples

Embodiment 1

[0021] The slant culture (PDA medium) of Actinomucor taiwanensis preserved at 4°C was directly inoculated into a 500ml shake flask containing 100ml of fresh seed culture solution, and cultured at 30°C with shaking at 280rpm for 48h. The seed medium adopts E2 medium, and each liter of seed medium contains 40g of glucose (that is, 20g of carbon source), 3.5g of NaNH 4 HPO 4 4H 2 O (ie 0.23g nitrogen source), 7.5g K 2 HPO 4 ·3H 2 O, 3.7gKH 2 PO 4 , 0.12g MgSO 4 , 0.56g CaCl 2 After 2 days of shake flask culture, the original seed was obtained, and the original seed was inoculated in a 5L fermenter.

[0022] Fill the fermenter with 40% of the liquid content, use 10 times the amount of seed medium content per liter of fermentation liquid, inoculate with 5% of the inoculum, control the temperature at 25-30°C, and the rotation speed is 100-400rpm. 6d.

[0023] The cell mass was recovered from the fermentation broth, gauze filter or centrifuged, the cells were treated with 1...

Embodiment 2

[0026] The slant culture of Actinomucor taiwanensis preserved at 4°C was directly inoculated into a 500ml shake flask containing 100ml of fresh seed culture solution. Carry out shaking flask culture as described in Example 1, the difference is that every liter of seed medium contains 20g carbon source (beef extract), 0.23g nitrogen source (3.5g NaNH 4 HPO 4 4H 2 O), 7.5g K 2 HPO 4 ·3H 2 O, 3.7g KH 2 PO 4 , 0.12g MgSO 4 , 0.56g CaCl 2 . After shaking the flask for 2 days, the original seed was obtained in the shake flask, and the original seed was used to inoculate the culture medium of the fermenter.

[0027] The amount of liquid in the fermenter is operated according to the amount of liquid in Example 1, and the amount of liquid in the fermenter is filled by 40%, and 5 times the amount of seed culture medium is used in the middle of every liter of fermented liquid. Inoculate with 5% inoculum amount, control the temperature at 25-30° C., rotate at 100-400 rpm, and fe...

Embodiment 3

[0030] Shake flask culture was carried out as described in Example 1, and cultured to a suitable concentration, generally when the dry weight of the obtained mycelium reached between 10.5 mg / ml and 15.0 mg / ml, it was used as a fermenter seed.

[0031]The amount of liquid in the fermentation tank was operated according to the amount of liquid in Example 1, except that yeast extract was used as a carbon source in the fermentation liquid, and the amount of yeast extract added was 25.0 g / L. The product was separated and extracted according to the method of Example 2, and the obtained dry cell weight was 7.1g / L to obtain chitosan 0.32g / L. The yield was 4.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com