Low crack sensitivity steel plate with yield strength 500MPa and manufacturing method thereof

A technology of yield strength and manufacturing method, applied in the field of iron and steel metallurgy, can solve the problems of high smelting cost, high price, complex manufacturing process, etc., and achieve the effects of excellent welding performance, loose process system, and reduced raw material cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

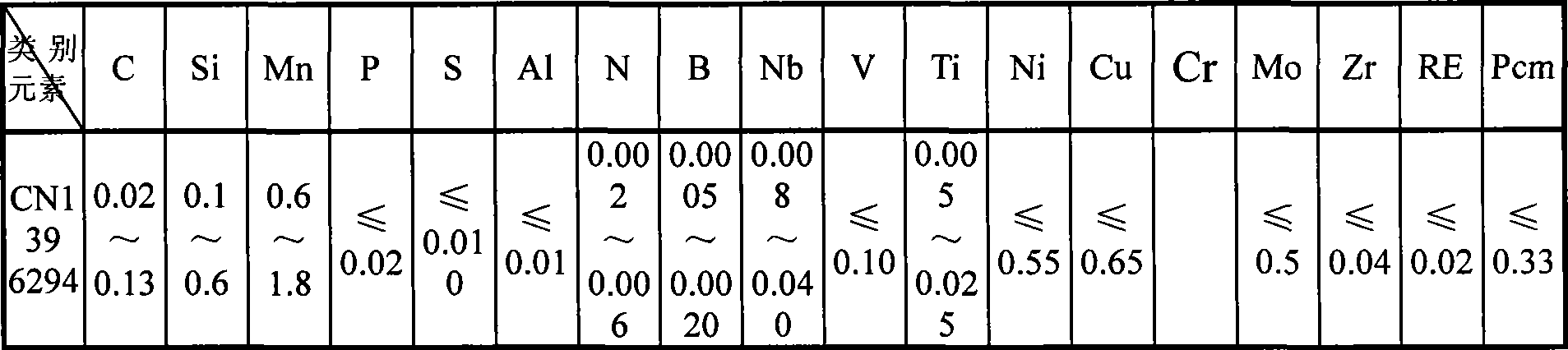

[0041] The proportion of chemical elements in the steel of the present invention is: C: 0.01%, Si: 0.65%, Mn: 2.00%, P≤0.010%, S≤0.006%, Nb: 0.090%, Al: 0.050%, Ti: 0.030% , B: 0.0025%, the balance is Fe and unavoidable impurities.

[0042] The manufacturing method is as follows: the heating temperature is 1080°C, and the heat preservation is 120 minutes; the starting rolling temperature of the first stage rolling is 1060°C, and the thickness of the rolled piece is 90mm; the starting rolling temperature of the second stage rolling is 780°C, and the final rolling temperature is 740°C, the thickness of the finished steel plate is 30mm; the cooling rate of the steel plate is 15°C / S, and the termination temperature is 450°C.

Embodiment 2

[0044] The proportion of chemical elements in the steel of the present invention is: C: 0.02%, Si: 0.60%, Mn: 1.80%, P≤0.010%, S≤0.006%, Nb: 0.080%, Al: 0.060%, Ti: 0.025% , B: 0.0020%, the balance is Fe and unavoidable impurities.

[0045] The manufacturing method is as follows: the heating temperature is 1100°C, and the heat preservation is 160 minutes; the starting rolling temperature of the first stage rolling is 1090°C, and the thickness of the rolled piece is 100mm; the starting rolling temperature of the second stage rolling is 780°C, and the final rolling temperature is 770°C, the thickness of the finished steel plate is 40mm; the cooling rate of the steel plate is 5°C / S, and the termination temperature is 560°C.

Embodiment 3

[0047] The proportion of chemical elements in the steel of the present invention is: C: 0.04%, Si: 0.50%, Mn: 1.65%, P≤0.010%, S≤0.006%, Nb: 0.060%, Al: 0.055%, Ti: 0.020% , B: 0.0015%, the balance is Fe and unavoidable impurities.

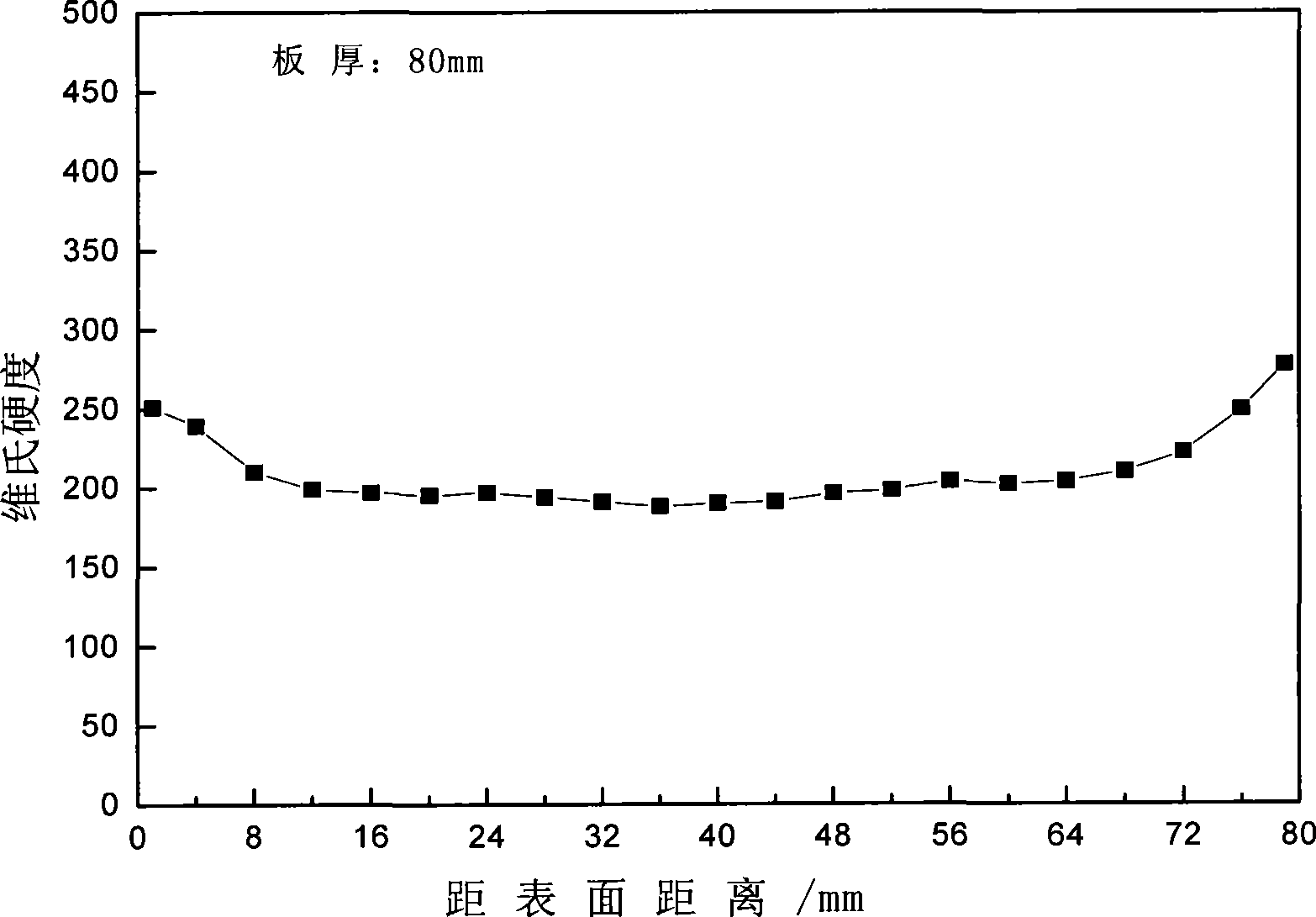

[0048] The manufacturing method is as follows: the heating temperature is 1120°C, and the heat preservation is 150 minutes; the starting temperature of the first stage rolling is 1100°C, and the thickness of the rolled piece is 150mm; the starting temperature of the second stage rolling is 800°C, and the final rolling temperature is 790°C, the thickness of the finished steel plate is 60mm; the cooling rate of the steel plate is 12°C / S, and the termination temperature is 500°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com