Austenic stainless steel strip and manufacturing method thereof

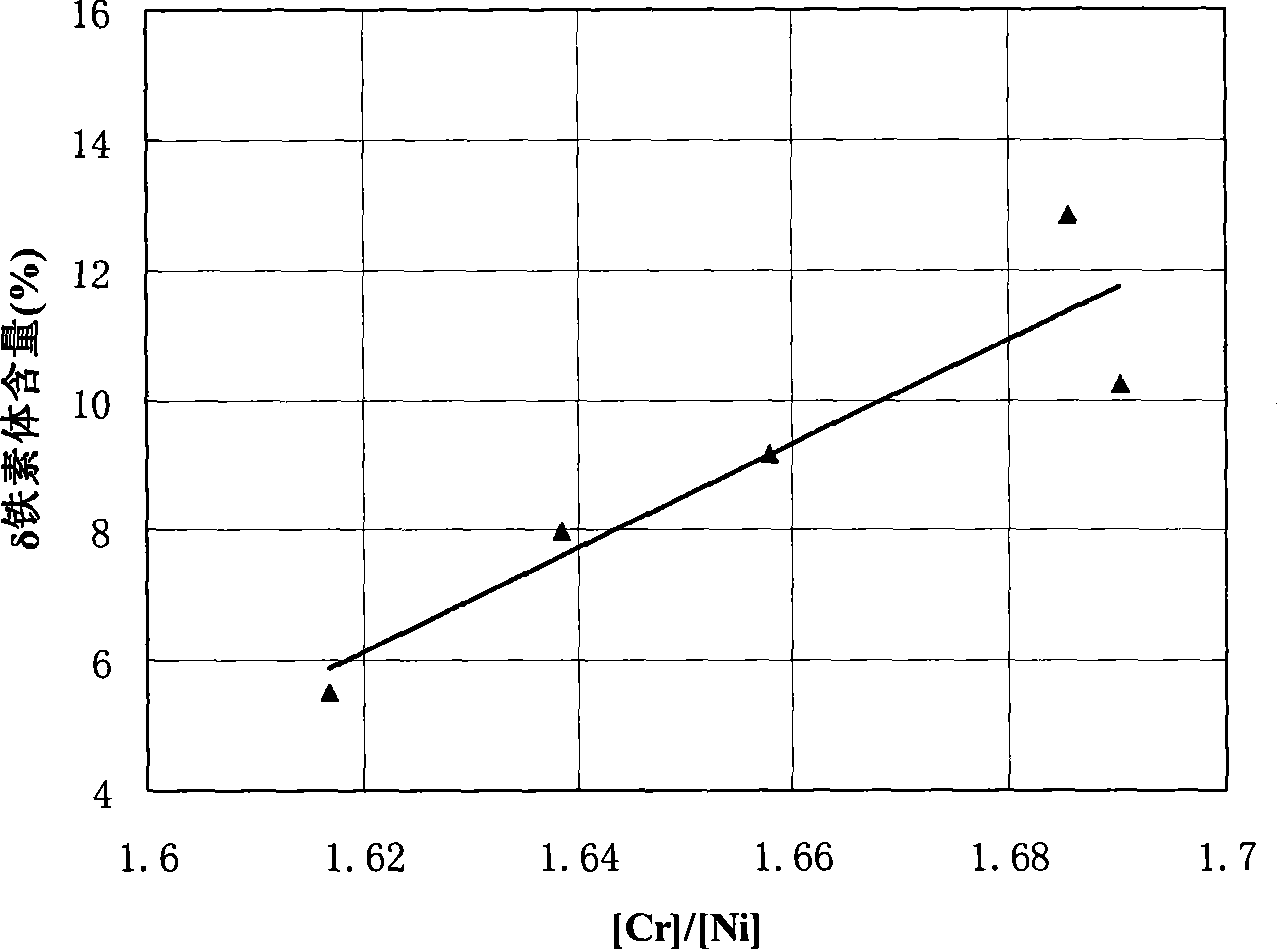

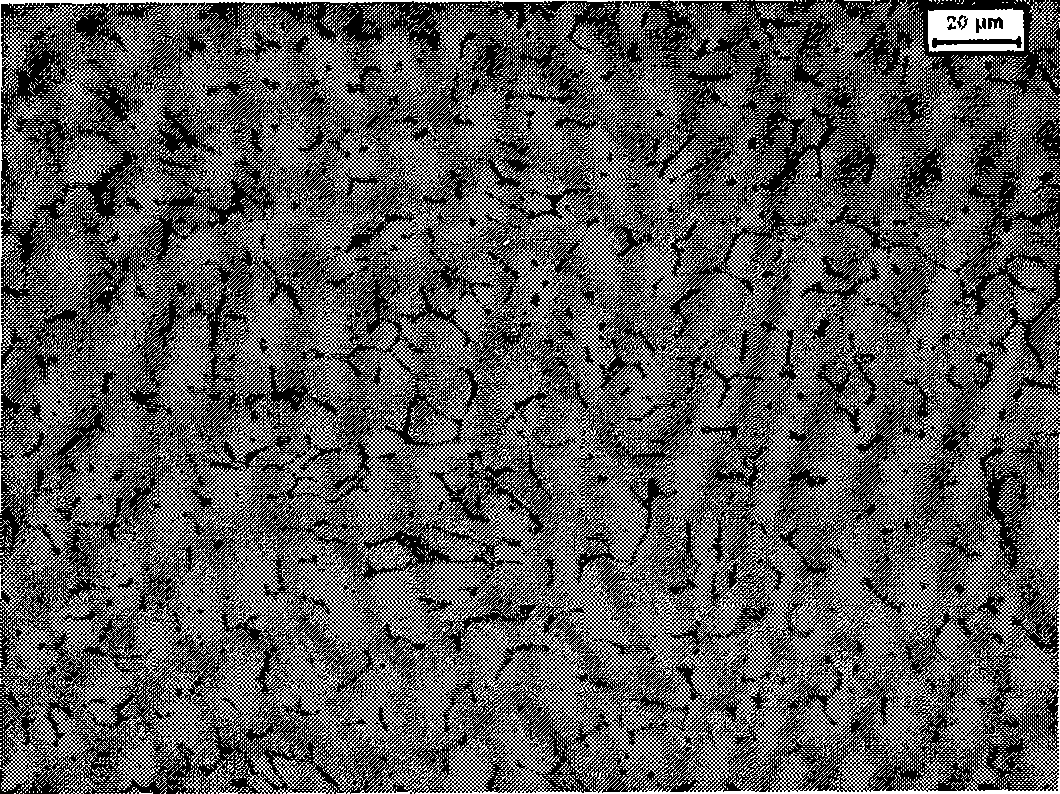

A technology of austenitic stainless steel and manufacturing method, which is applied in the direction of manufacturing tools, metal rolling, temperature control, etc., can solve the problems of reduced pitting resistance, aggravated crack tendency, reduced service performance, etc., and achieves the reduction of ferrite content , Reduce the amount of ferrite, improve the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

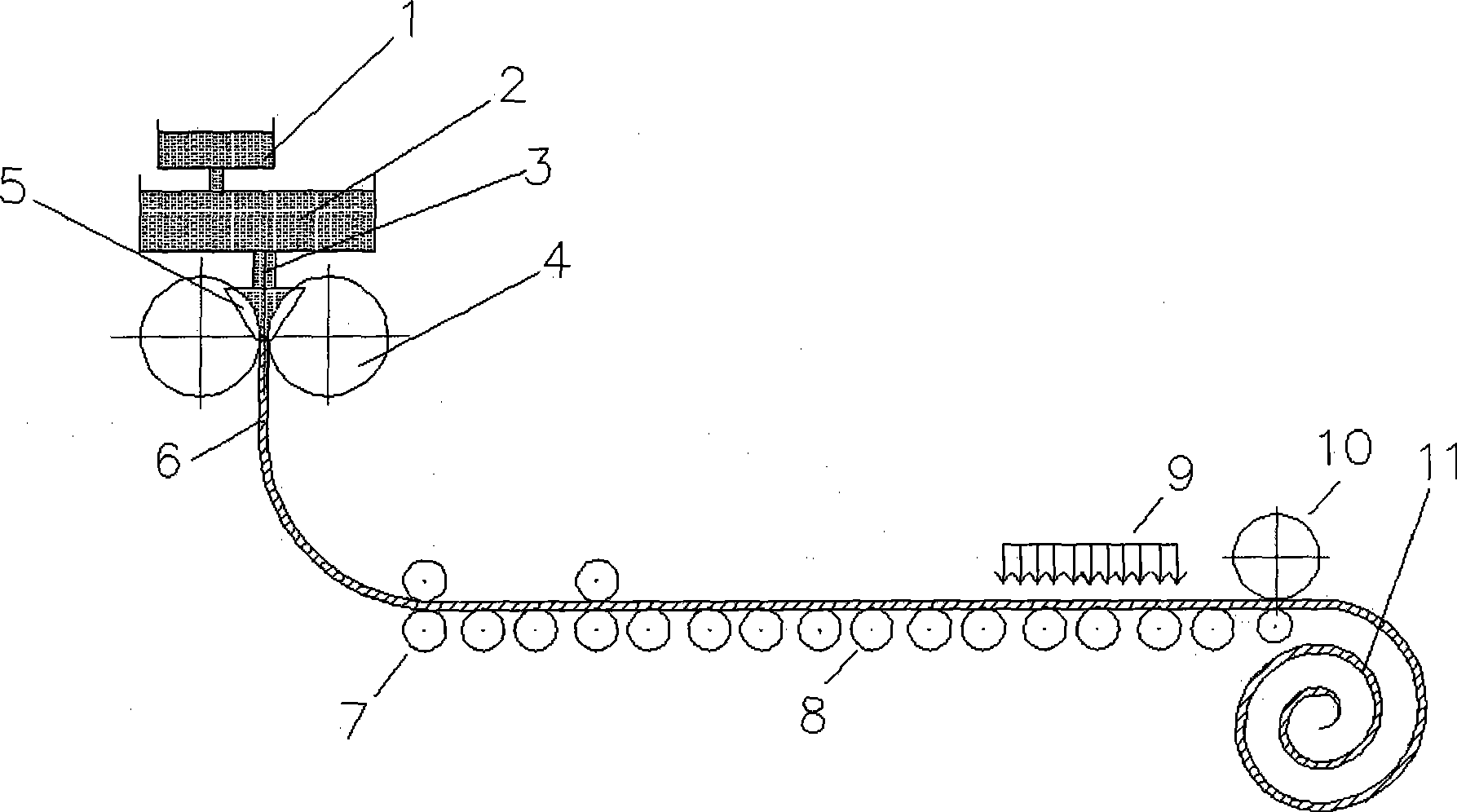

[0054] Embodiment 1 comprises the steps in turn:

[0055] 1) Chemical composition of molten steel (wt%): C=0.08%, Si=0.4%, Mn=2%, P=0.021%, S=0.006%, Cr=19%, Ni=7%, Cu=0.5%, The balance is Fe and unavoidable impurities;

[0056] 2) Smelting according to the above ingredients, forming a 2.3mm cast strip through twin-roll thin strip continuous casting, controlling cooling, and coiling the cast strip at 590°C;

[0057] 3) Pickling is then carried out, and then cold rolling is carried out. The reduction ratio of the first cold rolling is 14%. The strip steel after cold rolling is annealed in a bell annealing furnace. The annealing temperature is 1080° C., and the annealing time is 7 minutes ;

[0058] 4) pickling and cold rolling again, the reduction rate of the second cold rolling is 45%, the strip steel after cold rolling is annealed in a bell annealing furnace, the annealing temperature is 1100 ℃, and the annealing time is 3.5min;

[0059] 5) pickling and cold rolling again,...

Embodiment 2

[0062] Embodiment 2 comprises the steps in turn:

[0063]1) Chemical composition of molten steel (wt%): C=0.12%, Si=0.85%, Mn=0.8%, P=0.035%, S=0.03%, Cr=17%, Ni=9.3%, Cu=0.3%, The balance is Fe and unavoidable impurities;

[0064] 2) Smelting according to the above ingredients, forming a 2.0mm cast strip through twin-roll thin strip continuous casting, controlling cooling, and coiling the cast strip at 600°C;

[0065] 3) Carry out pickling then, carry out cold rolling again, the reduction rate of first cold rolling is 15%, the strip steel after cold rolling is annealed in bell annealing furnace, and annealing temperature is 1050 ℃, and annealing time is 6min ;

[0066] 4) pickling and cold rolling again, the reduction rate of the second cold rolling is 45%, the strip steel after cold rolling is annealed in a bell annealing furnace, the annealing temperature is 1150 ° C, and the annealing time is 4min;

[0067] 5) Pickling and cold rolling again, the third cold rolling redu...

Embodiment 3

[0070] Embodiment 3 comprises the steps in turn:

[0071] 1) Chemical composition of molten steel (wt%): C=0.04%, Si=1%, Mn=1.56%, P=0.04%, S=0.01%, Cr=17.4%, Ni=10%, Cu=0.25%, The balance is Fe and unavoidable impurities;

[0072] 2) Smelting according to the above ingredients, forming a 2.5mm cast strip through twin-roll thin strip continuous casting, controlling cooling, and coiling the cast strip at 600°C;

[0073] 3) Pickling is then carried out, and then cold rolling is carried out. The reduction ratio of the first cold rolling is 15%. The strip steel after cold rolling is annealed in a bell annealing furnace. The annealing temperature is 1120° C., and the annealing time is 4 minutes ;

[0074] 4) pickling and cold rolling again, the reduction ratio of the second cold rolling is 40%, the strip steel after cold rolling is annealed in a bell annealing furnace, the annealing temperature is 1070 ℃, and the annealing time is 7min;

[0075] 5) pickling and cold rolling agai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com