Light emitting diode apparatus having heat conductive substrate

A technology of light-emitting diodes and bases, which is applied to semiconductor devices, semiconductor/solid-state device components, electrical components, etc., can solve problems such as component failure, lattice defects, and complicated manufacturing processes, and achieve conductive processing problems, long and The effect of stable working life and high light output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

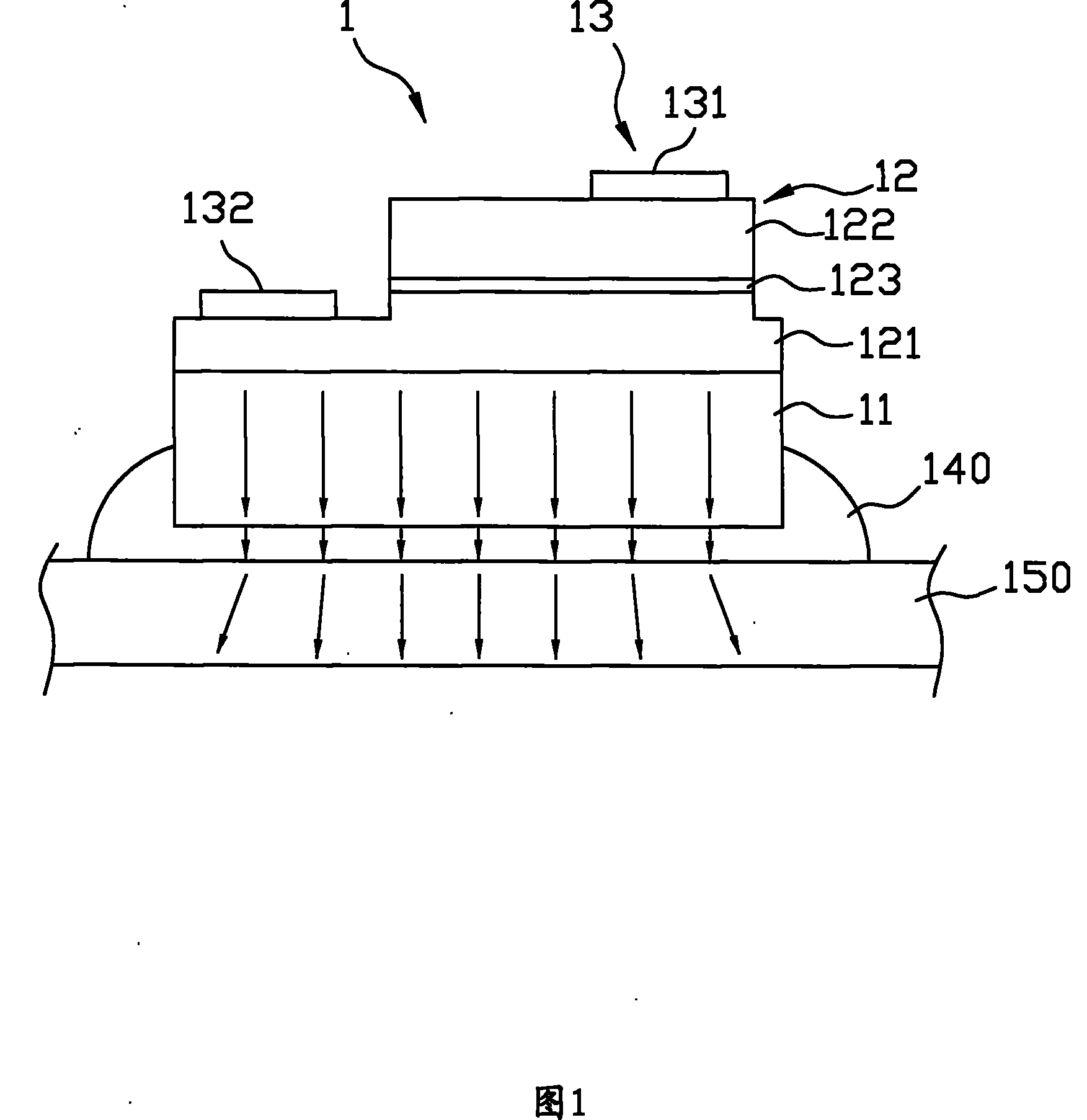

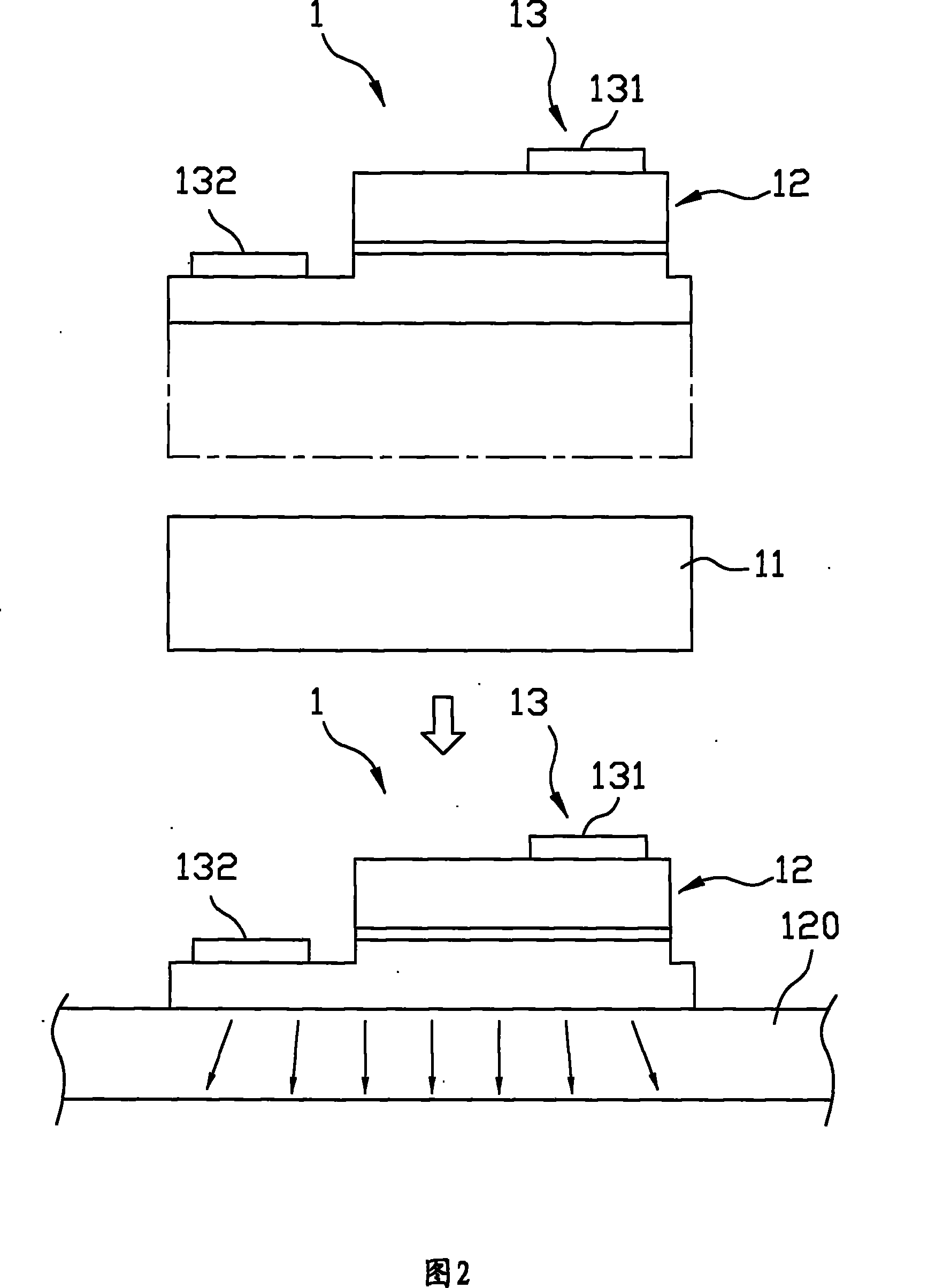

[0024] The light-emitting diode device with a heat-conducting base of the present invention will be described in detail below with reference to the drawings and embodiments.

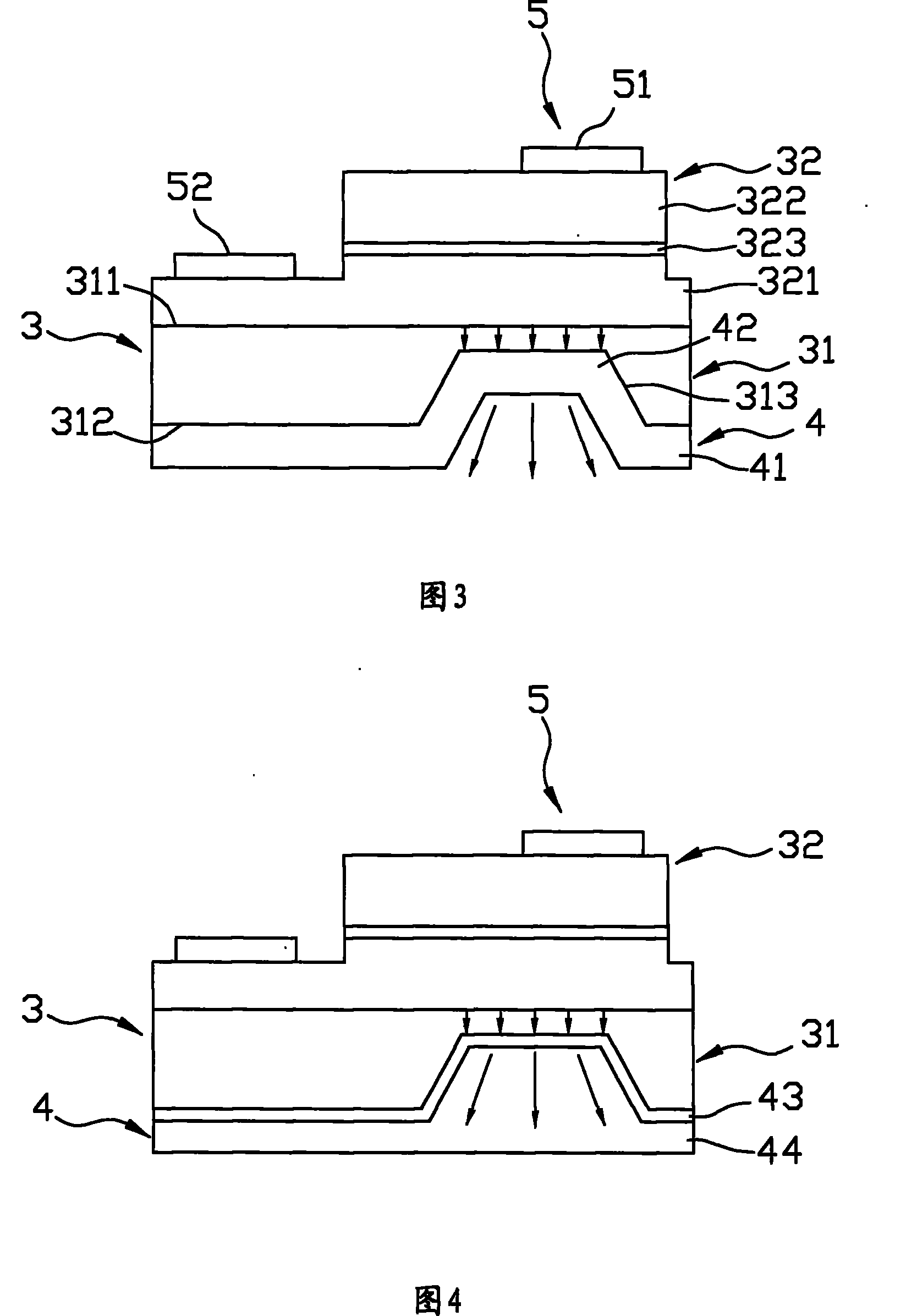

[0025] Referring to FIG. 3 , the first preferred embodiment of the light-emitting diode device with heat-conducting base of the present invention includes: a light-emitting diode chip 3 , a heat-conducting base 4 and a set of electrode units 5 .

[0026] This light emitting diode chip 3 has a base material 31 and a layer of action film 32, which is similar to the existing light emitting diode chip. Made of sapphire, it includes a top surface 311, a bottom surface 312 opposite to the top surface 311, and at least one filling hole 313 formed on the bottom surface 312. In this example, only a single filling hole 313 is shown for illustration .

[0027] This layer of action film 32 is similar to the action film 12 of the current light-emitting diode chip 1, and is usually selected from gallium nitride semic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com