Method and device for circulation and regeneration of acidic waste etching liquid

A waste etching solution recycling technology, applied to the improvement of process efficiency, photography process, instruments, etc., can solve the problems of high power consumption, low-grade sponge copper, and low efficiency of copper powder, etc., to reduce processing and operating costs , reduce sewage discharge, reduce the effect of environmental protection pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

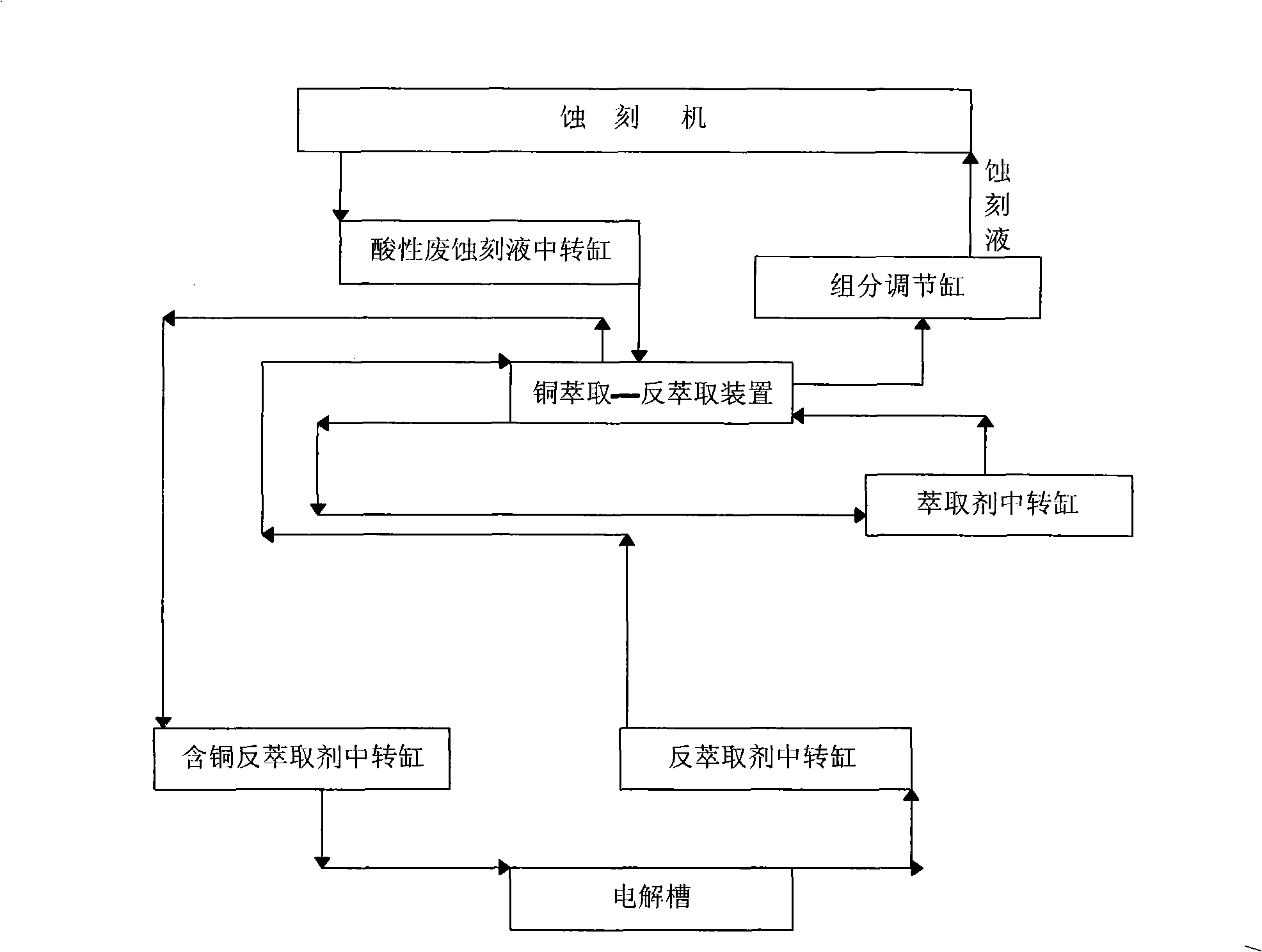

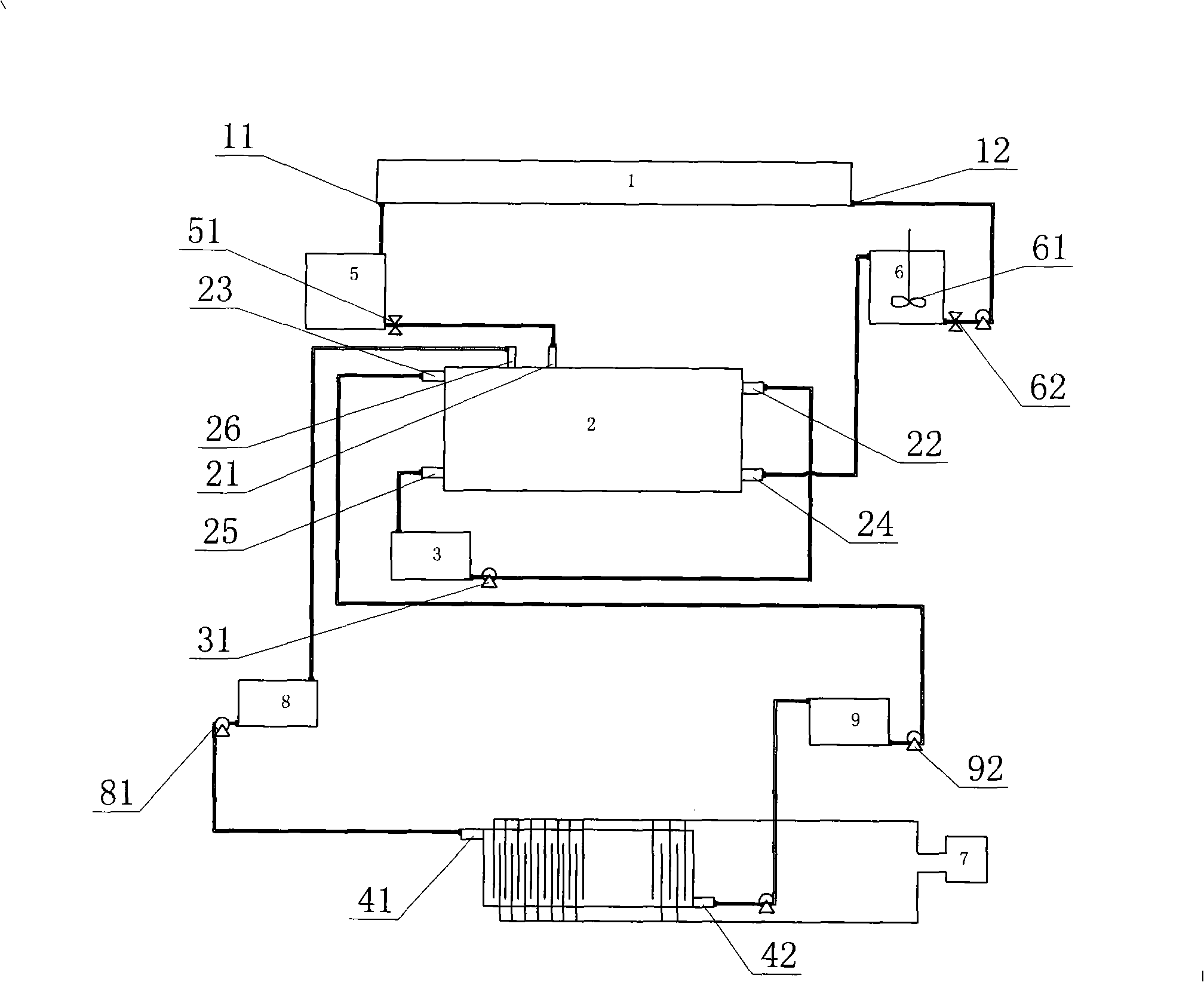

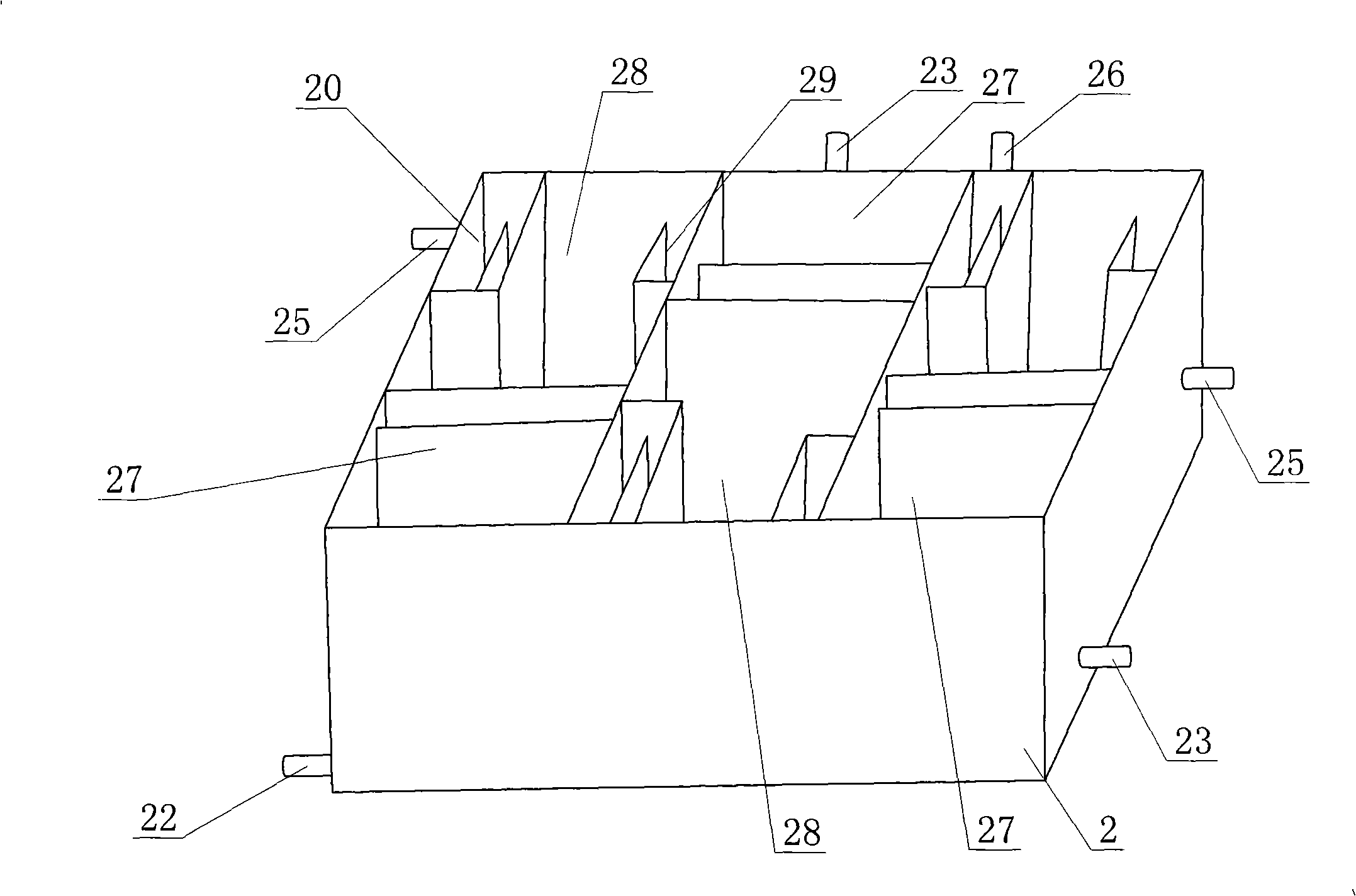

[0019] Such as figure 1 Shown, the method for recycling and regenerating acidic waste etching solution of the present invention comprises the following recycling steps:

[0020] Copper separation and component deployment cycle of acidic waste etching solution: the acidic waste etching solution produced after etching by acid etching machine is extracted and removed by copper extraction agent in copper extraction-stripping mechanism 2 to form copper-extracting waste etching solution. Copper waste etching solution is returned to the acid etching machine 1 for recycling after the components are adjusted to meet the requirements of production;

[0021] Copper extractant circulation: the copper extractant extracts copper in the copper extraction-stripping mechanism 2 to form a copper-containing copper extractant, and the copper-containing copper extractant fully reacts with the stripping agent to release copper ions to the stripping In the extraction agent, the copper extraction ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com