Vacuum magnetron sputtering coil film coating apparatus

A vacuum magnetron sputtering and coating device technology, applied in sputtering coating, vacuum evaporation coating, ion implantation coating, etc., can solve the problems of low work efficiency, uneven vacuum degree, oil return of oil diffusion pump, etc. , to achieve the effect of improving work efficiency, comprehensive functions, and uniform vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A vacuum magnetron sputtering roll-to-roll coating device of the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

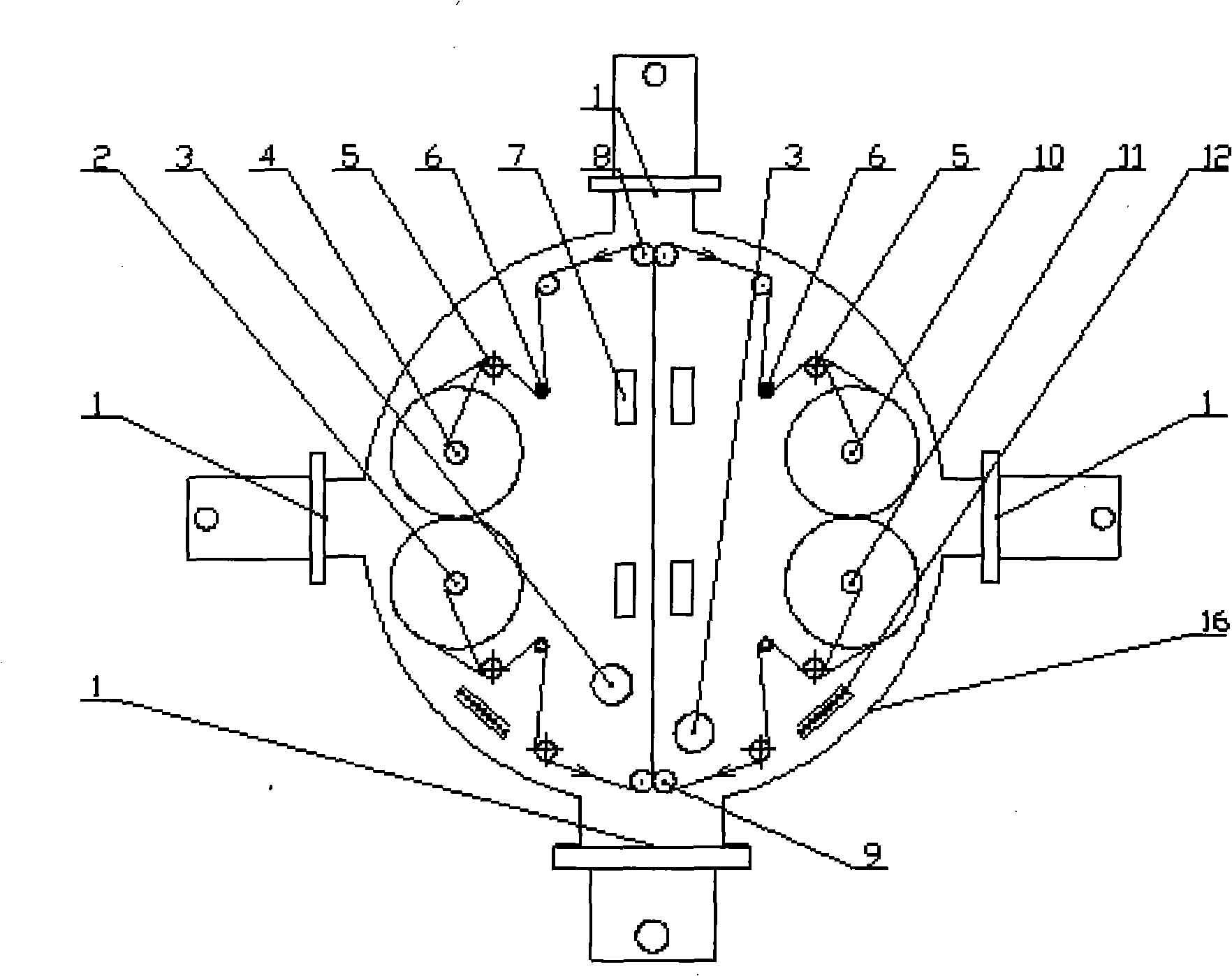

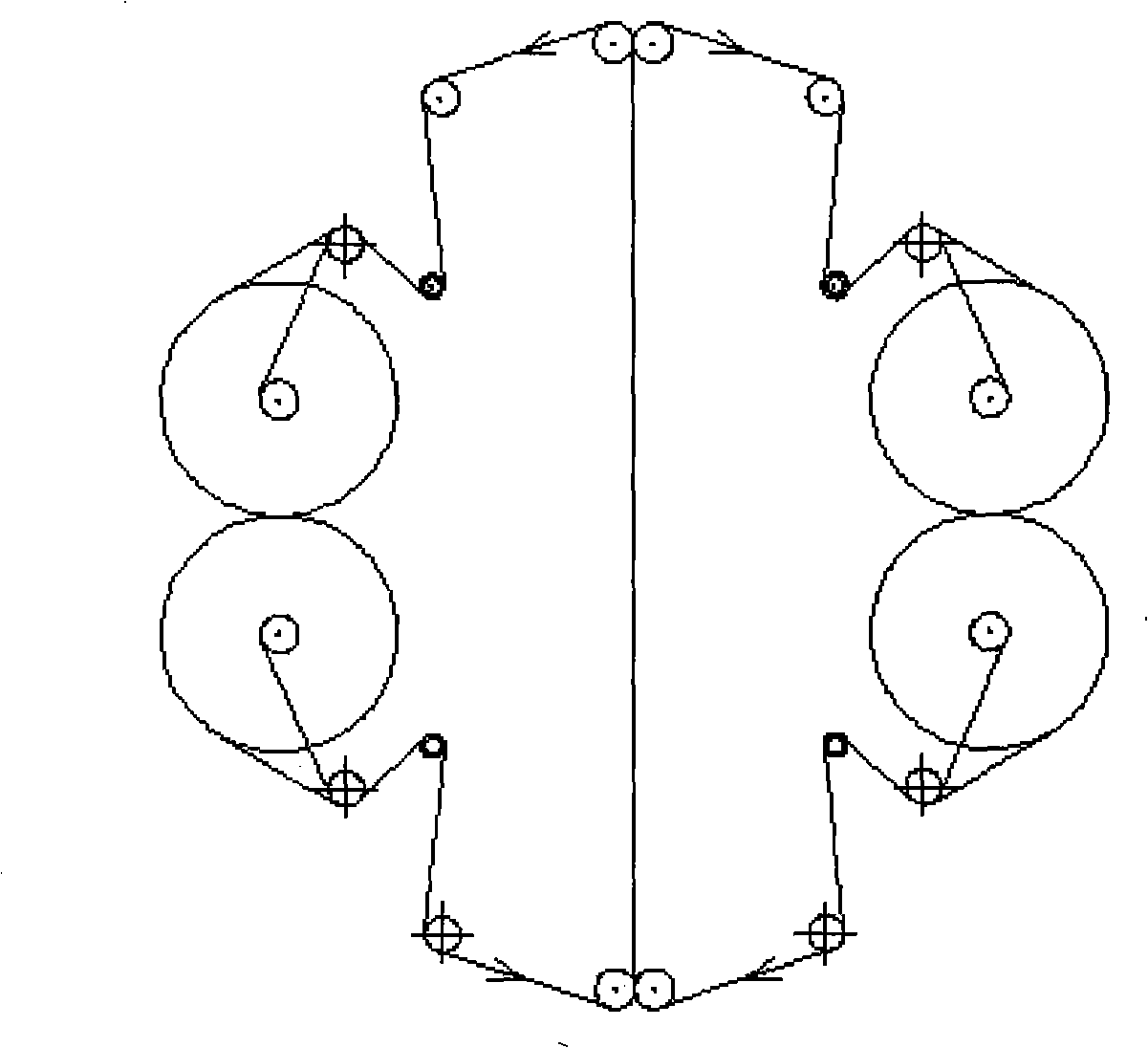

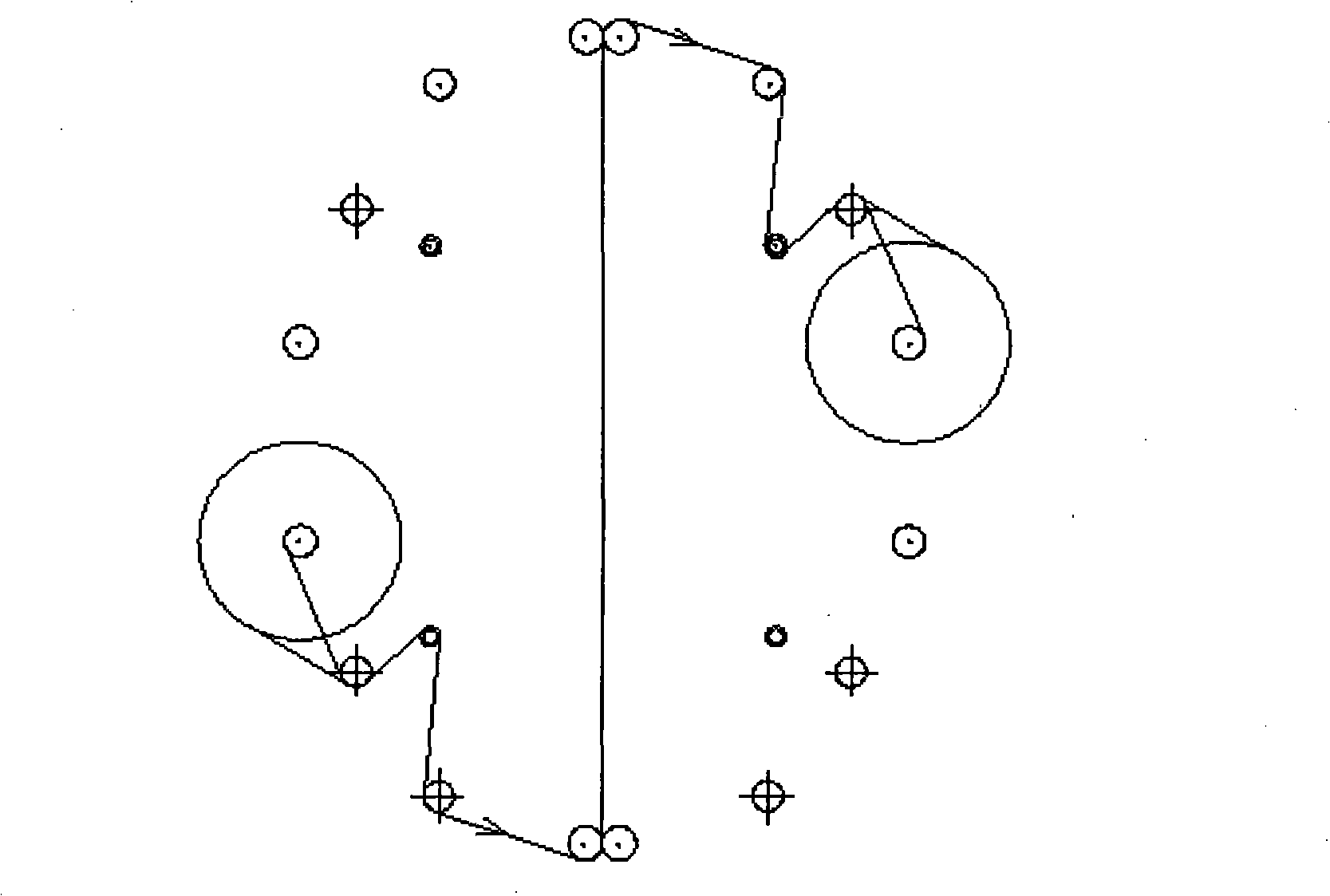

[0023] A vacuum magnetron sputtering winding coating device, such as figure 1 , Figure 7 and Figure 8 As shown, it includes a vacuum chamber 16, a vacuum obtaining system 1, a target 7, a target 7 and a winding system 15, the vacuum chamber 16 is provided with a vacuum obtaining system 1, and the vacuum obtaining system 1 makes the inside of the vacuum chamber 16 It is in a vacuum state during operation, and the magnetron sputtering area in the vacuum cavity 16 is provided with a magnetron sputtering target 7 . There are two rows of target poles 7 for magnetron sputtering, and the two rows of target poles 7 can be arranged in an opposite form, or in a staggered form. Rewinding and unwinding systems 15 are respectively arranged on both sides of the magnetron sputtering area. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com