Emulsified crude oil emulsion laser co-focussing analytical method

A laser confocal and analysis method technology, applied in the field of emulsified crude oil analysis, can solve problems affecting image clarity and resolution, reduce signal-to-noise ratio, etc., and achieve the effect of small divergence, high brightness, and strong directionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Take a few drops of relatively stable emulsion and add it to the groove of the slide glass. The size of the slide glass is 7.5×2.5×0.5cm, the radius of the groove circle is 0.75cm, and the depth is 0.25cm. Then cover it with a cover glass. The size of the cover glass is 1.7×1.7cm, and it is sealed with 502 glue, placed in an incubator, and kept at a temperature of 25 degrees for 24 hours. After the temperature is kept constant until the shape of the droplet is regular, it can be observed with a microscope.

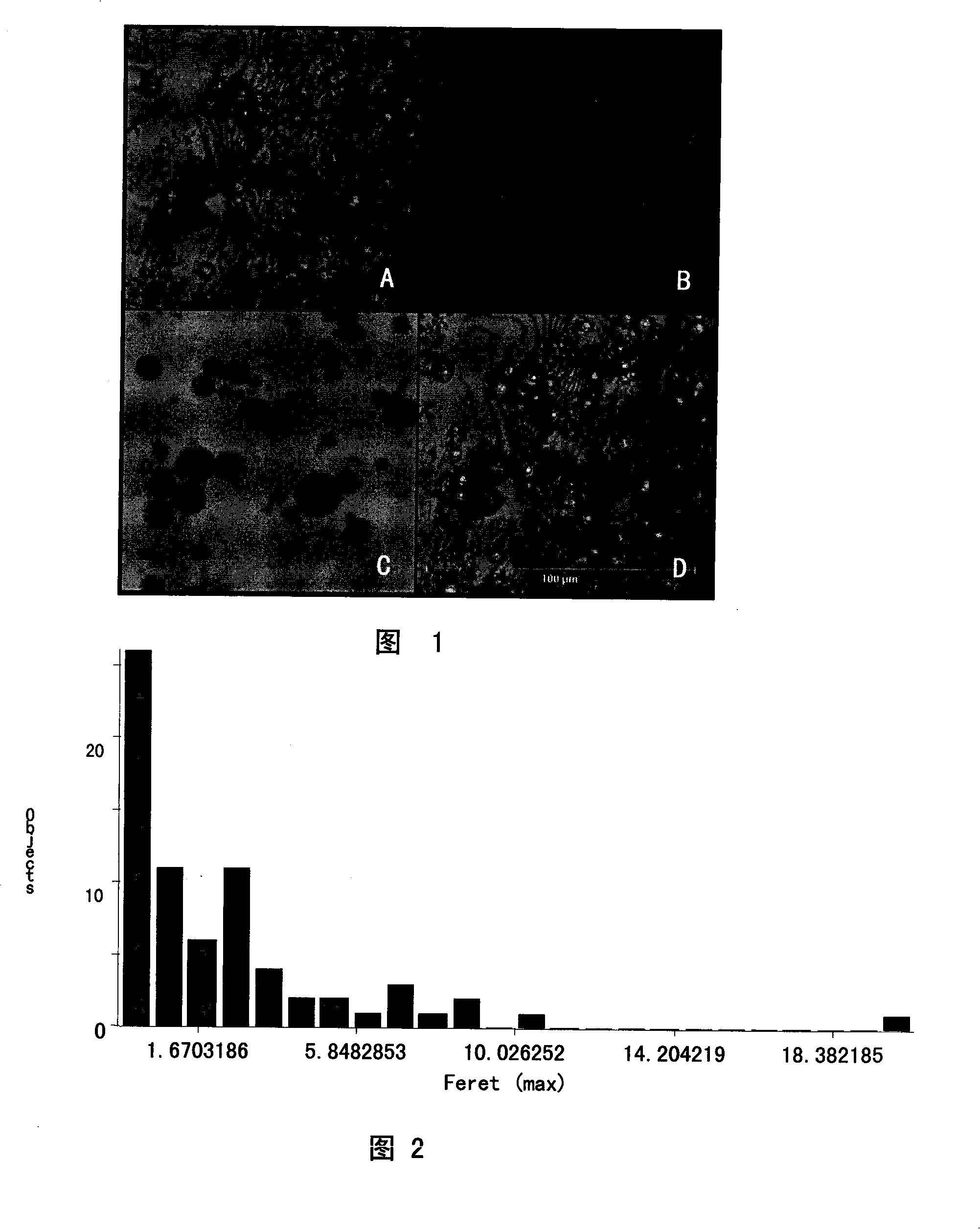

[0035] 2. Use a laser scanning confocal microscope to observe the sample in step 1: select a wavelength of 514nm as the excitation light source, Figure 1 is the observed image reconstructed by software, and part C in Figure 1 is the light emission band 650nm-750nm oil Fluorescence image; part B is the fluorescence image of oil in the luminescence band 550nm-650nm, represented in red; part A is the fluorescence image of water in the luminescence band <550nm, repres...

Embodiment 2

[0049] 1. Take a few drops of relatively stable emulsion and add it to the groove of the slide glass. The size of the slide glass is 7.5×2.5×0.5cm, the radius of the groove circle is 0.75cm, and the depth is 0.25cm. Then cover it with a cover glass. The size of the cover glass is 1.7×1.7cm, and it is sealed with 502 glue, placed in an incubator, and kept at a temperature of 25 degrees for 24 hours. After the temperature is kept constant until the shape of the droplet is regular, it can be observed with a microscope.

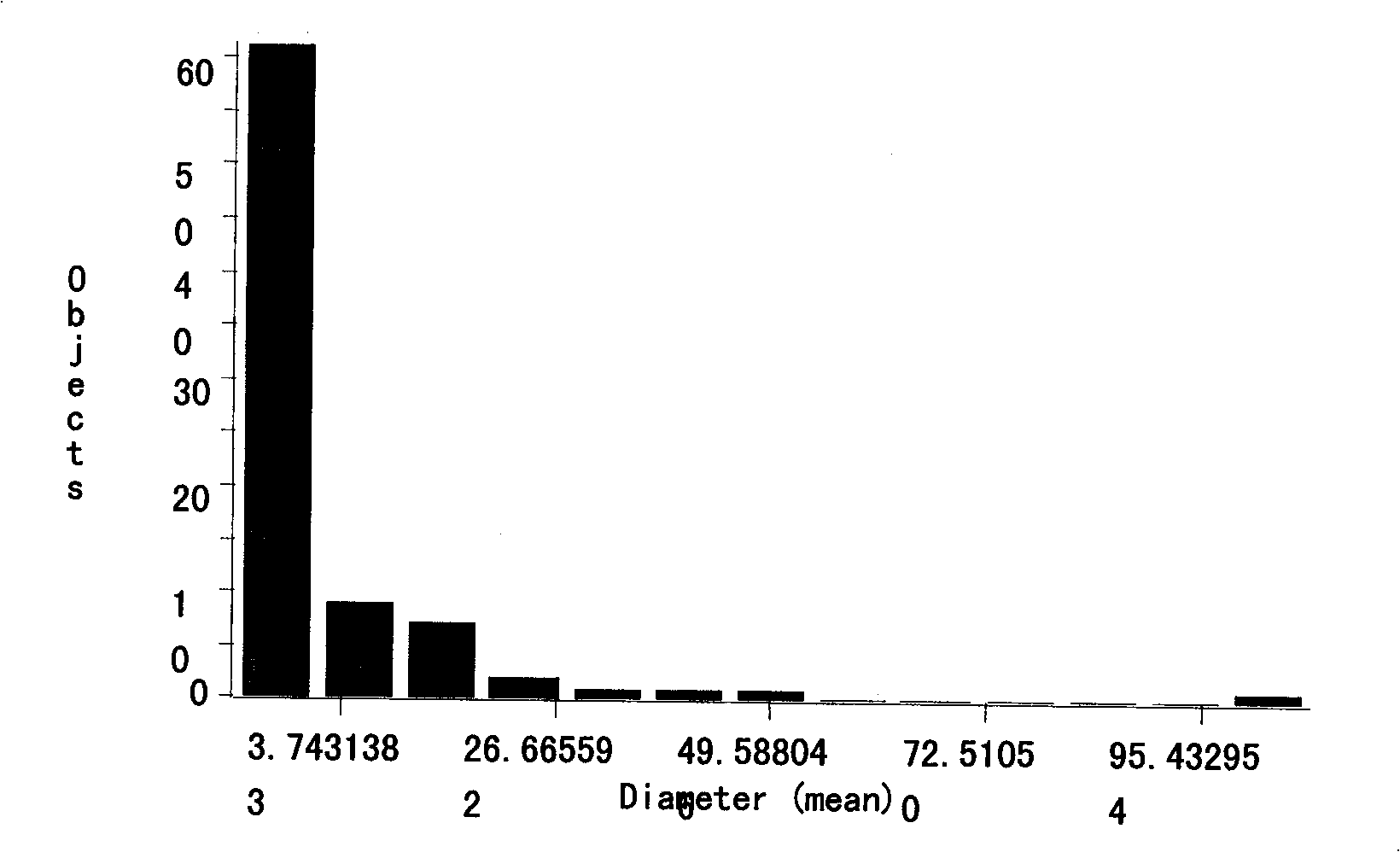

[0050] 2. Observing the sample with a laser scanning confocal microscope: observe the oil, select a laser with a wavelength of 514nm as the excitation light source, and select a wavelength of 550-650nm as the receiving wavelength for observation. To observe the form of water, select the wavelength of 514nm as the excitation light source, and select the wavelength of 400-480nm as the receiving wavelength for observation. Observation Results The images reconstructe...

Embodiment 3

[0064] 1. Take a few drops of relatively stable emulsion and add it to the groove of the slide glass. The size of the slide glass is 7.5×2.5×0.5cm, the radius of the groove circle is 0.75cm, and the depth is 0.25cm. Then cover it with a cover glass. The size of the cover glass is 1.7×1.7cm, and it is sealed with 502 glue, placed in an incubator, and kept at a temperature of 25 degrees for 24 hours. After the temperature is kept constant until the shape of the droplet is regular, it can be observed with a microscope.

[0065] 2. Use a laser scanning confocal microscope to observe the sample: choose a laser with a wavelength of 514nm as the excitation light source. Figure 1 is the observed image reconstructed by software, and part C in Figure 1 is the fluorescence of oil in the luminescence band 650nm-750nm The image is shown in blue; part B is the fluorescence image of oil in the luminescence band 550nm-650nm, which is shown in red; part A is the fluorescence image of water in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com