Malodorous gas processing system and processing method thereof

A technology for treating system and malodorous gas, applied in the direction of separation methods, chemical instruments and methods, chemical/physical/physicochemical processes using energy, etc., can solve the problems of high recombination rate, slow transfer speed, low reaction conversion rate, etc. Achieve high degree of mineralization and better deodorization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

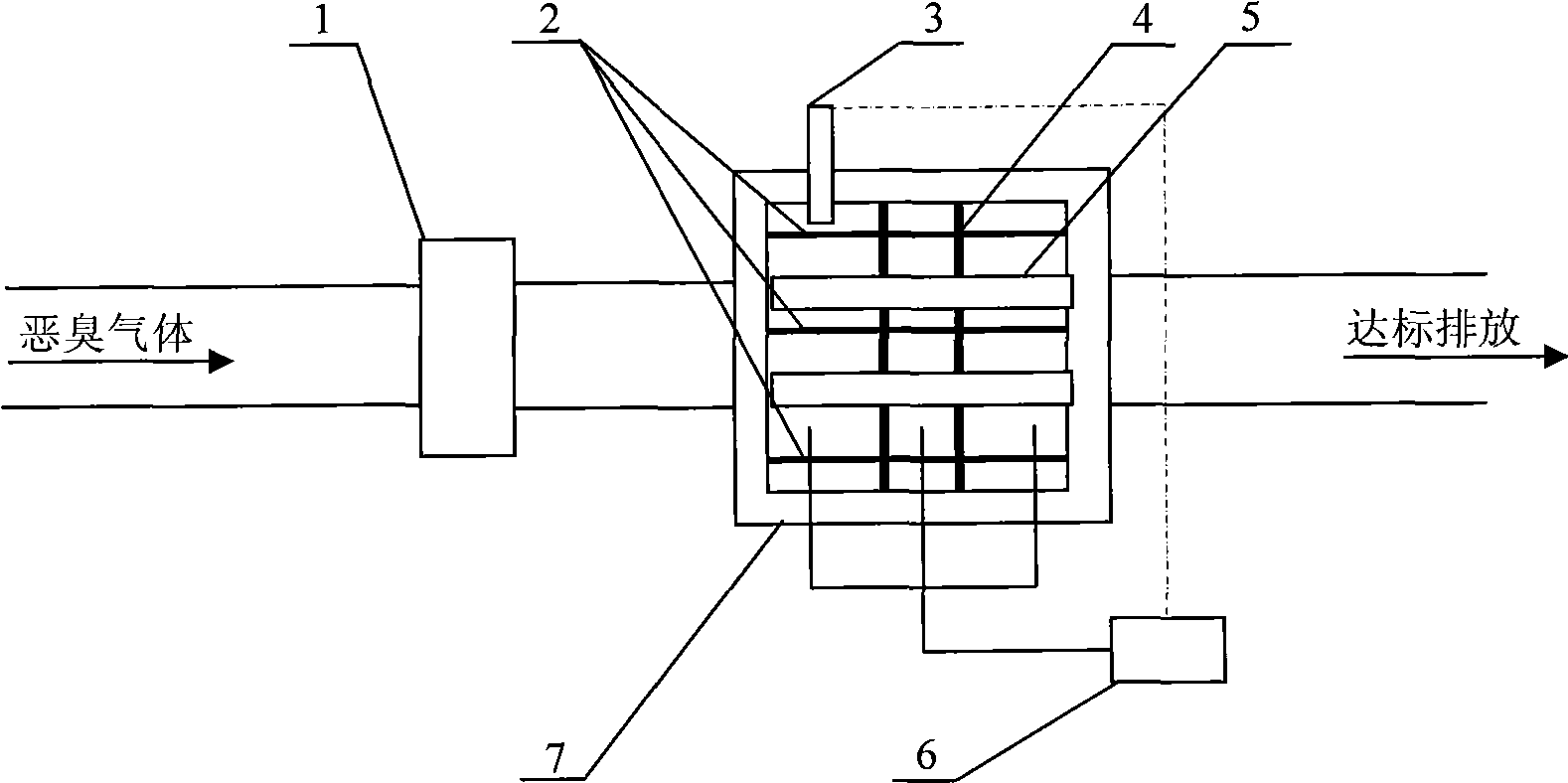

[0016] A treatment system and treatment method for malodorous gas, the adopted technical scheme is divided into treatment system and treatment method, the treatment system is as follows figure 1 As shown: the ultraviolet lamp tube 5 and the rectifying photocatalyst plate 4 are installed in the processing box 7, the ultraviolet lamp tube 5 passes through the rectifying photocatalyst plate 4 vertically, and the inner wall of the processing box 7 and the rectifying photocatalyst plate 4 are evenly coated with nano-scale TiO 2 , activated carbon fiber 2 is placed in the treatment box 7; the humidity sensor 3 is placed in the treatment box 7, the humidifier 6 communicates with the treatment box 7 through a pipeline; the blower fan 1 communicates with the air inlet of the treatment box 7 through an air supply pipe, and the treatment box The air outlet of 7 communicates with atmosphere.

[0017] Wherein, the activated carbon fiber 2 is placed 0.07-0.1 m away from the ultraviolet lamp...

Embodiment 2

[0020] A treatment system and treatment method for malodorous gas, the technical scheme adopted is divided into treatment system and treatment method, the treatment system is as follows figure 1 As shown, except that the activated carbon fiber 2 is placed 0.07-0.1 m away from the ultraviolet lamp 5 and placed in strips parallel to the ultraviolet lamp 5, the others are the same as in the embodiment 1.

[0021] The treatment method of this treatment system is: the relative humidity in the treatment box 7 in the setting treatment system is 70%~90%, the flow velocity of malodorous gas in the treatment box 7 is 0.5~0.8m / s, the ultraviolet light tube 5 The intensity of ultraviolet radiation is 80~100W / m 2 ; The specific surface area of activated carbon fiber 2 is 1300~1600m 2 / g.

[0022] In Embodiments 1 and 2, the blower 1 transports and homogenizes the malodorous gas, controls the inflow of the malodorous gas, and keeps the flow velocity of the malodorous gas within an appro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com