Method for preparing tetrathiafulvalene molecule-based micrometre and/or nano functional material

A tetrathiafulvalene, nano-functional technology, applied in the field of micro- and/or nano-functional materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

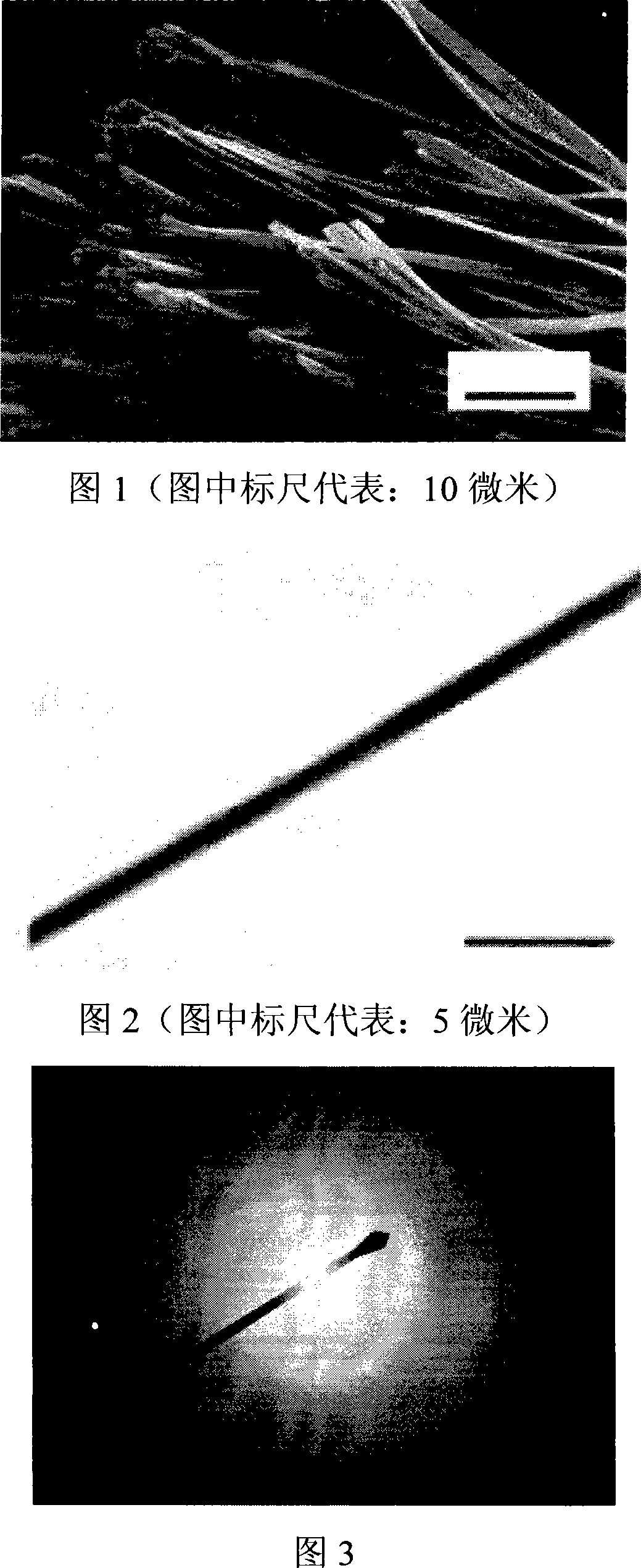

[0057] One of the micron and / or nano functional materials of coordination polymers of tetrathiafulvalene derivatives and metal ions - preparation of organic-inorganic composite semiconductor micron wires:

[0058] At a temperature of 10 degrees Celsius, first 4,4'(5')-bis-(4-pyridylvinyl)-tetrathiafulvalene (mass 8.2 mg) in dichloromethane solution (volume 5 ml) Add in the test tube, then slowly add lead perchlorate (10 mg in mass) in acetonitrile solution (5 ml in volume), because the specific gravity of acetonitrile is less than that of dichloromethane, the two solutions are separated in the test tube. Along with two kinds of solutions permeate and mix each other in the test tube, 4,4'(5')-bis-(4-pyridylvinyl)-tetrathiafulvalene and lead perchlorate react (molar ratio 1:1), A purple solid was obtained in the test tube after two weeks. SEM images (see figure 1 ) and TEM images (see figure 2 ) indicates that the purple solid is a micron wire, the diameter of the micron wir...

Embodiment 2

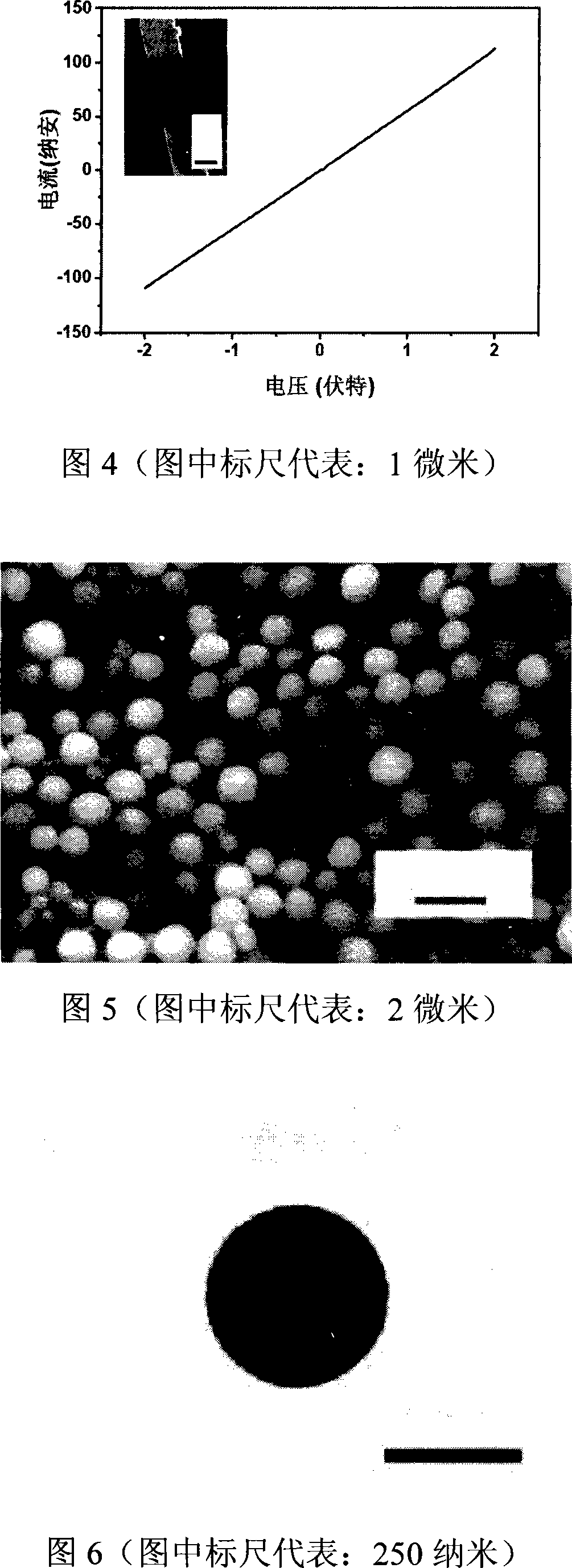

[0061] Preparation of micron and / or nano functional materials of coordination polymers of tetrathiafulvalene derivatives and metal ions-organic-inorganic composite nanospheres:

[0062] At a temperature of 8 degrees Celsius, first 4,4'(5')-bis-(4-pyridylvinyl)-tetrathiafulvalene (mass 8.2 mg) in dichloromethane solution (volume 5 ml) Add in the test tube, then slowly add zinc perchlorate (8 mg in mass) in acetonitrile solution (5 ml in volume), because the specific gravity of acetonitrile is less than that of dichloromethane, the two solutions are separated in the test tube. Along with two kinds of solutions permeate and mix each other in the test tube, 4,4'(5')-bis-(4-pyridylvinyl)-tetrathiafulvalene and zinc perchlorate react (molar ratio 1:1), After two weeks a purple solid was obtained in the test tube. SEM images (see Figure 5 ) and TEM images (see Figure 6 ) shows that the purple-red solid is a nanosphere, the diameter of the nanosphere is about 250 nanometers, and ...

Embodiment 3

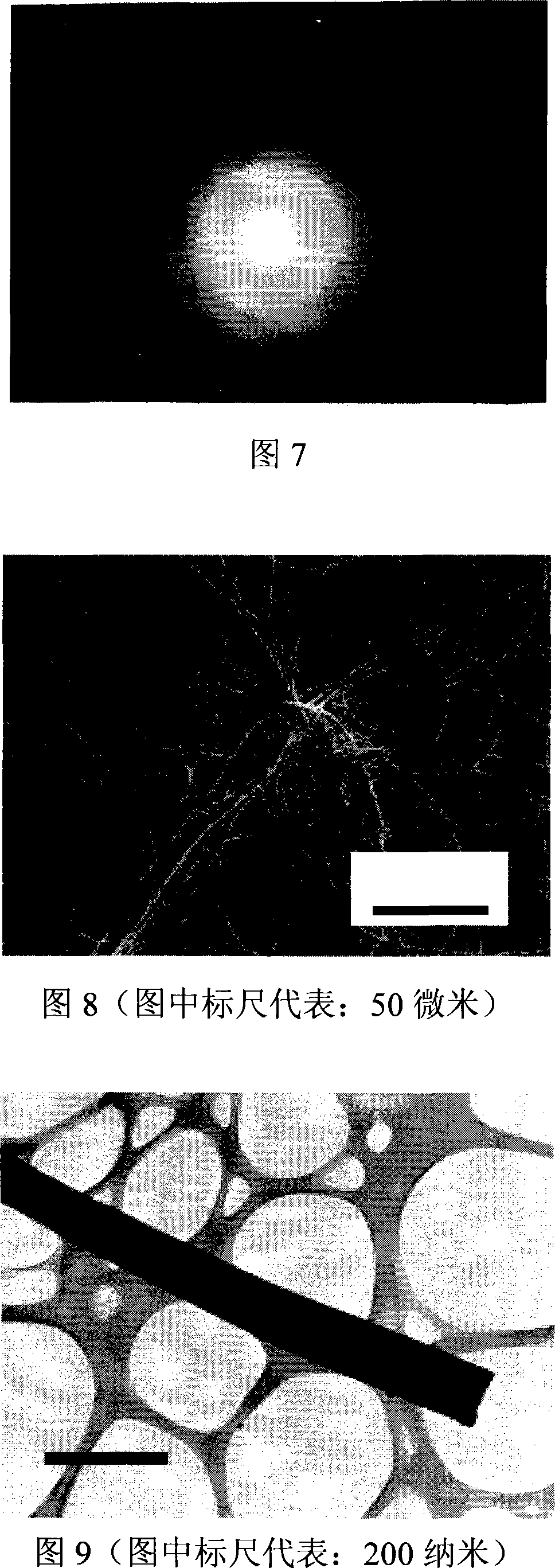

[0064] Micron and / or nano functional materials of coordination polymers of tetrathiafulvalene derivatives and metal ions 3- Preparation of organic-inorganic composite nanowires:

[0065] At a temperature of 5 degrees Celsius, the clean silicon wafer was immersed in the compound 4,4'(5')-bis-(4-pyridylvinyl)-tetrathiafulvalene and lead perchlorate at a molar ratio of 1:1. Acetone solution (concentration is about 1×10 -4 Mole per liter, volume is 10 milliliters), in the container that above-mentioned solution and silicon chip place are placed openly. Three days later, the acetone solvent in the container was completely volatilized, and the silicon wafer was taken out, and a large number of nanowires were formed on the surface of the silicon wafer as observed through a scanning electron microscope. SEM images (see Figure 8 ) and TEM images (see Figure 9 ) show that the maximum length of the nanowires reaches several hundreds of micrometers, and the diameter is 80 to 150 nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com