Preparation of core type greening brick

A green brick and core technology, applied in chemical instruments and methods, clay preparation devices, manufacturing tools, etc., can solve the problems of short effective time, high cost, slow growth rate of plants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

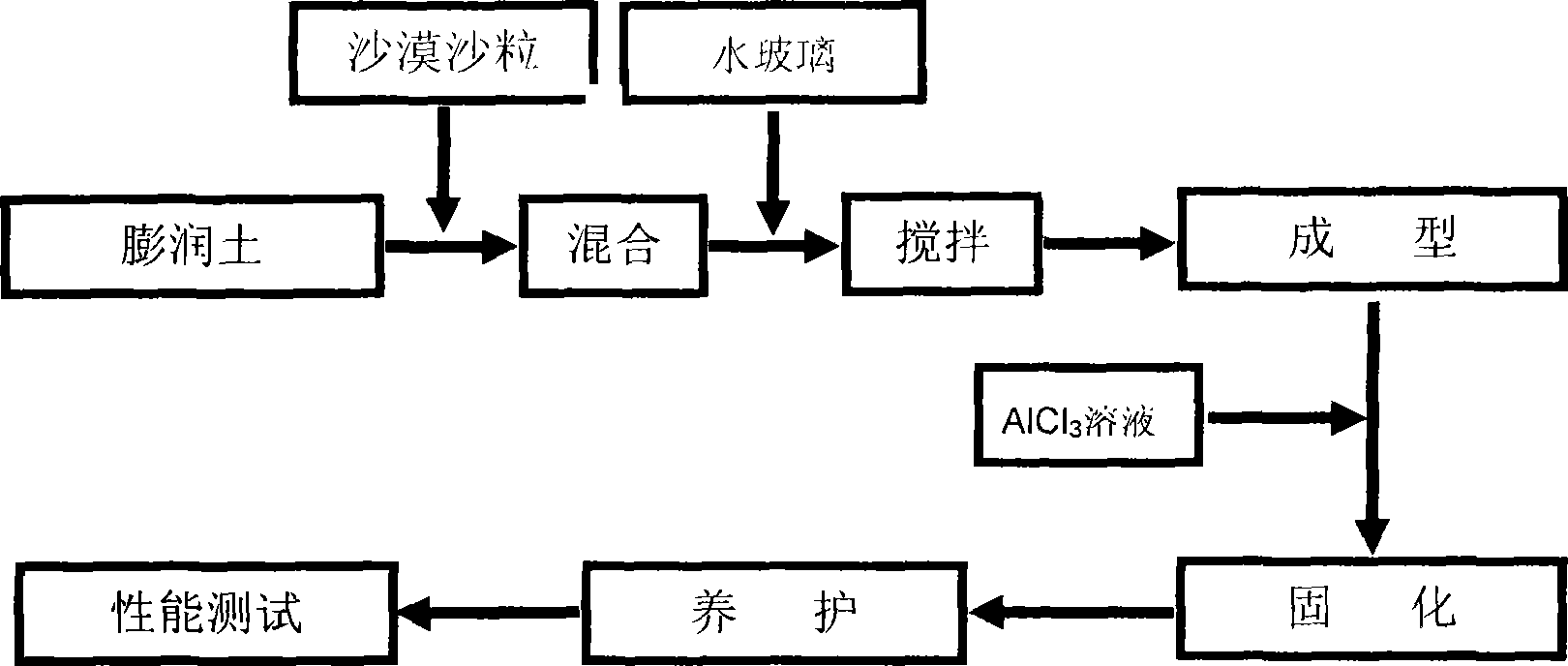

Method used

Image

Examples

Embodiment 1

[0045] Preparation of desert green bricks under normal temperature conditions:

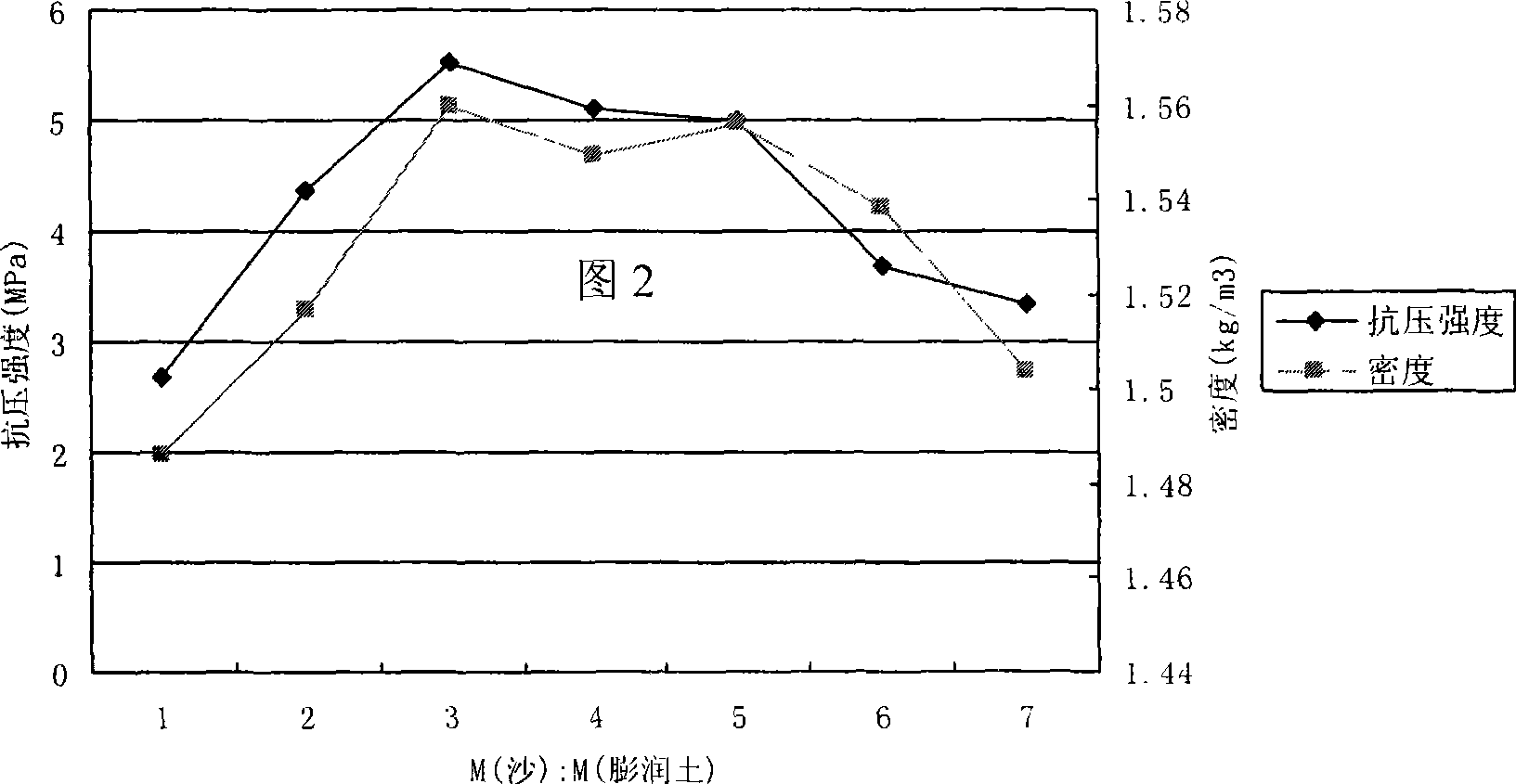

[0046] (1) Weigh 12kg of the mixture of sand and bentonite (the ratio is M sand: M bentonite = 3:1), 1200ml of water glass, and mix well.

[0047] (2) Put the mixture into the QJ4-35 porous forming mold, vibrate while putting it down, until the mixture is full, pull down the pressure head, vibrate up and down twice, and lift the pressure head to demould.

[0048] (3) Take out the molded brick, spray its surface with 0.2mol / L curing agent, and put it into AlCl with a curing concentration of 3mol / L when it can be lifted by hand 3 Soak in the solution for 5 minutes, and take out the sand bricks after curing for 7 days at room temperature.

Embodiment 2

[0050] Preparation of desert green bricks under normal temperature conditions:

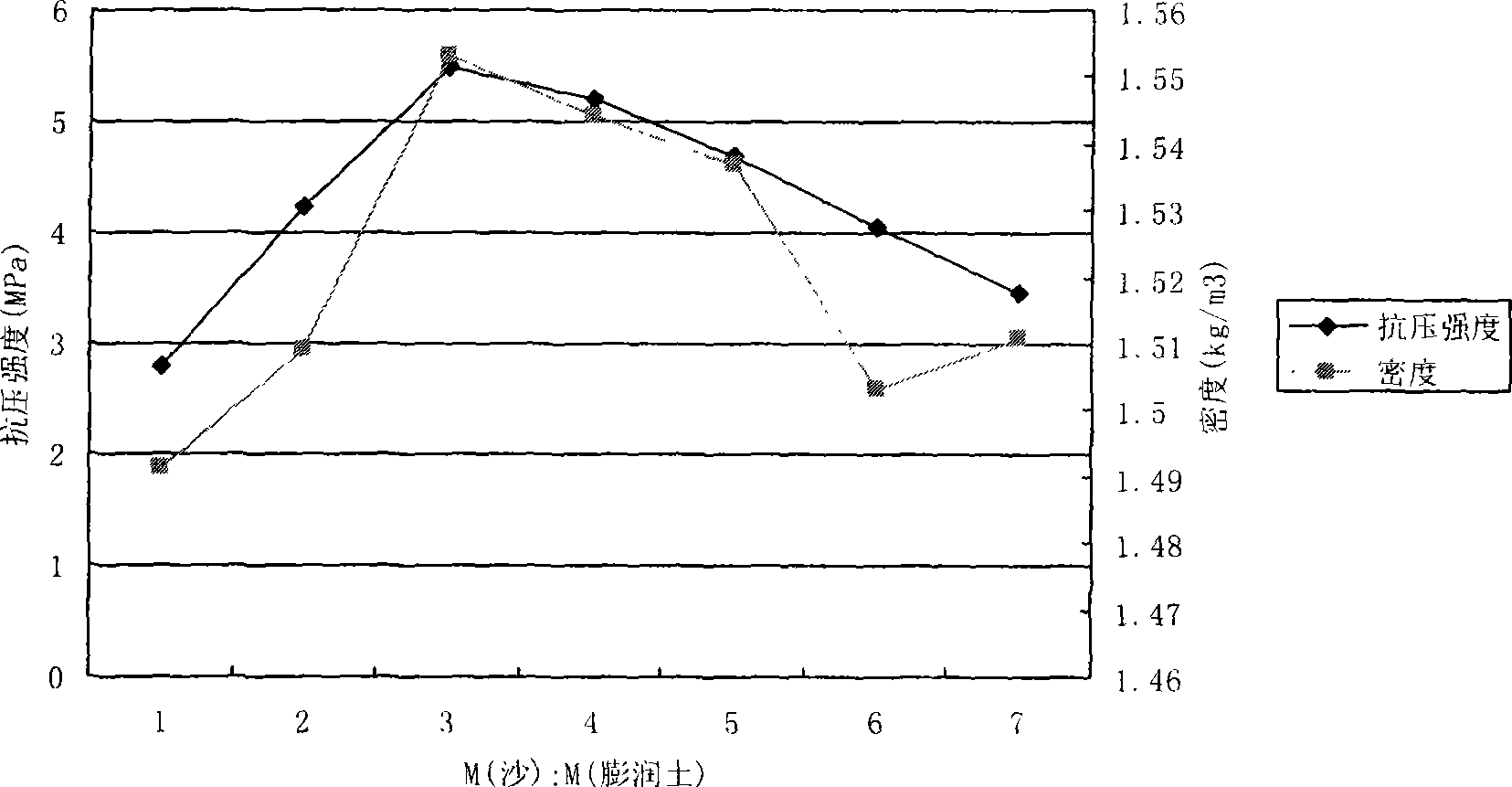

[0051] (1) Weigh 15kg of desert sand, mix with 4kg of bentonite, then add gelling agent (1500ml of water glass), and fully mix;

[0052] (2) Put the mixture into the mold, vibrate while placing it, until the mixture is full, pull down the pressure head, vibrate up and down twice, and lift the pressure head to demould;

[0053] (3) Take out the molded brick, spray its surface with 200ml of curing agent, and put it into AlCl with a curing concentration of 3mol / L when it can be lifted by hand 3 Soak in the solution for 10 minutes, and take out the sand bricks for curing for 7 days after curing.

Embodiment 3

[0055] (1) Weigh 9kg of desert sand, mix 3kg of bentonite, add gelling agent (1.6kg of water glass), and mix thoroughly;

[0056] (2) Put the mixture into the mold, vibrate while placing it, until the mixture is full, pull down the pressure head, vibrate up and down twice, and lift the pressure head to demould;

[0057] (3) Take out the molded brick, spray its surface with 200ml of curing agent, put it into the curing concentration of aluminum chloride solution 8kg AlCl when it can be lifted by hand 3 Soak in the solution for 10 minutes, and take out the sand bricks for curing for 7 days after curing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com