Horizontal axle wind mill with blade tip winglet

A wind turbine and horizontal axis technology, which is applied in the field of wind power generation equipment, can solve the problems of complex structure, high manufacturing cost, and high processing difficulty of wind rotor blade tip winglets, and achieves improved structural dynamic characteristics, low manufacturing cost, and comprehensive improvement. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

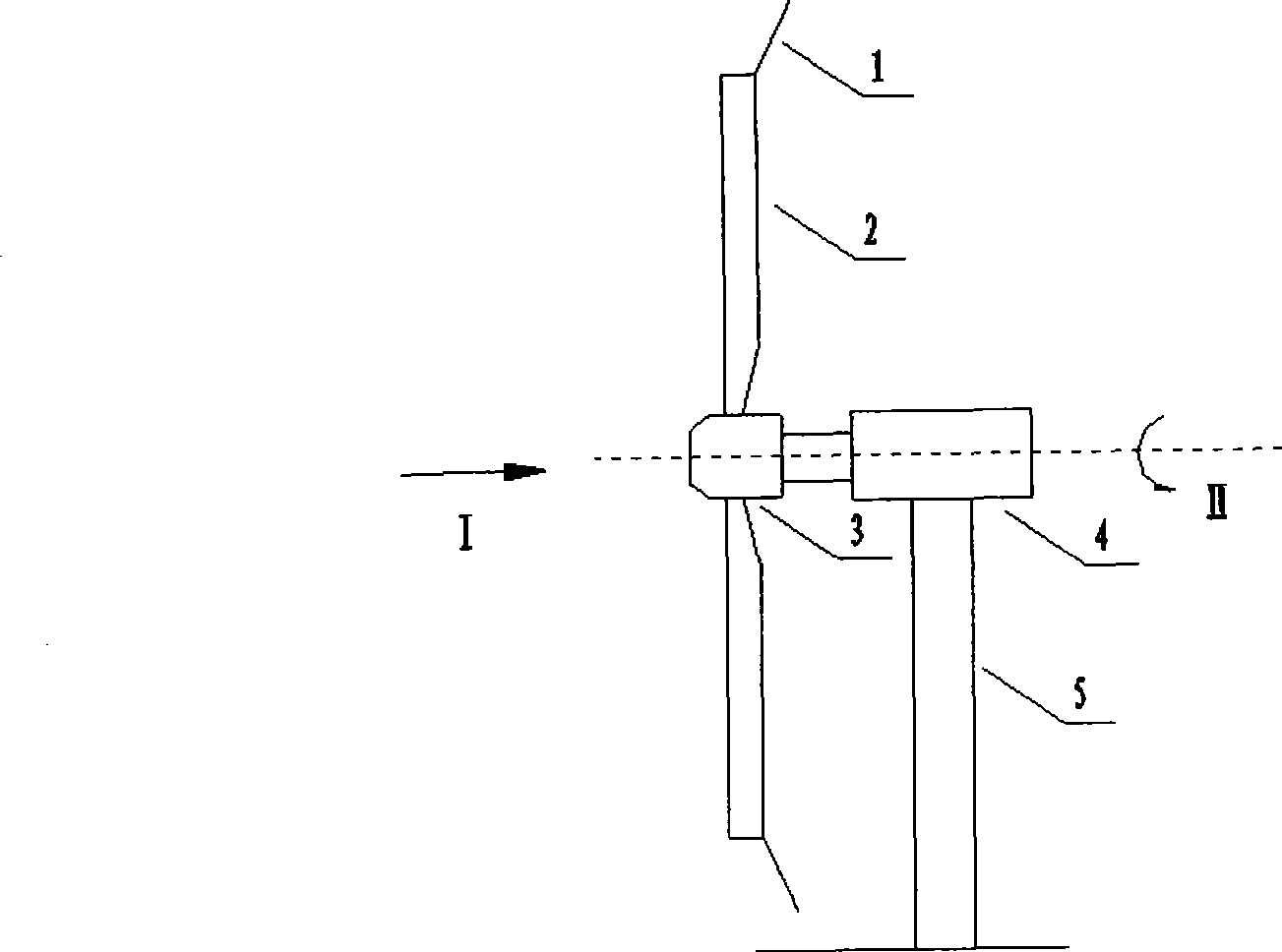

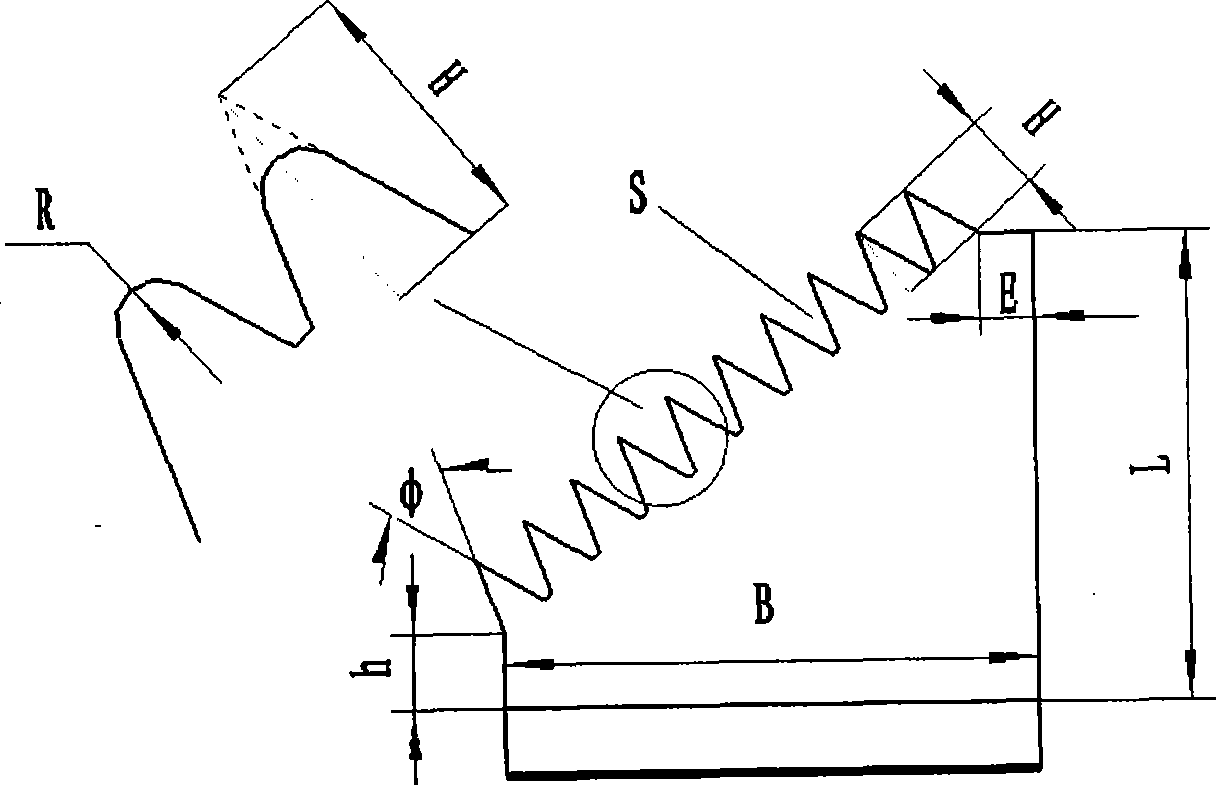

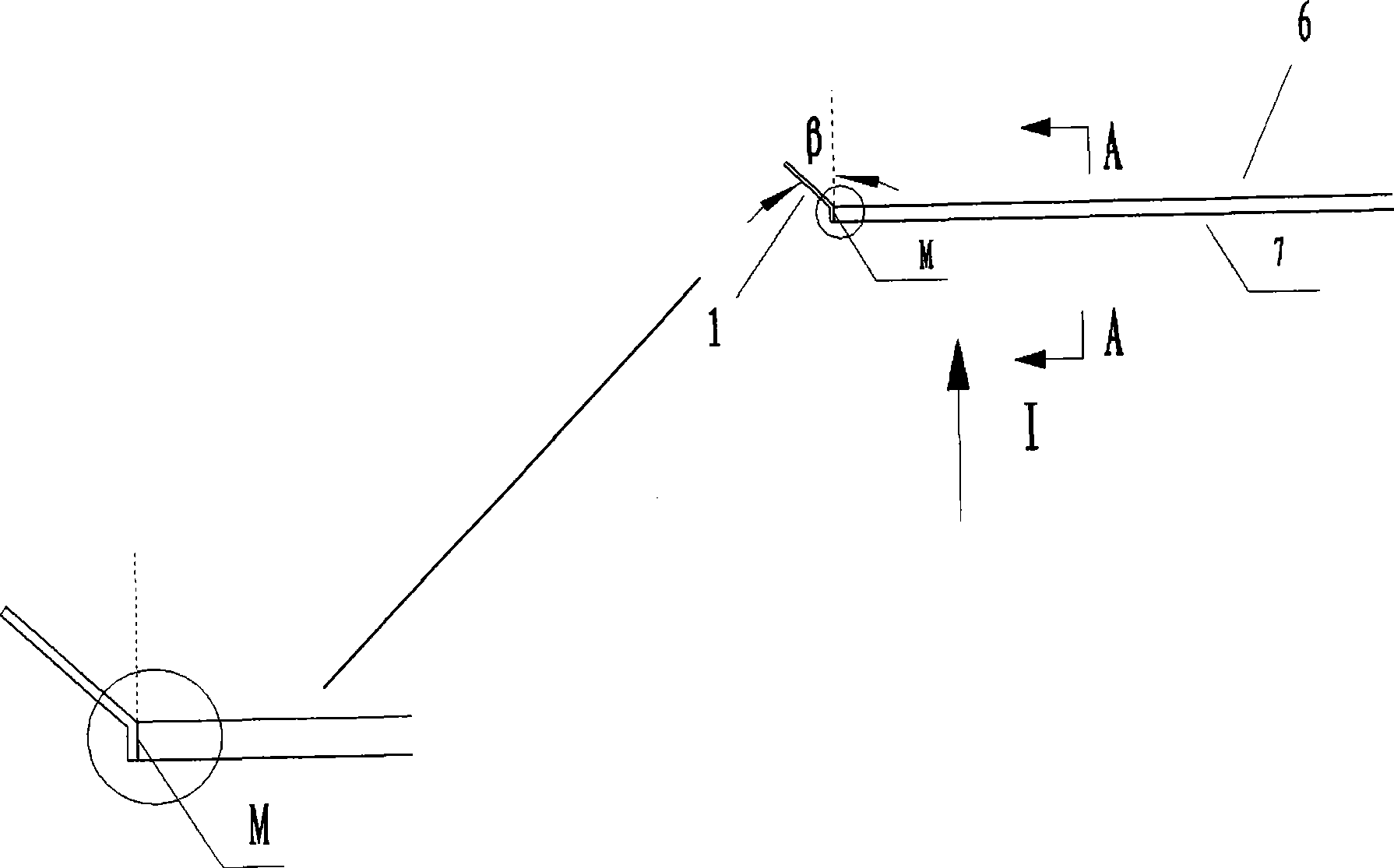

[0012] Below in conjunction with accompanying drawing and embodiment the technical scheme of the present invention will be further described

[0013] attached Figure 1~4 The labels in the figure represent respectively: 1-tooth winglet, 2-wind turbine blade, 3-hub, 4-nacelle, 5-tower, 6-blade suction surface, 7-blade pressure surface, I-flow direction, II-wind turbine rotation direction, B-mounting surface folded edge, L-straight edge of leading edge, h-straight edge of trailing edge, E-connecting edge, H-tooth height, φ-vertex angle of hypotenuse of tooth profile, S- Tooth type hypotenuse, R-tooth tip arc radius, M-installation surface, I-incoming flow direction, B-installation surface folded edge, L-straight edge of front edge h-straight edge of rear edge, E-connection edge, H-tooth height, φ-tooth tip angle, a-airfoil leading edge point, b-airfoil trailing edge point, c-blade tip airfoil chord line, β-back tension angle.

[0014] Overall structure of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com