Hydrogen generating apparatus and fuel cell system

A generation device and combustion gas technology, applied in fuel cells, hydrogen/synthesis gas production, hydrogen, etc., can solve problems such as insufficient removal of carbon monoxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

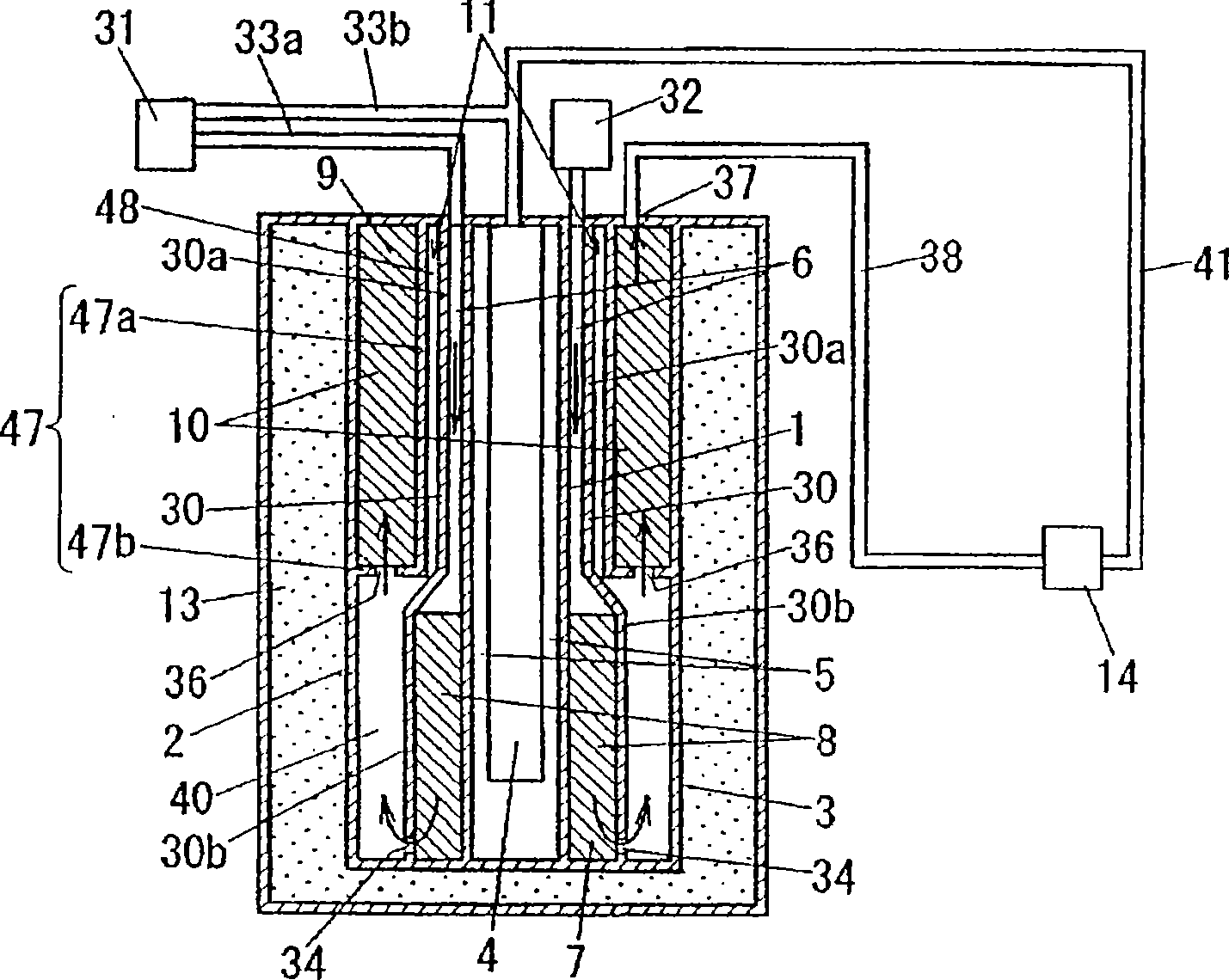

[0081] figure 1 It is a cross-sectional view schematically showing the configuration of the hydrogen generator and the fuel cell system according to Embodiment 1 of the present invention. Such as figure 1 As shown, in this embodiment, the cylindrical body 3 serving as the frame of the device is formed by arranging the cylindrical inner cylinder (partition wall) 1 and the outer cylinder (partition wall) 2 in a concentric two-layer cylindrical shape with the axial direction as the longitudinal direction. And formed. The upper and lower ends of the cylindrical body 3 are closed. A burner 4 constituted by a burner is provided at the center of the inner circumference of the inner cylinder 1 , and a combustion gas passage 5 is formed between the burner 4 and the inner cylinder 1 along the inner circumference of the inner cylinder 1 . The combustion gas passage 5 communicates with the outside (atmosphere) through an outlet (not shown).

[0082]Between the inner cylinder 1 and t...

Embodiment approach 2

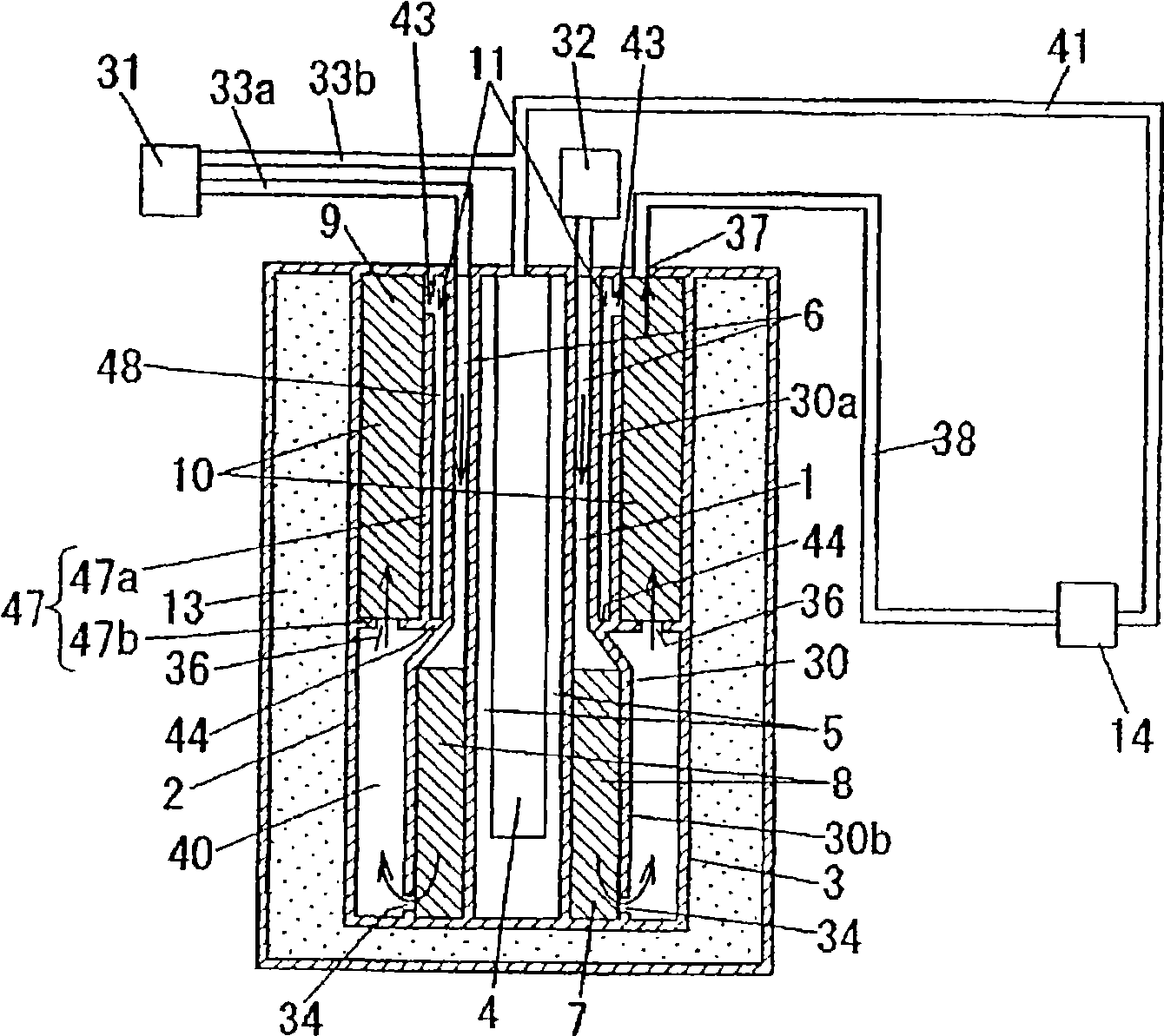

[0101] figure 2 It is a cross-sectional view schematically showing the configuration of a hydrogen generator and a fuel cell system according to Embodiment 2 of the present invention. Such as figure 2 As shown, in this embodiment, the lower end of the heat transfer buffer space 48 is blocked with the cover plate 44 to prevent it from communicating with the reformed gas circulation path 40, and at the same time, the isolation of the inner periphery of the carbon monoxide reducer 10 is defined. The communication port 43 is provided in the upper part of the vertical wall 47a of the wall 47, and is provided so that the heat transfer buffer space 48 may communicate with the carbon monoxide reducer 10. As for other components and figure 1 means the same.

[0102] In this configuration, since the heat transfer buffer space 48 and the carbon monoxide reducer 10 are communicated through the communication port 43 , low CO concentration reformed gas from which carbon monoxide has b...

Embodiment approach 3

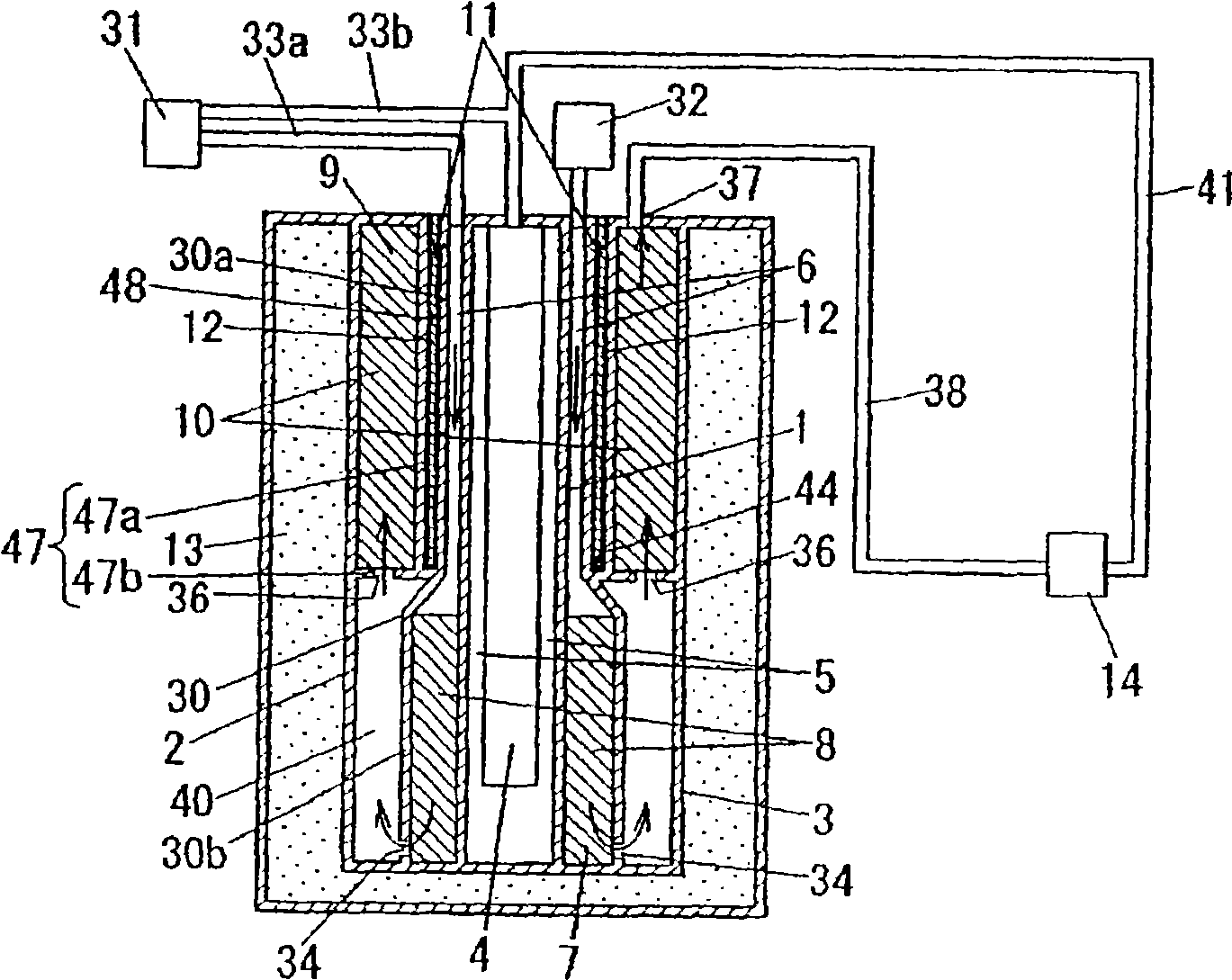

[0104] image 3 It is a cross-sectional view schematically showing the configuration of a hydrogen generator and a fuel cell system according to Embodiment 3 of the present invention. Such as image 3 As shown, in this embodiment, the lower end of the heat transfer buffer space 48 is blocked with the cover plate 44 so as not to communicate with the reformed gas circulation path 40, and at the same time, the upper end of the heat transfer buffer space 48 is defined The upper wall of the body 3 is opened so as to communicate with the outside of the cylinder body 3 . Therefore, the heat transfer buffer space 48 is isolated from the inside of the barrel 3 . In addition, the heat transfer buffer space 48 is filled with the heat transfer member 12 . The thermally conductive member 12 is made of, for example, an appropriately selected metal having good thermal conductivity. As for the other components are the same as figure 1 means the same.

[0105] In the present embodiment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com