Method for preparing pH-sensitive photocrosslinkable hydrogel

A technology of cross-linked hydrogel and photo-cross-linking agent, which is applied in the field of preparation of pH-sensitive photo-cross-linked hydrogel, can solve the problem that glutaraldehyde and carboxymethyl chitosan aqueous solution are difficult to mix uniformly and gel Weak pH sensitivity or even no problems, to achieve the effect of being suitable for industrial production, convenient dosage form molding, and increasing water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

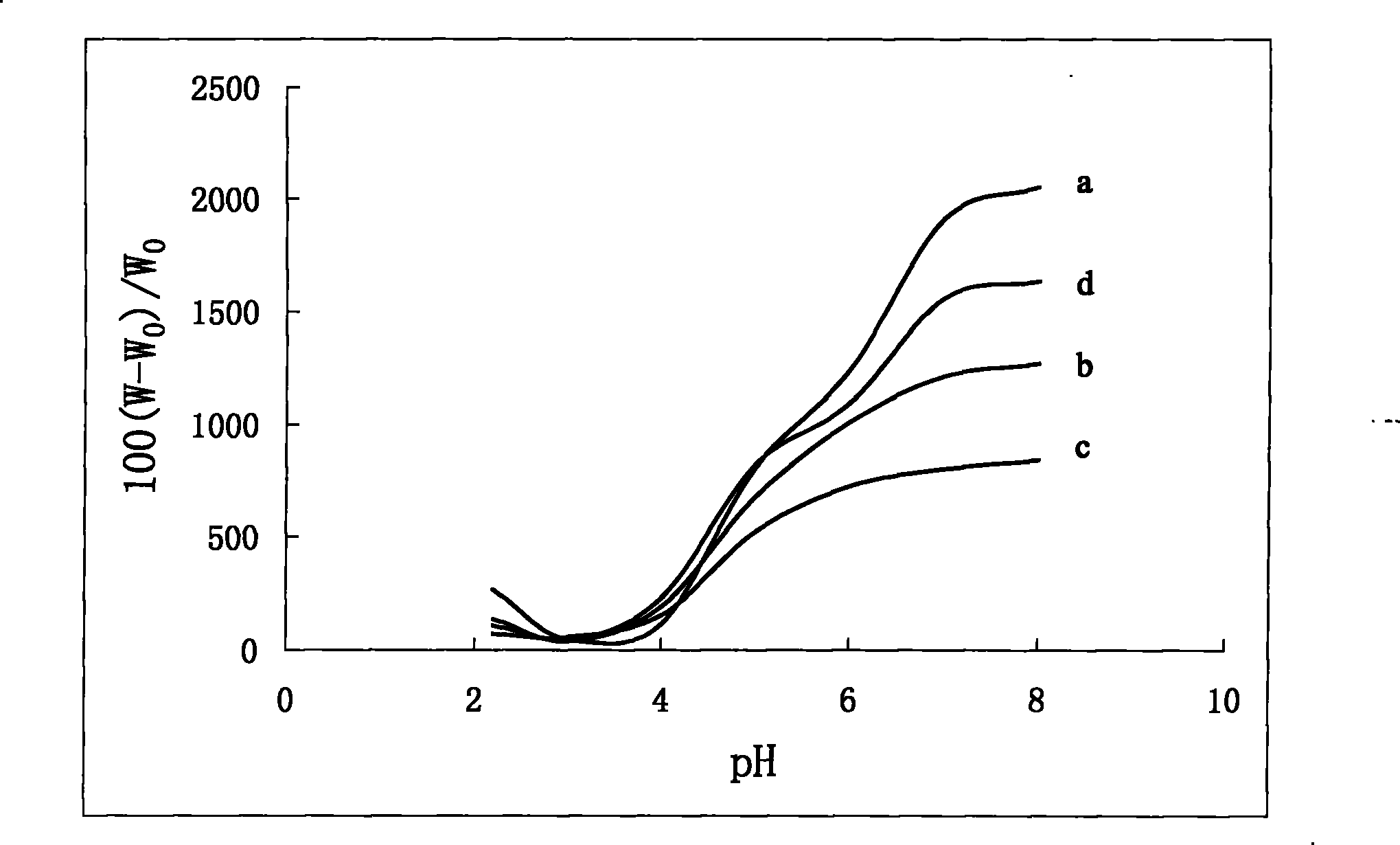

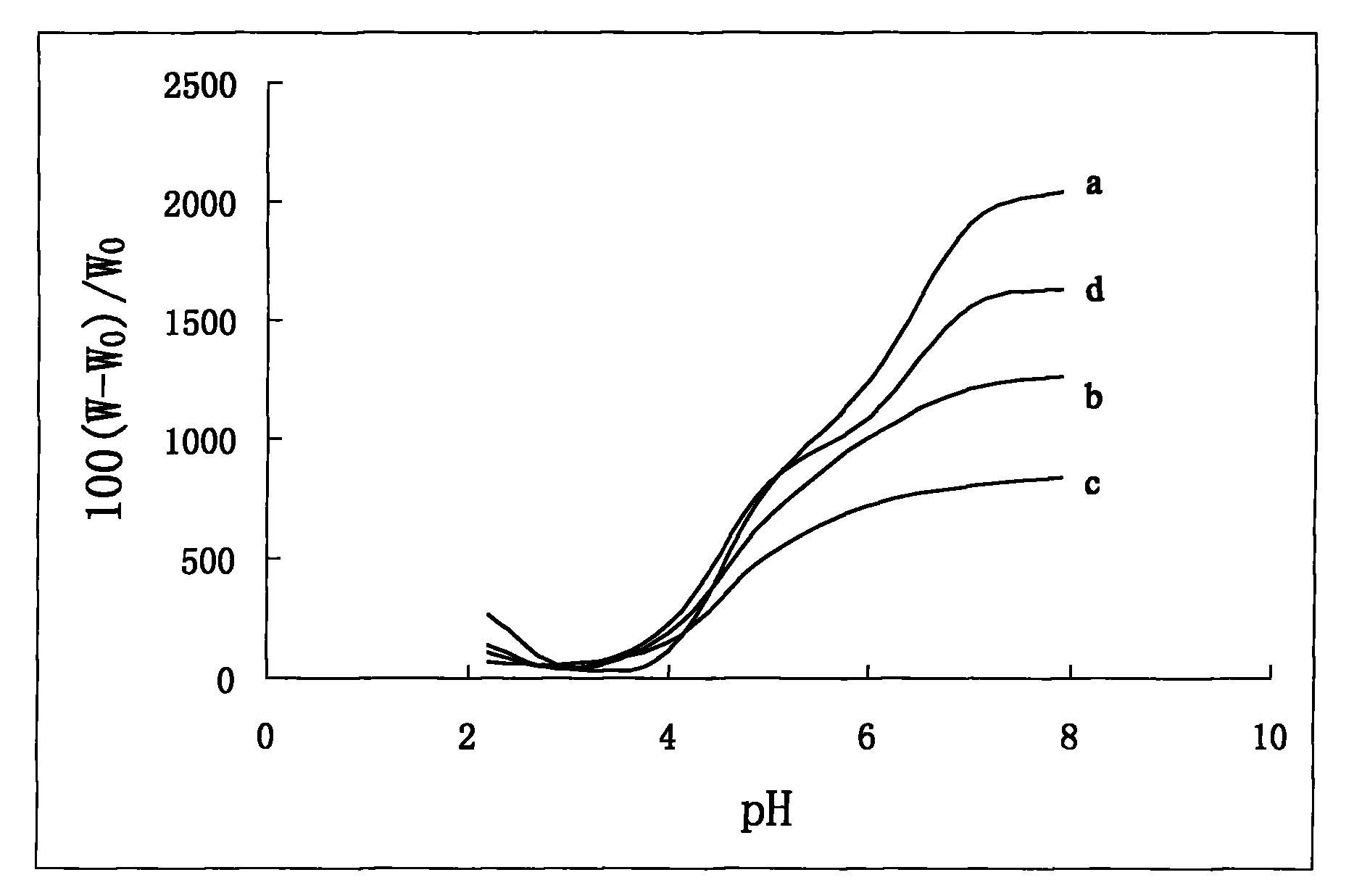

Embodiment 1

[0021] Dissolve 0.4 g of the synthesized 4-azidobenzaldehyde in 0.1 g of absolute ethanol to prepare a photocrosslinking agent solution with a weight concentration of 80%, and store it away from light. The carboxymethyl substitution degree is 0.8, the viscosity average molecular weight is 5.5×10 5 Add 0.15 g of carboxymethyl chitosan into 15 g of distilled water, stir at room temperature until completely dissolved, and obtain a carboxymethyl chitosan aqueous solution with a weight concentration of 1%. Under the condition of protecting from light, 0.03 g of the above-mentioned photocrosslinking agent solution was added dropwise to the obtained carboxymethyl chitosan aqueous solution, and then the temperature was controlled at 25° C. and the reaction was stirred in the dark to make it completely mixed evenly. After vacuum degassing, spread the reaction solution on a glass plate, and irradiate with ultraviolet light (20w, 253.7nm) to form a pH-sensitive hydrogel.

Embodiment 2

[0023] Dissolve 0.4 g of the synthesized 4-azidobenzaldehyde in 0.1 g of absolute ethanol to prepare a photocrosslinking agent solution with a weight concentration of 80%, and store it away from light. The carboxymethyl substitution degree is 1.0, the viscosity average molecular weight is 5.5×10 5 Add 0.15 g of carboxymethyl chitosan into 7.5 g of distilled water, stir at room temperature until completely dissolved, and obtain a carboxymethyl chitosan aqueous solution with a weight concentration of 2%. Under the condition of protecting from light, 0.03 g of the above-mentioned photocrosslinking agent solution was added dropwise to the obtained carboxymethyl chitosan aqueous solution, and then the temperature was controlled at 25° C. and the reaction was stirred in the dark to make it completely mixed evenly. After vacuum degassing, spread the reaction solution on a glass plate, and irradiate with ultraviolet light (20w, 253.7nm) to form a pH-sensitive hydrogel.

Embodiment 3

[0025] Dissolve 0.4 g of the synthesized 4-azidobenzaldehyde in 0.1 g of absolute ethanol to prepare a photocrosslinking agent solution with a weight concentration of 80%, and store it away from light. The carboxymethyl substitution degree is 1.2, the viscosity average molecular weight is 5.5×10 5 Add 0.15 g of carboxymethyl chitosan into 5 g of distilled water, stir at room temperature until completely dissolved, and obtain a carboxymethyl chitosan aqueous solution with a weight concentration of 3%. Under the condition of protecting from light, 0.03 g of the above-mentioned photocrosslinking agent solution was added dropwise to the obtained carboxymethyl chitosan aqueous solution, and then the temperature was controlled at 25° C. and the reaction was stirred in the dark to make it completely mixed evenly. After vacuum degassing, spread the reaction solution on a glass plate, and irradiate with ultraviolet light (20w, 253.7nm) to form a pH-sensitive hydrogel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com