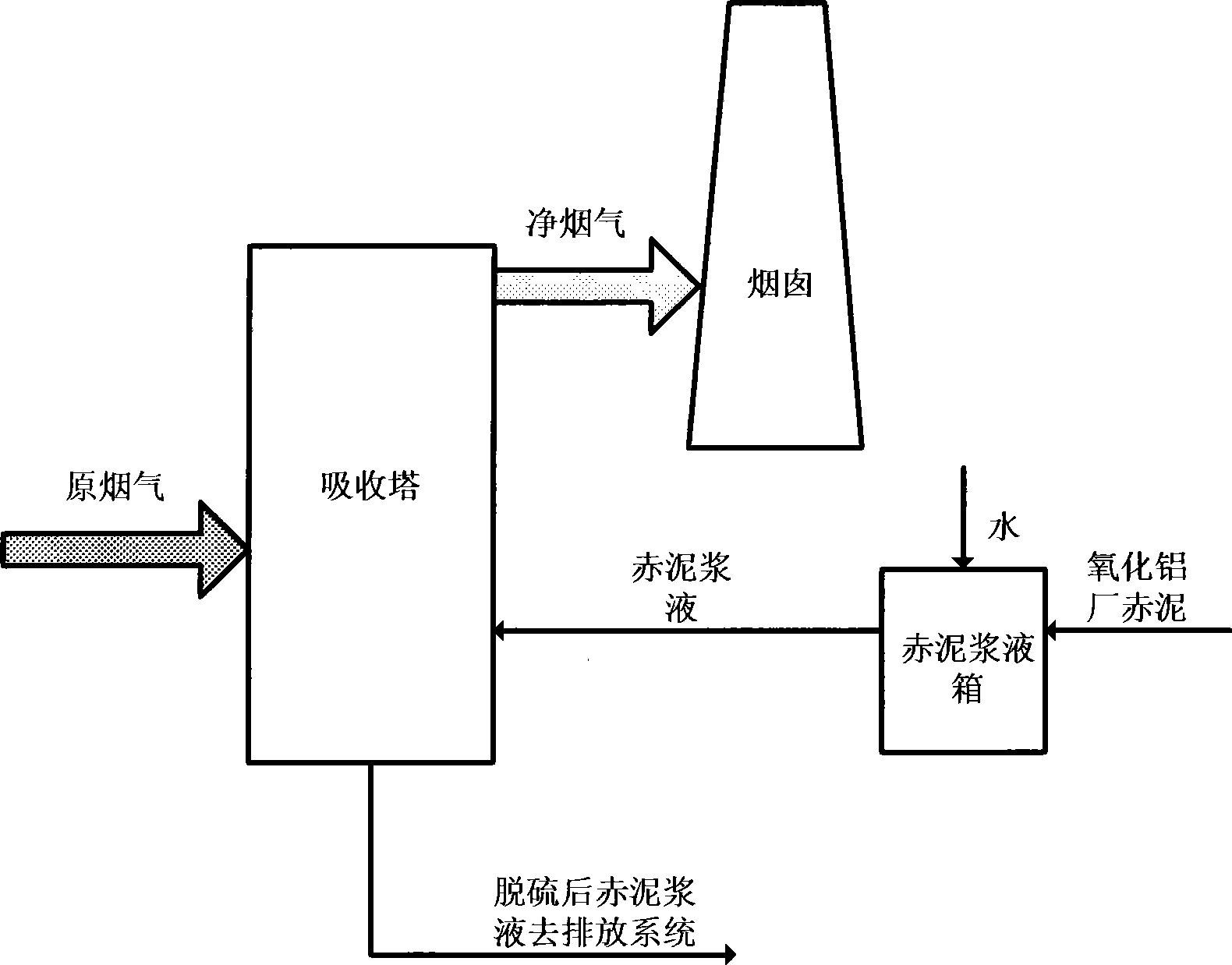

Method for removing acid gases in flue gas using red mud as absorbing agent

A technology of acidic gas and absorbent, applied in separation methods, chemical instruments and methods, separation of dispersed particles, etc., can solve problems such as increased power consumption, system outage, large pressure drop, etc., to improve utilization rate, operation and maintenance amount The effect of small size and simple system setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Adjust the liquid solid content of the red mud slurry entering the absorption tower to 13%. The form of the absorption tower is a spray tower. In the spray tower, under the action of the circulation pump, the absorption slurry is sprayed in a mist form out, fully countercurrent contact with the flue gas entering from the middle of the tower to absorb the SO 2 , Control the pH value of the absorption slurry to 6.0. The desulfurized flue gas is discharged into the chimney after the fine liquid droplets are removed by the demister, and the by-product red mud after desulfurization is pumped out of the absorption system. The flue gas volume at the entrance of the absorption tower is 790980Nm 3 / h, SO 2 The content is 4387mg / Nm 3 , the export content is 573mg / Nm 3 , desulfurization efficiency 86.9%, desulfurization system inlet SO 2 The flow rate is 3.47t / h, and the red mud consumption is 362.9t / h.

Embodiment 2

[0042] Adjust the liquid-solid content of the red mud slurry entering the absorption tower to 25%. The form of the absorption tower is a spray tower. out, fully countercurrent contact with the flue gas entering from the middle of the tower to absorb the SO 2 , control the pH value of the absorption slurry to 7.0. The desulfurized flue gas is discharged into the chimney after the fine liquid droplets are removed by the demister, and the by-product red mud after desulfurization is pumped out of the absorption system. The flue gas volume at the entrance of the absorption tower is 823861Nm 3 / h, SO 2 The content is 4622mg / Nm 3 , the export content is 413mg / Nm 3 , the desulfurization efficiency is 91.1%, and the inlet SO of the desulfurization system 2 The flow rate is 3.81t / h, and the red mud consumption is 310.2t / h.

Embodiment 3

[0044] Adjust the liquid solid content of the red mud slurry entering the absorption tower to 18%. The form of the absorption tower is a bubble tower. In the bubble tower, under the action of a booster fan, the flue gas enters the red mud slurry from the injection pipe to form a bubble layer. , in the bubbling layer, the red mud slurry is in full countercurrent contact with the flue gas to absorb the SO 2 , Control the pH value of the absorption slurry to 5.5. The desulfurized flue gas is discharged into the chimney after the fine liquid droplets are removed by the demister, and the by-product red mud after desulfurization is pumped out of the absorption system. The flue gas volume at the entrance of the absorption tower is 803421Nm 3 / h,SO 2 The content is 5120mg / Nm 3 , the export content is 389mg / Nm 3 , the desulfurization efficiency is 92.4%, and the inlet SO of the desulfurization system 2 The flow rate is 4.11t / h, and the red mud consumption is 510.2t / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com