Milling cutter for high speed machining of non-metallic material

A technology of non-metallic materials and milling cutters, which is applied in the direction of milling cutters, metal processing equipment, manufacturing tools, etc., can solve the problem of not being able to meet the requirements of high-speed and high-precision processing of non-metallic materials, the influence of the surface quality and dimensional accuracy of the processing object, and the cutting edge Parts are easy to be stuffed and other problems, so as to achieve the effect of light cutter body, smooth chip removal and smooth chip discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

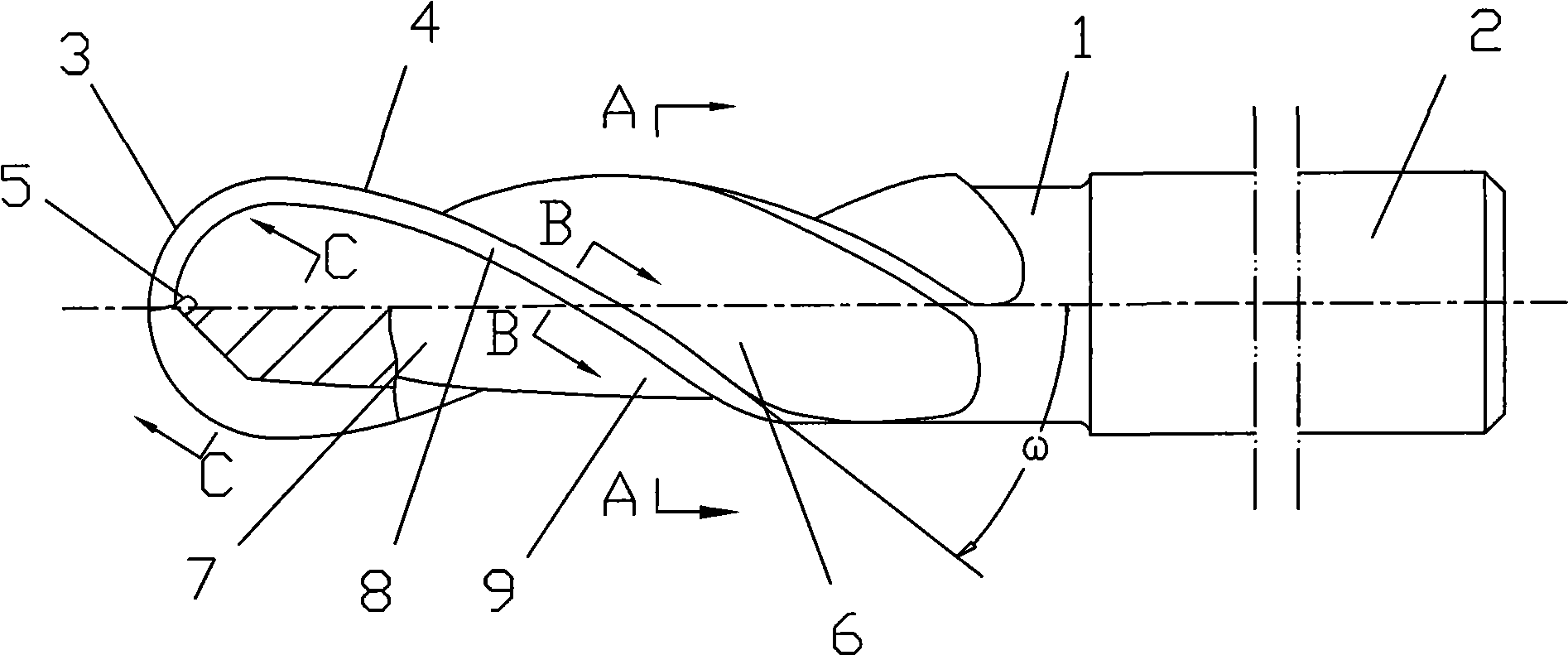

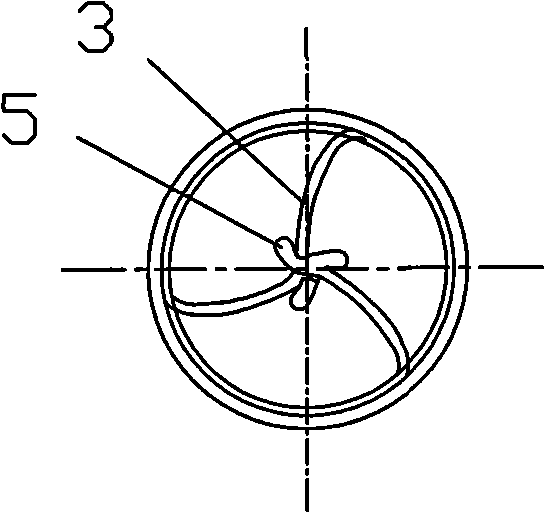

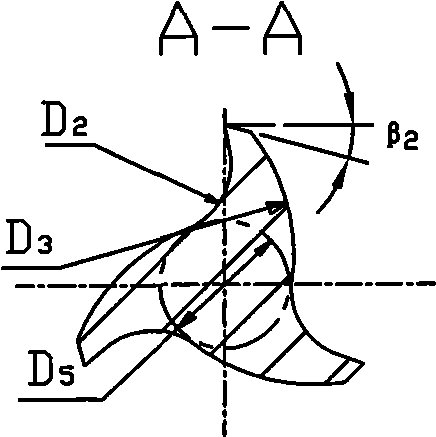

[0013] See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Figure 6 , The cutter body part 1 is composed of three (or two) main cutting edges 3, secondary cutting edges 4, rake faces 6 and flank faces 7 at the end of the ball nose cutter body, and the adjacent main cutting edges 3 are arranged between There is a transition groove edge 5, the helix angle ω of the secondary cutting edge 4 is 60°, and the rake angle a of the main cutting edge 3 1 And back angle β 1 Both are 15°, the rake angle of the secondary cutting edge 4 a 2 12°, clearance angle β 2 The radius D4 of the arc groove of the main cutting edge 3 is 1.5mm, and the radial cross-sectional shape of the spiral groove forming the rake face 6 is a circular arc with a radius D2 of 3.5mm. The flank 7 is composed of A main flank 8 with a width D1 of 1.5mm and a secondary flank 9 with a radius D3 of 7.5mm in a radial section. The blade length of the body part 1 is 60mm, and the knife diameter D5 is 20mm.

[0014] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com