Efficient coated control release urea and preparation thereof

A controlled-release urea and coating technology, which is applied in the direction of urea compound fertilizer, nitrogen fertilizer, fertilizer mixture, etc., can solve the problems of high cost and limited cost, and achieve the effects of simple manufacturing process, stable release rate and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

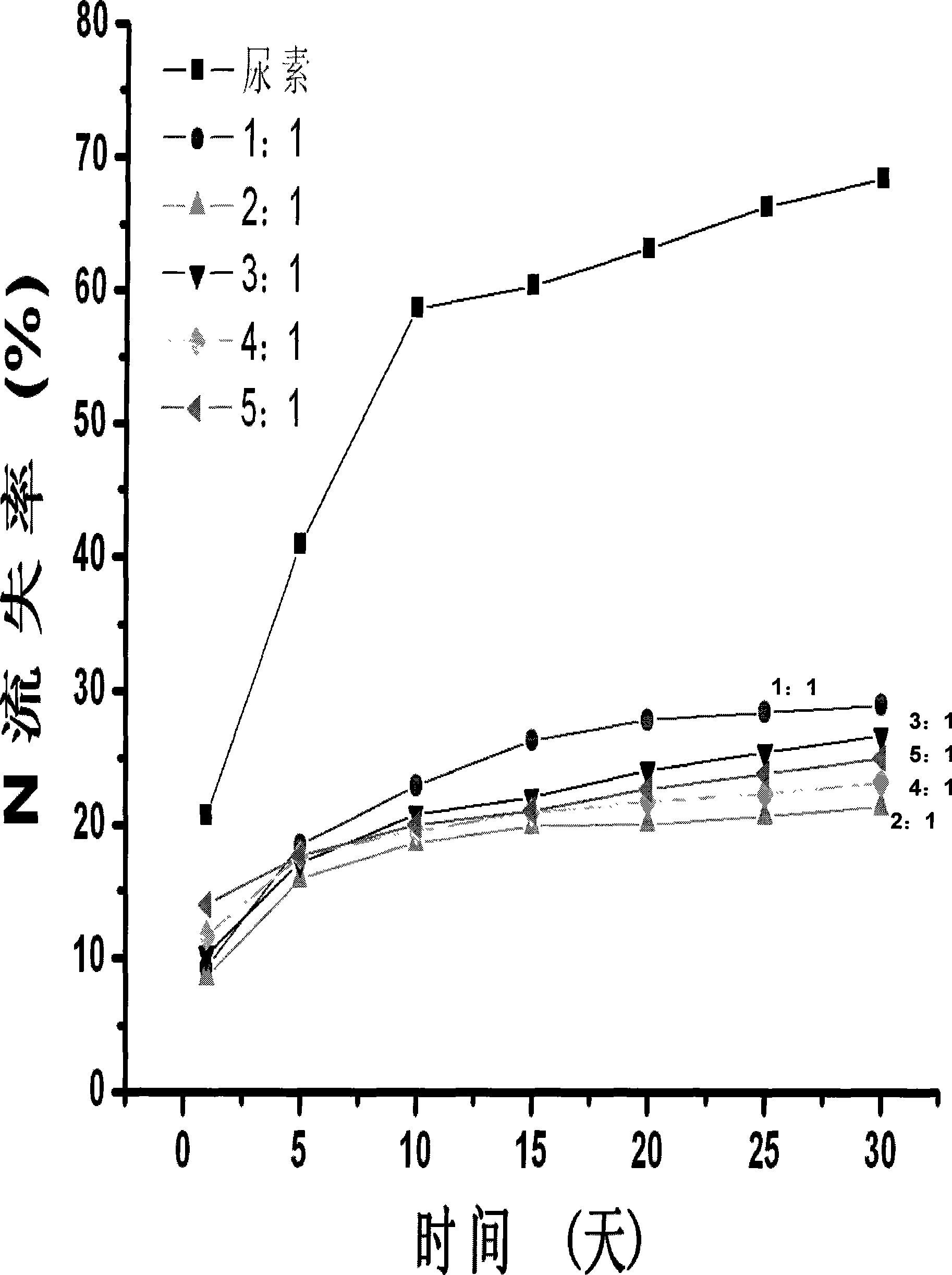

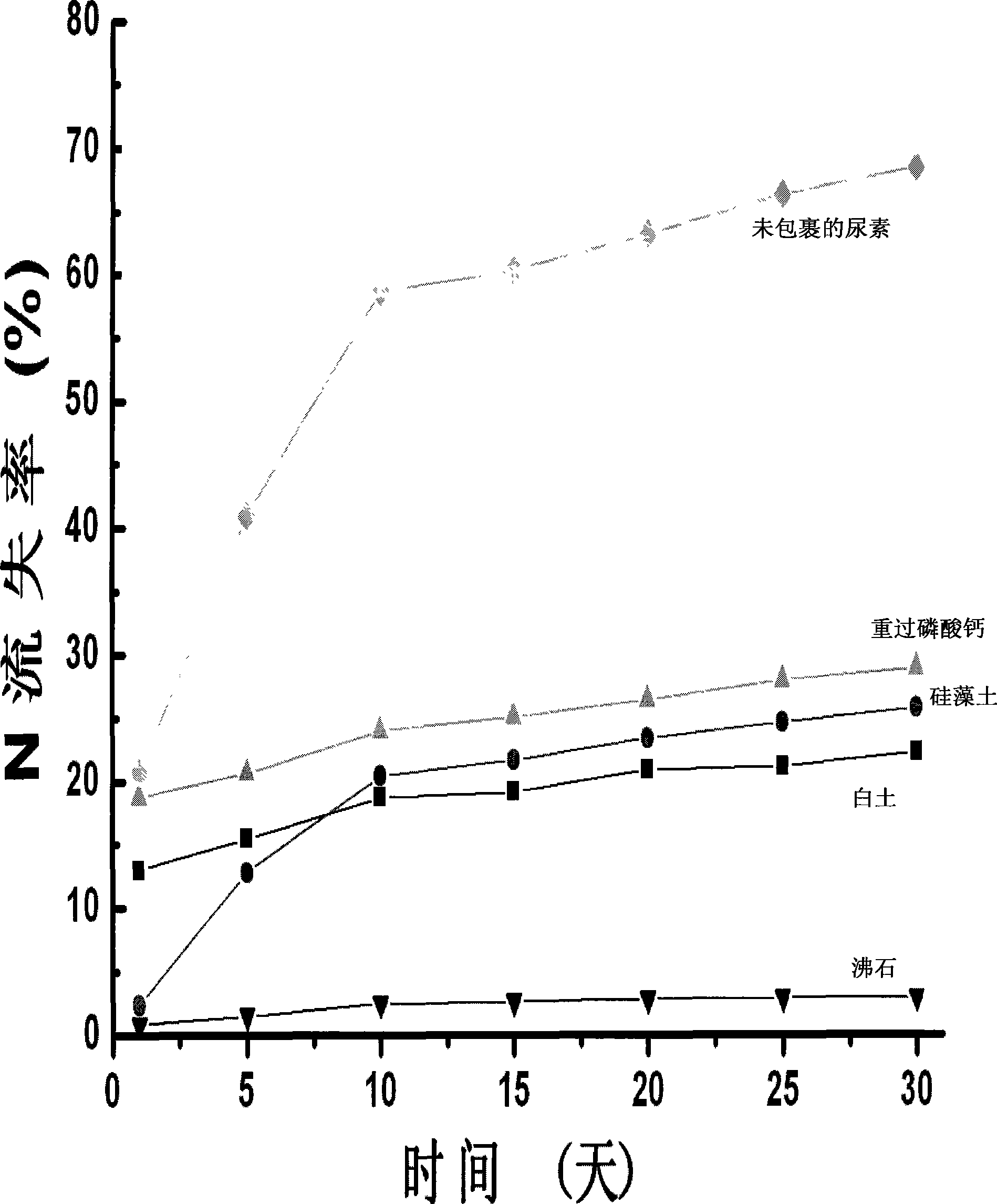

[0025] (1) Weigh 2.000Kg of urea and place it in a 50L electrothermal reaction kettle, wet the surface with 100ml of distilled water, raise the temperature to 105°C, and make the urea in a molten state; put in 1.000Kg of zeolite powder, keep warm and stir for 30min, and obtain zeolite after cooling and solidifying coated urea.

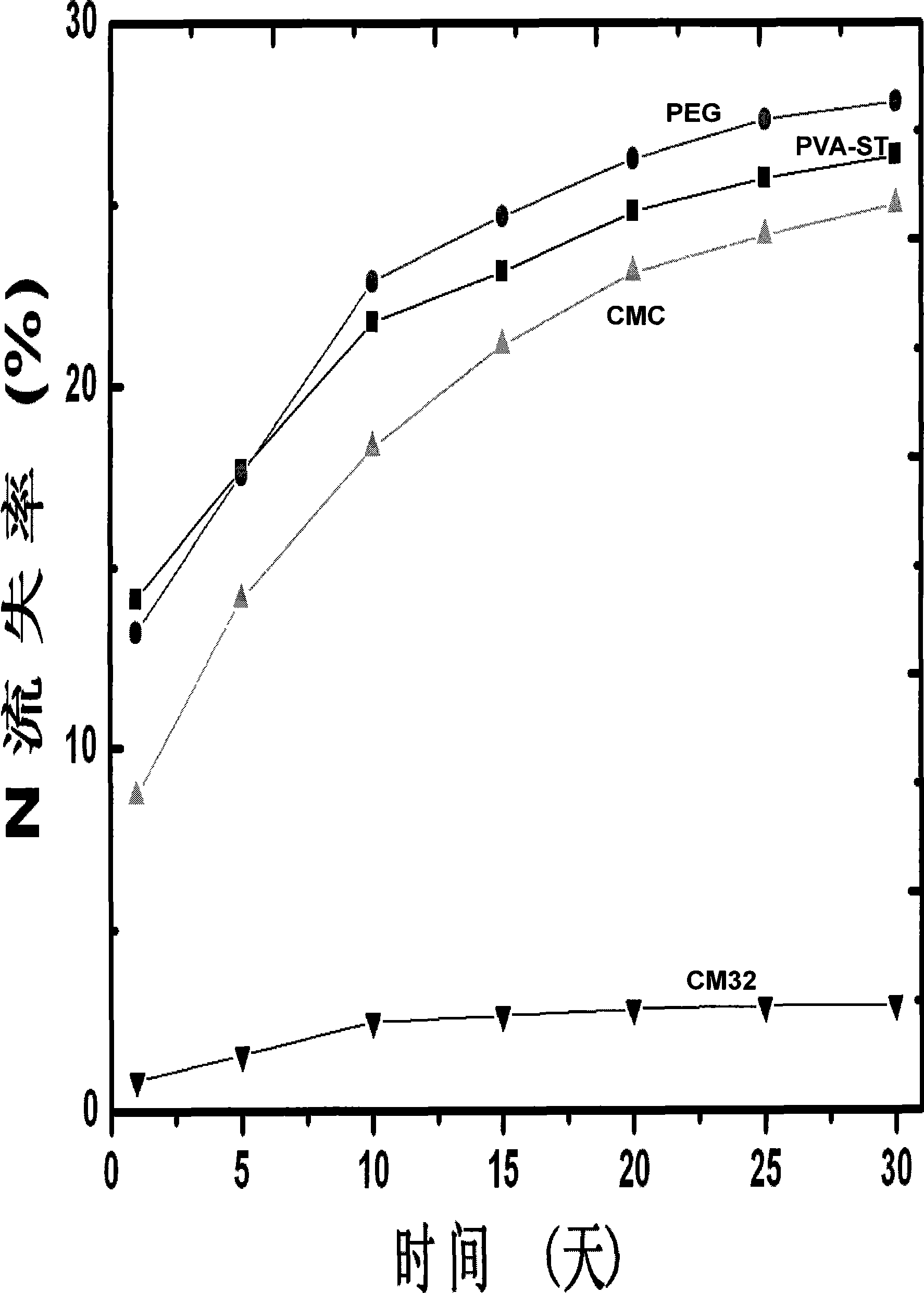

[0026] (2) Weigh 3.0Kg of carboxymethyl cellulose (CM32) and mix it with 30L of distilled water, stir to dissolve and heat to 100°C to melt it, and transfer the solution into a watering can while it is still hot. Spray 3L of the above-mentioned carboxymethylcellulose solution on the surface of the zeolite-coated urea obtained in step (1) with a watering can, stir at the same time, and coat; then place the product at 100°C for 2 hours and keep stirring during the heat preservation process . Cool to room temperature to obtain a powder product. The particle diameter range of the product is 1-6um.

Embodiment 2

[0028] (1) Weigh 2.000Kg of urea and place it in a 50L electrothermal reaction kettle, wet the surface with 100ml of distilled water, raise the temperature to 100°C, and make the urea in a molten state; put in 2.000Kg of zeolite powder, keep warm and stir for 30min, and obtain zeolite after cooling and solidifying coated urea.

[0029] (2) Weigh 4.0Kg of carboxymethyl cellulose (CM32) and mix it with 30L of distilled water, stir to dissolve and heat to 100°C to melt it, and transfer the solution into a watering can while it is still hot. Spray 1L of carboxymethylcellulose solution on the surface of the zeolite-coated urea obtained in step (1) with a watering can, and stir at the same time for coating; then place the product at 100° C. for 2 hours and keep stirring during the heat preservation process. Cool to room temperature to obtain a powder product. The particle diameter range of the product is 1-6um.

Embodiment 3

[0031] (1) Weigh 2.000Kg of urea and place it in an electric heating reaction kettle, wet the surface with 100ml of distilled water, raise the temperature to 110°C, and make the urea in a molten state. Put in 0.500Kg zeolite powder, keep warm and stir for 30min. After cooling to room temperature, zeolite-coated urea was obtained after solidification.

[0032] (2) Weigh again 4.0Kg carboxymethyl cellulose (CM32) and mix it with 30L distilled water, stir to dissolve and heat to 100°C to melt it. The carboxymethyl cellulose solution is sprayed on the surface of the zeolite-coated urea obtained in step (1), and stirred at the same time for coating; then the product is kept and dried at 90° C. for 5 hours, and continuously stirred during the heat preservation process. Cool to room temperature to obtain a powder product. The particle diameter range of the product is 1-6um.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com