Red phosphorus flame-retardant enhanced thermoplastic polyamide composition

A technology of thermoplastic polyamide and composition, applied in the field of thermoplastic polyamide composition, can solve the problems of red phosphorus failure, coating layer damage or partial damage, restriction, etc., and achieve the effect of good interface compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

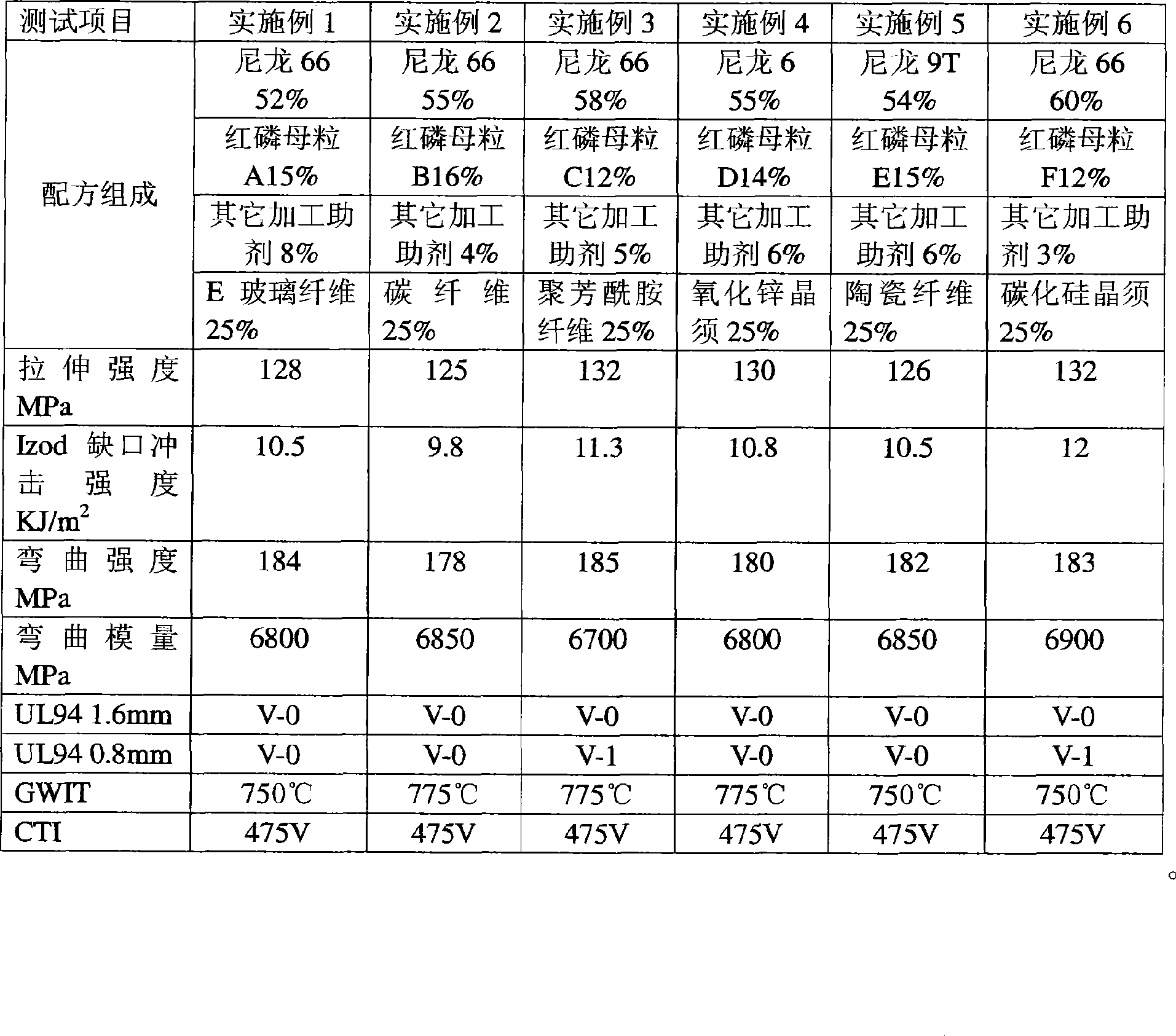

Examples

Embodiment Construction

[0023] 1. Preparation of microencapsulated red phosphorus powder

[0024] After removing yellow phosphorus and finely ground red phosphorus powder (particle size 50 μm), add zinc nitrate and ammonium phosphate under alkaline conditions, deposit a thin layer of zinc phosphate on the surface of red phosphorus powder, and then add phenol and formaldehyde, Silicone resin, reacting to produce composite coated red phosphorus powder of phenolic resin and silicone resin. The coated red phosphorus powder and nylon 6 are processed into red phosphorus masterbatch A with nylon 6 as the carrier resin through an extruder, and the phosphorus content of the red phosphorus masterbatch is 50%.

[0025] After removing yellow phosphorus and finely ground red phosphorus powder (particle size 50 μm), add zinc nitrate and boric acid under alkaline conditions, deposit a thin layer of zinc borate on the surface of red phosphorus powder, and then add epoxy resin and polyurethane after treatment Resin,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ignition point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com