Extract method for lectin of leguminous plants

A plant lectin and extraction method technology, which is applied in the field of extraction of useful plant components, can solve the problems of chemical reagent components leftover and the like, and achieve the effects of overcoming chemical reagent components leftover and overcoming long extraction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

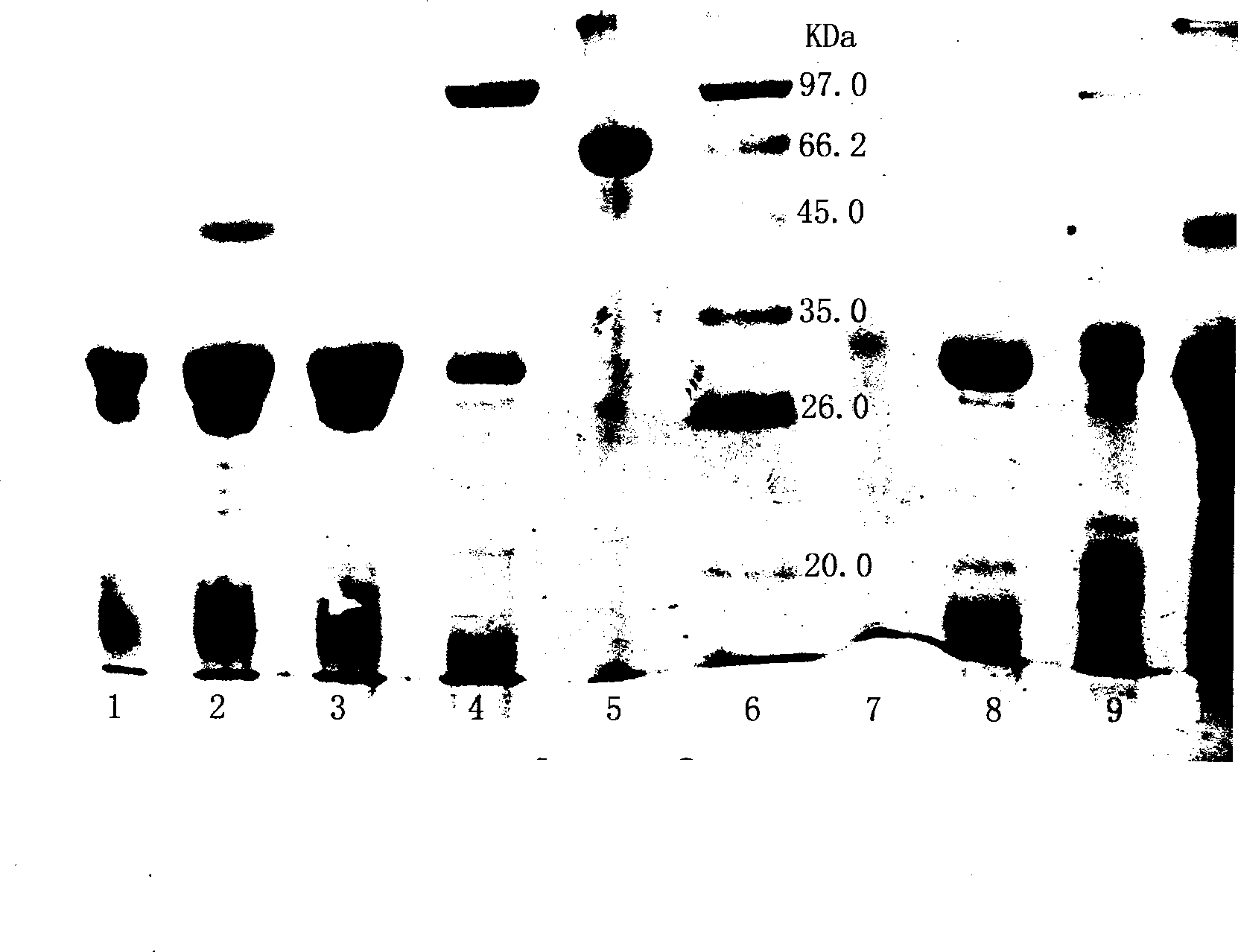

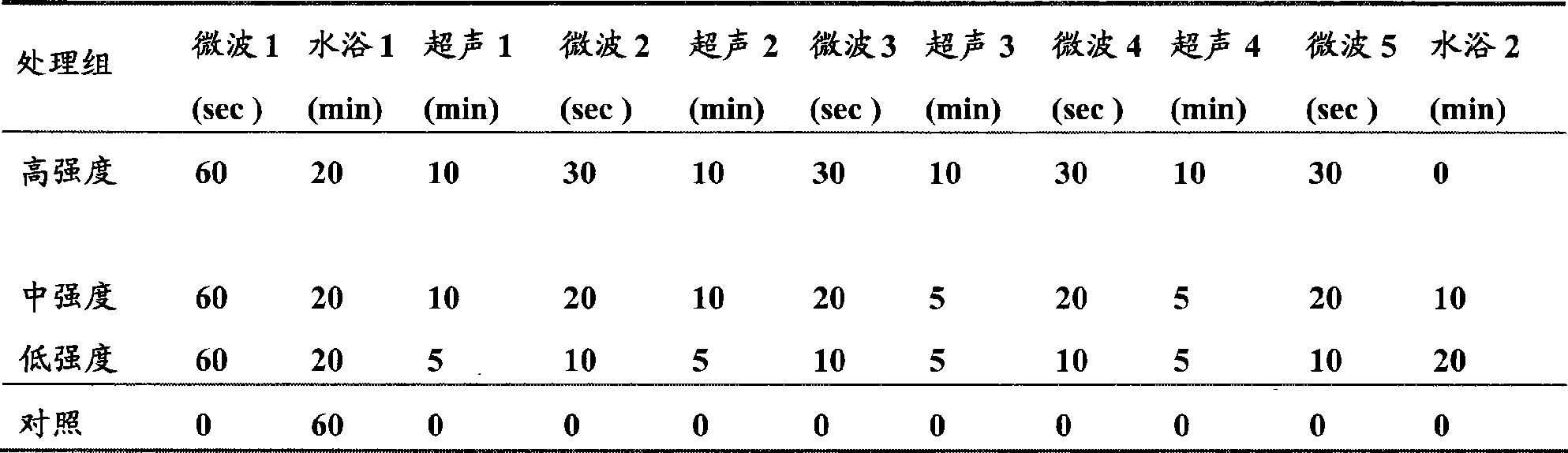

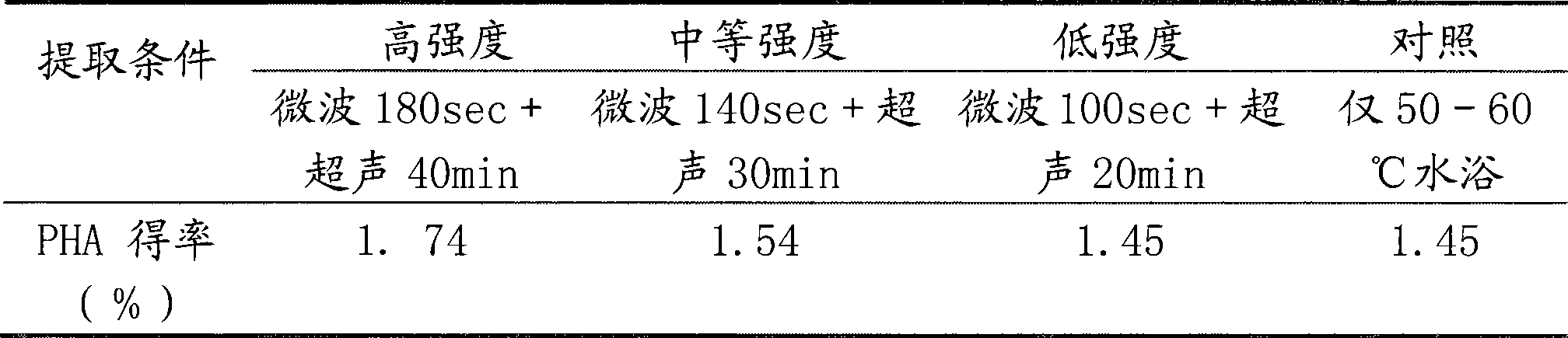

[0020] Example 1: Preparation of kidney bean lectin

[0021] First take the dried kidney bean kernels, wash them with tap water for 3-5 minutes, remove the sundries, then dry them at low temperature or hang them in the sun. Mechanically pulverize and pass through a 60-mesh sieve to become soybean powder. Weigh 50g of soybean powder and put it into a polyethylene bag, add 250ml of 0.9% normal saline, and seal it with a sealing machine. Put it in the microwave and set the power to 800W. Divided into high, medium and low treatment intensity groups and a control group. In the high-intensity treatment group, the first microwave heating time was 60 seconds, and then placed in a 50-60°C water bath for 20 minutes, stirred 5 times during the period, and then the second microwave treatment was performed for 30 seconds, and then placed in a 100w ultrasonic cleaner with a capacity of 6L. Add 3 bags of treated samples in 4L water, treat for 10 minutes, then perform the third microwave t...

Embodiment 2

[0027] Example 2: Preparation of kidney bean lectin

[0028] In this embodiment, the processing capacity and method are the same as those in Embodiment 2. Only change the temperature setting to 30-40°C. It has been determined that in the temperature range of 30-40 ° C, the PHA extraction results of three microwave and ultrasonic combinations of high, medium and low are shown in Table 2.

[0029] Table 3 The extraction rate of kidney bean PHA by different microwave and ultrasonic combinations at 30-40℃

[0030]

Embodiment 3

[0031] Example 3: Preparation of lentil lectin

[0032] In this embodiment, two temperature treatments are adopted, namely, 40-60° C. for 2 hours and 4-10° C. refrigerator for 12-14 hours. Microwave and ultrasonic treatment were not applied.

[0033] The pretreatment mode of lentil is the same as embodiment 1. The crushed bean flour is passed through a 60-mesh sieve. Add the same physiological saline or phosphate buffer as in Example 1 at a ratio of 1:5. Put them into 40-60°C heat preservation container and 4-10°C refrigerator respectively. Stir once every 15-30min. The extraction time of the 40-60°C heat preservation extraction group is 2 hours, and the 4-10°C refrigerator treatment is 12-14 hours. The processing after extraction is the same as in Example 1. The results are shown in Table 4.

[0034] Table 4 Extraction rate of lentil lectin at 40-60℃ and 4-10℃

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com