Solar film battery assembly for architecture

A technology of solar thin film and battery components, applied in electrical components, sustainable buildings, circuits, etc., can solve problems such as products that have not found applications of thin film battery components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

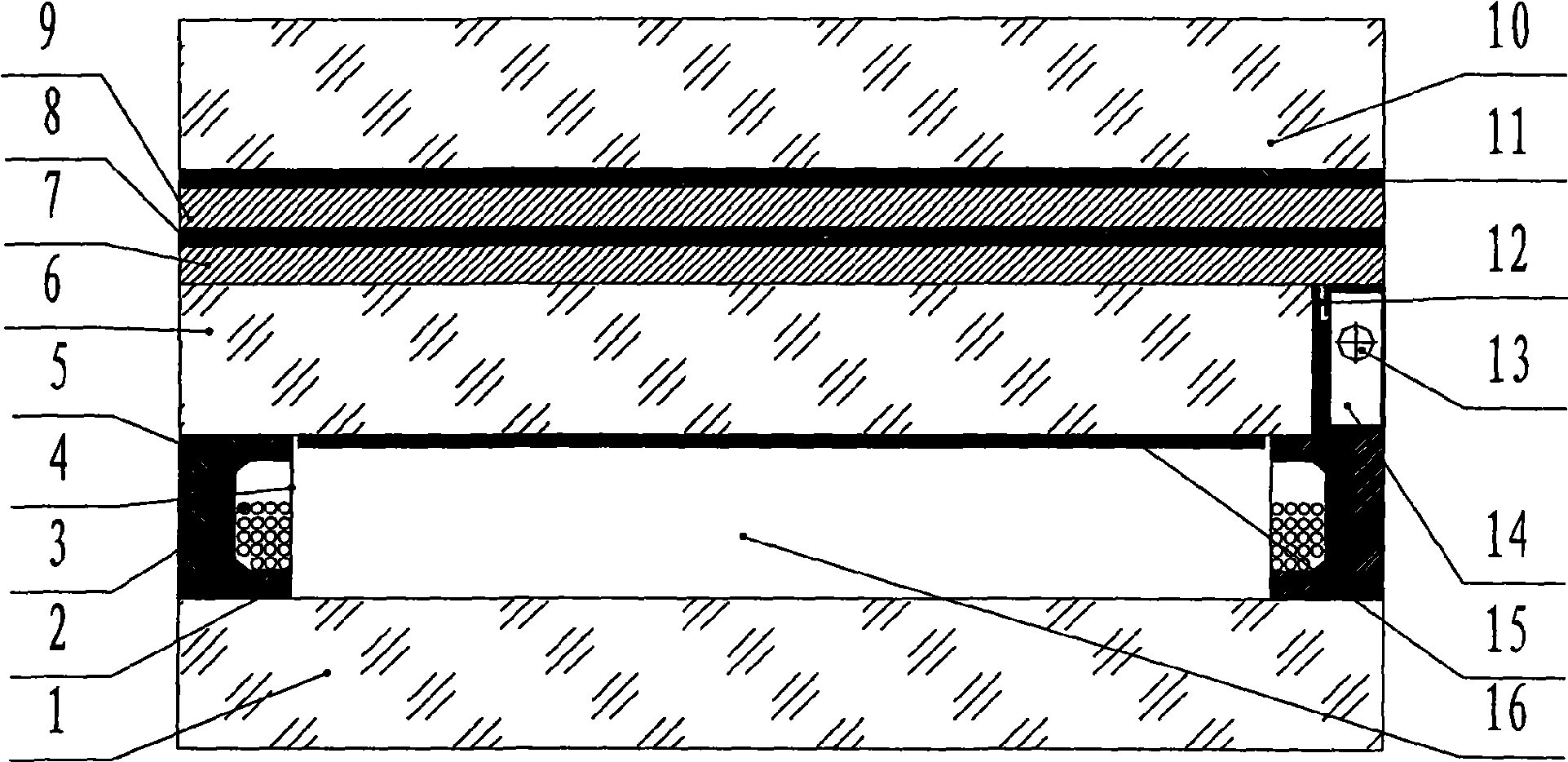

[0024] Example 1: figure 1 , image 3 Among them, the solar thin film battery module is composed of conductive film glass layer 10, thin film battery layer 9, aluminum film layer 8, EVA layer 7, float glass layer 6 and hollow glass layer 1 from top to bottom. The two ends between the hollow glass layer 1 and the hollow glass layer 1 are respectively provided with spacer bars 4 , and the spacer bar 4 separates the float glass layer 6 from the hollow glass layer 1 to form a hollow cavity 16 . A junction box 14 with a Schottky diode 13 is installed on the outside of one of the spacer bars 4 to the side of the corresponding float glass layer 6; an electrode is respectively drawn out on the conductive film glass layer 10 and the aluminum film layer 8, and two electrodes 12 are drawn out. It is connected with the circuit in the junction box 14.

[0025] The lower side of the conductive film glass layer 10 is plated with a steel tin oxide film layer 11 by a vapor phase deposition m...

Embodiment 2

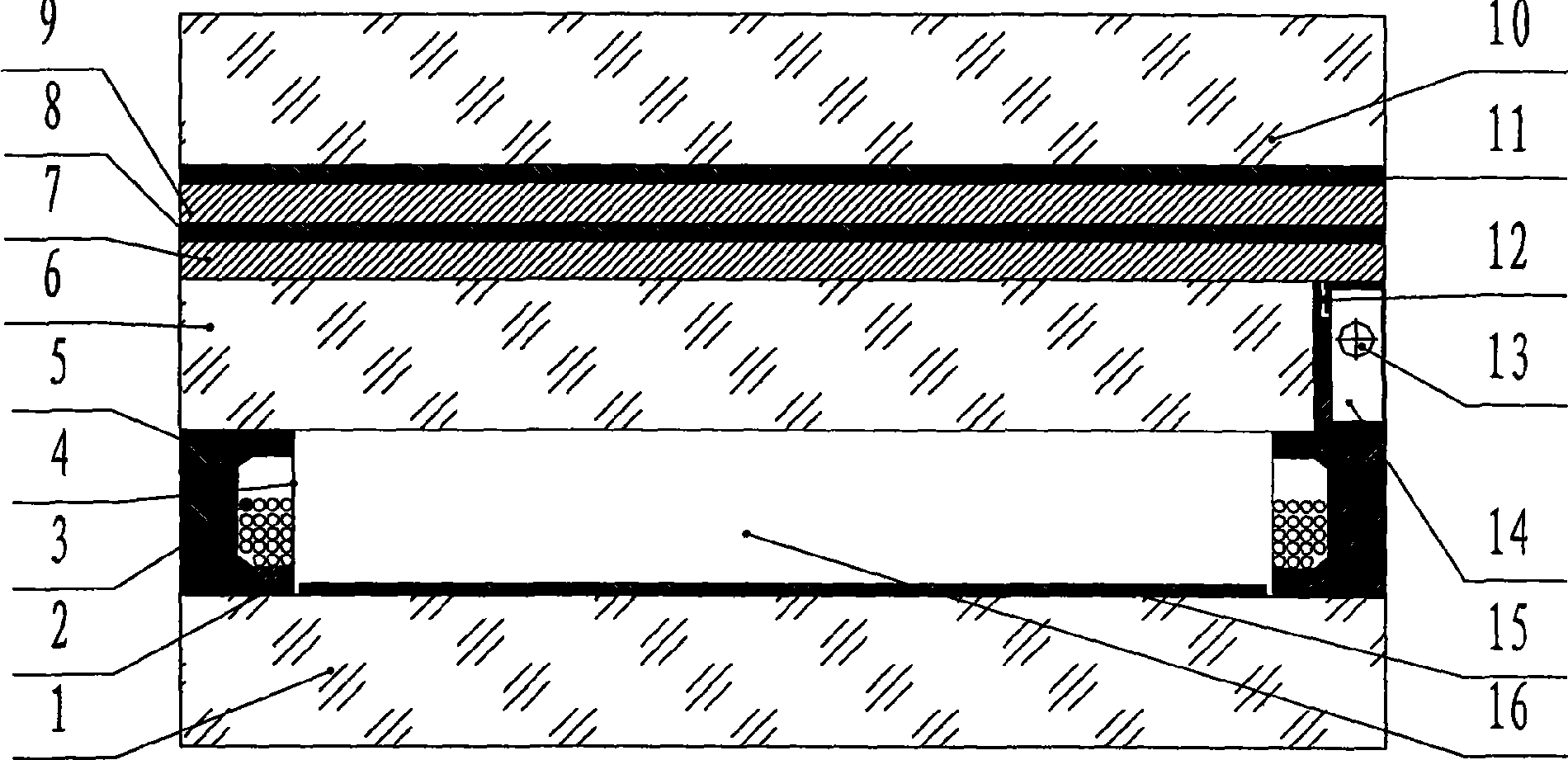

[0031] Embodiment 2: as figure 2 , image 3 As shown, the difference from Embodiment 1 is that the hollow cavity 16 is filled with an inert gas; the LOW-E film layer 16 is coated on the upper side of the hollow glass layer 1, and the rest are the same, and will not be repeated here.

Embodiment 3

[0032] Embodiment 3: The difference from Embodiment 1 is that the LOW-E film layer 15 is coated before the tempering of the insulating glass layer 1 by vapor deposition, so that the LOW-E film layer 15 and the insulating glass layer 1 are thermally fused together. The rest are the same and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com