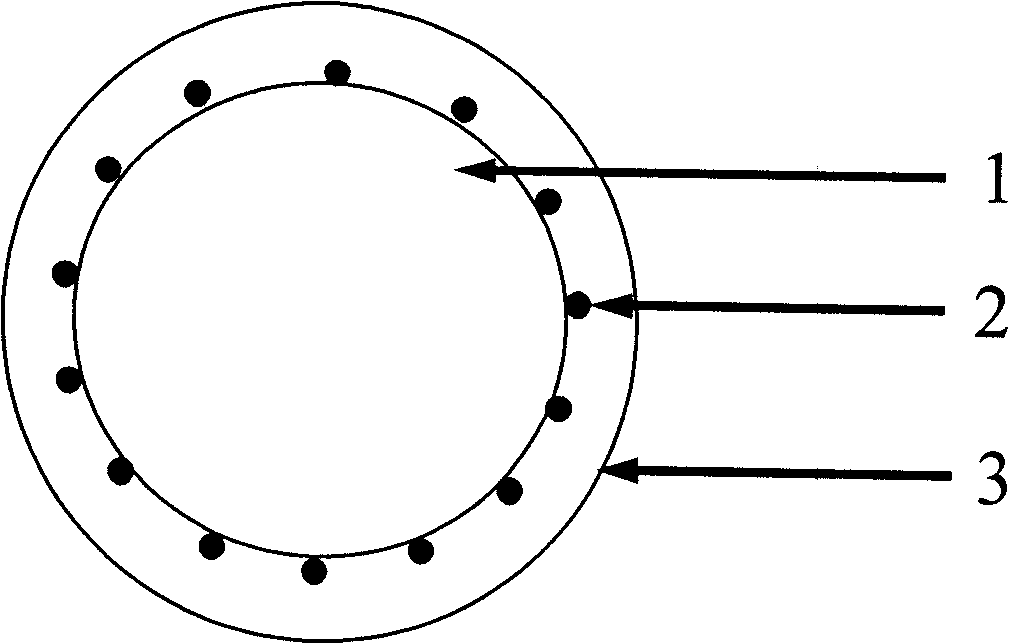

Method for preparing carbon fiber loaded composite photocatalysis membrane

A composite photocatalysis and carbon fiber technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of high-temperature sintered carrier structures that are easily broken and difficult to recycle, etc. problem, to achieve excellent photocatalytic effect and control the effect of easy cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

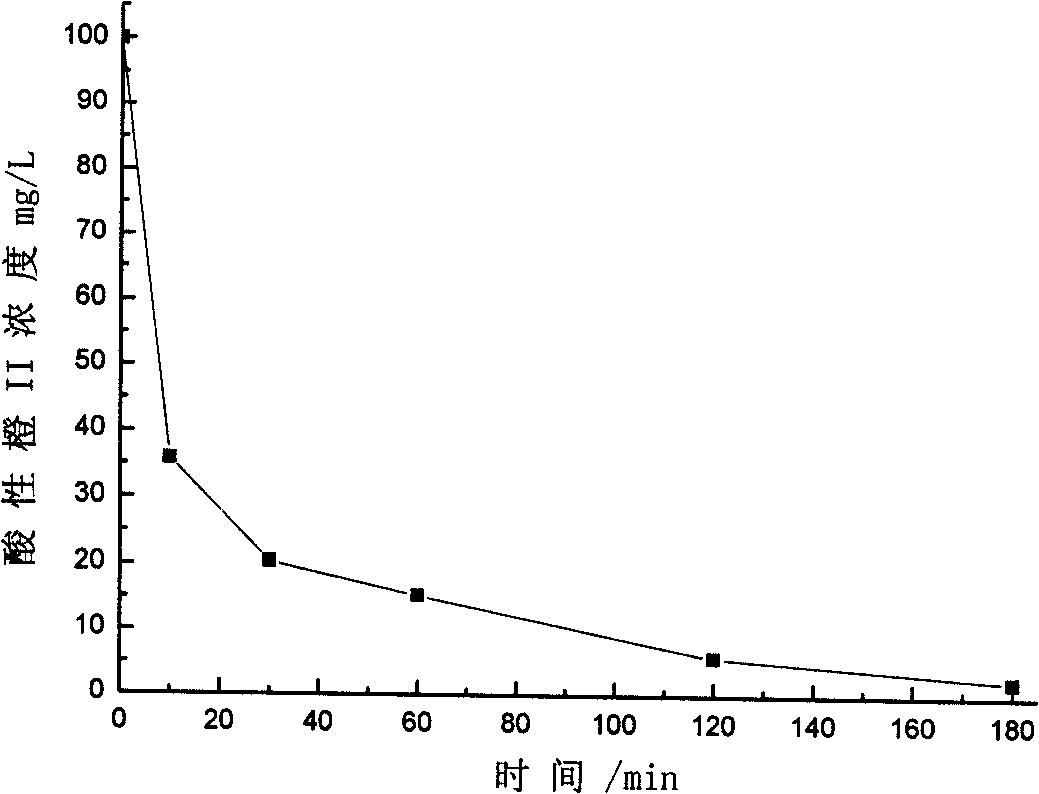

Examples

Embodiment 1

[0016] 1) Select PAN-based carbon fiber and put it into a reaction vessel, and add 65%-68% concentrated nitric acid, wherein the mass ratio of carbon fiber to concentrated nitric acid is 0.8:100, and the volume of the reaction solution is 2:6 of the volume of the reaction vessel in an oil bath Heating, condensing and refluxing for 3 hours, taking it out and washing it with deionized water to pH 6-7, wherein the diameter of the single fiber is 4-6 μm;

[0017] 2) Immerse the treated fiber in 10g / L SnCl 2 solution for 10-20min, in which fiber and SnCl 2 The bath ratio of the solution is 1:250, take it out and dry it, then impregnate it in 0.2g / L PdCl 2 10-20min in the solution, in which fiber and PdCl 2 The bath ratio of the solution is 1:20, and it is dried in an oven at 40-60°C for 1 hour;

[0018] 3) Prepare titanium sol with isopropyl titanate as a precursor, propylene glycol as a solvent, and hydrochloric acid as a hydrolysis inhibitor, wherein the molar ratio of isoprop...

Embodiment 2

[0020] 1) Select PAN-based carbon fiber and put it into a reaction vessel, and add 65%-68% concentrated nitric acid, wherein the mass ratio of carbon fiber to concentrated nitric acid is 1.3:100, and the volume of the reaction solution is 2:7 of the volume of the reaction vessel in an oil bath Heating, condensing and refluxing for 6 hours, taking it out and washing it with deionized water until the pH is 6-7, and the diameter of the single fiber is 4-6 μm;

[0021] 2) Immerse the treated fiber in 10g / L SnCl 2 solution for 10-20min, in which fiber and SnCl 2 The bath ratio of the solution is 1:500, take it out and dry it and then impregnate it in 0.5g / L PdCl 2 10-20min in the solution, in which fiber and PdCl 2 The bath ratio of the solution is 1:100, and it is dried in an oven at 40-60°C for 2 hours;

[0022] 3) Prepare titanium sol with isopropyl titanate as a precursor, propylene glycol as a solvent, and hydrochloric acid as a hydrolysis inhibitor, wherein the molar ratio...

Embodiment 3

[0024] Select PAN-based carbon fiber and put it into the reaction vessel, and add 65%-68% concentrated nitric acid, wherein the mass ratio of carbon fiber to concentrated nitric acid is 1.3:100, and the volume of the reaction solution is 2:7 of the volume of the reaction vessel. Heating in an oil bath Condensate and reflux for 6 hours, take it out and wash it with deionized water until the pH is 6-7, and the diameter of the single fiber is 4-6 μm;

[0025] 2) Immerse the treated fiber in 10g / L SnCl 2 solution for 10-20min, in which fiber and SnCl 2 The bath ratio of the solution is 1:500, take it out and dry it and then impregnate it in 0.5g / L PdCl 2 10-20min in the solution, in which fiber and PdCl 2 The bath ratio of the solution is 1:100, and it is dried in an oven at 40-60°C for 2 hours;

[0026] 3) Prepare titanium sol with isopropyl titanate as a precursor, propylene glycol as a solvent, and hydrochloric acid as a hydrolysis inhibitor, wherein the molar ratio of isopr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com