Aluminum alloy sheet for cold press forming, method of manufacturing the same, and cold press forming method for aluminum alloy sheet

A cold-press forming, aluminum alloy plate technology, applied in the field of cold-press forming, can solve the problems of inability to use common lubricants, cracks in bending parts, complicated structure of presses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

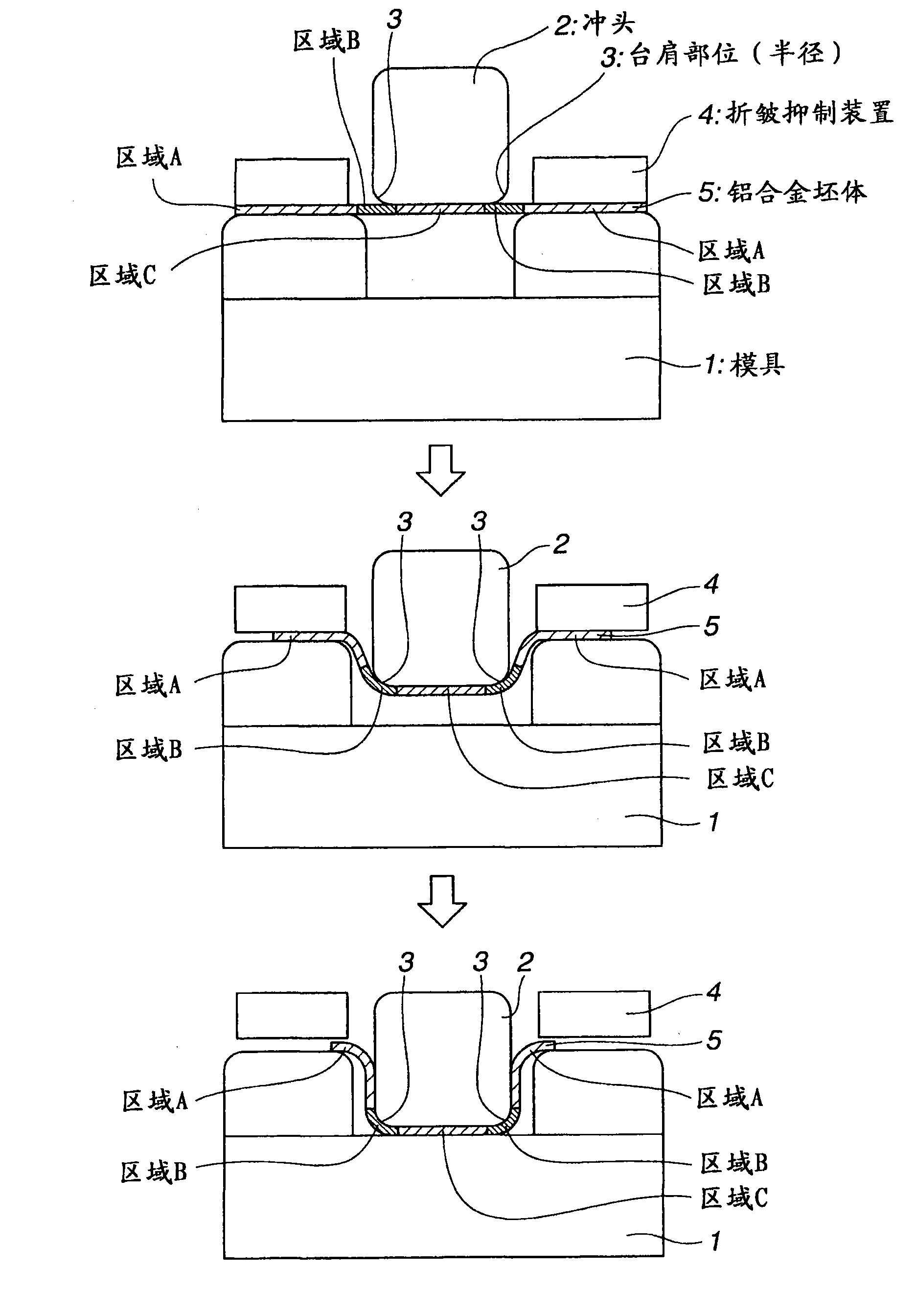

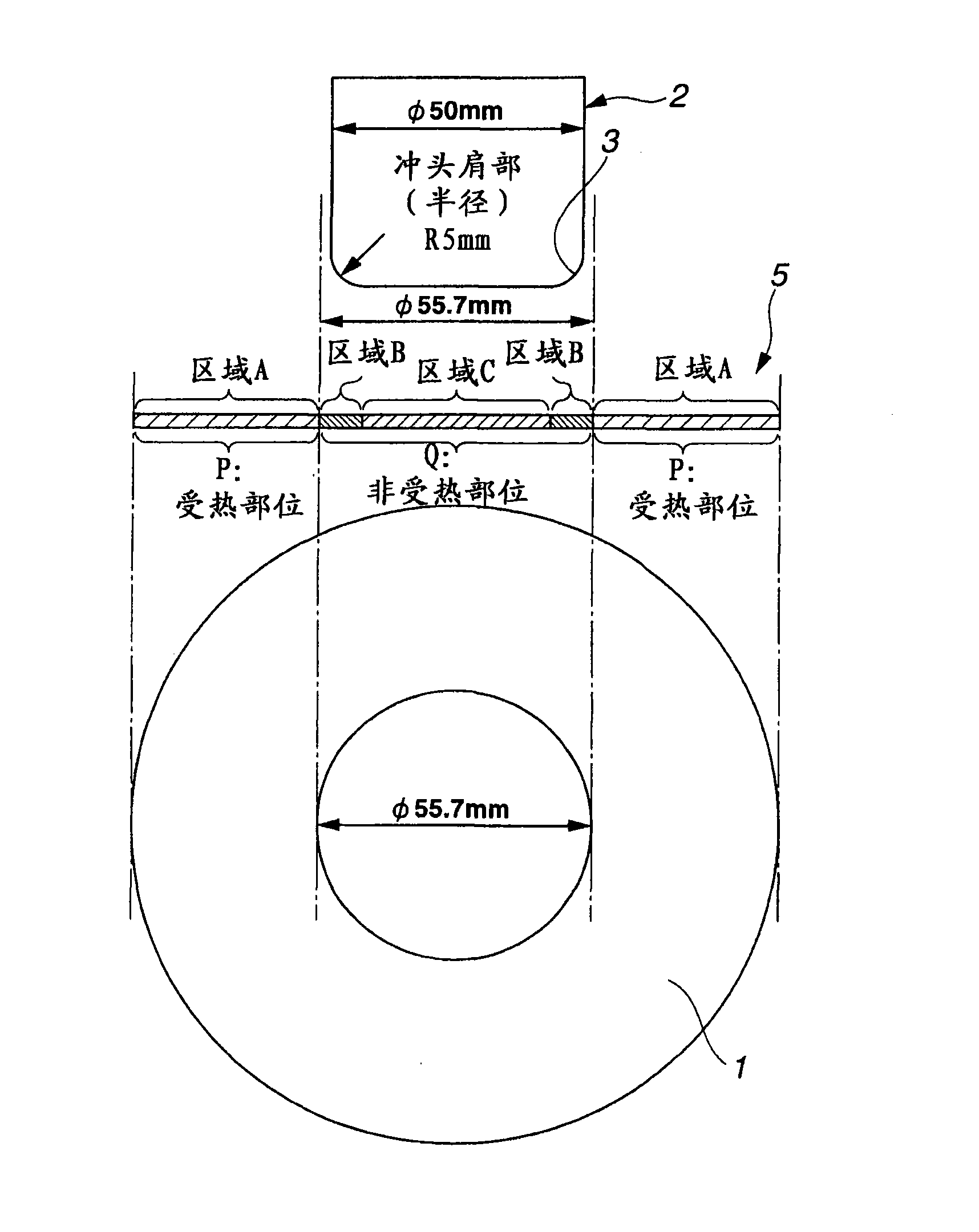

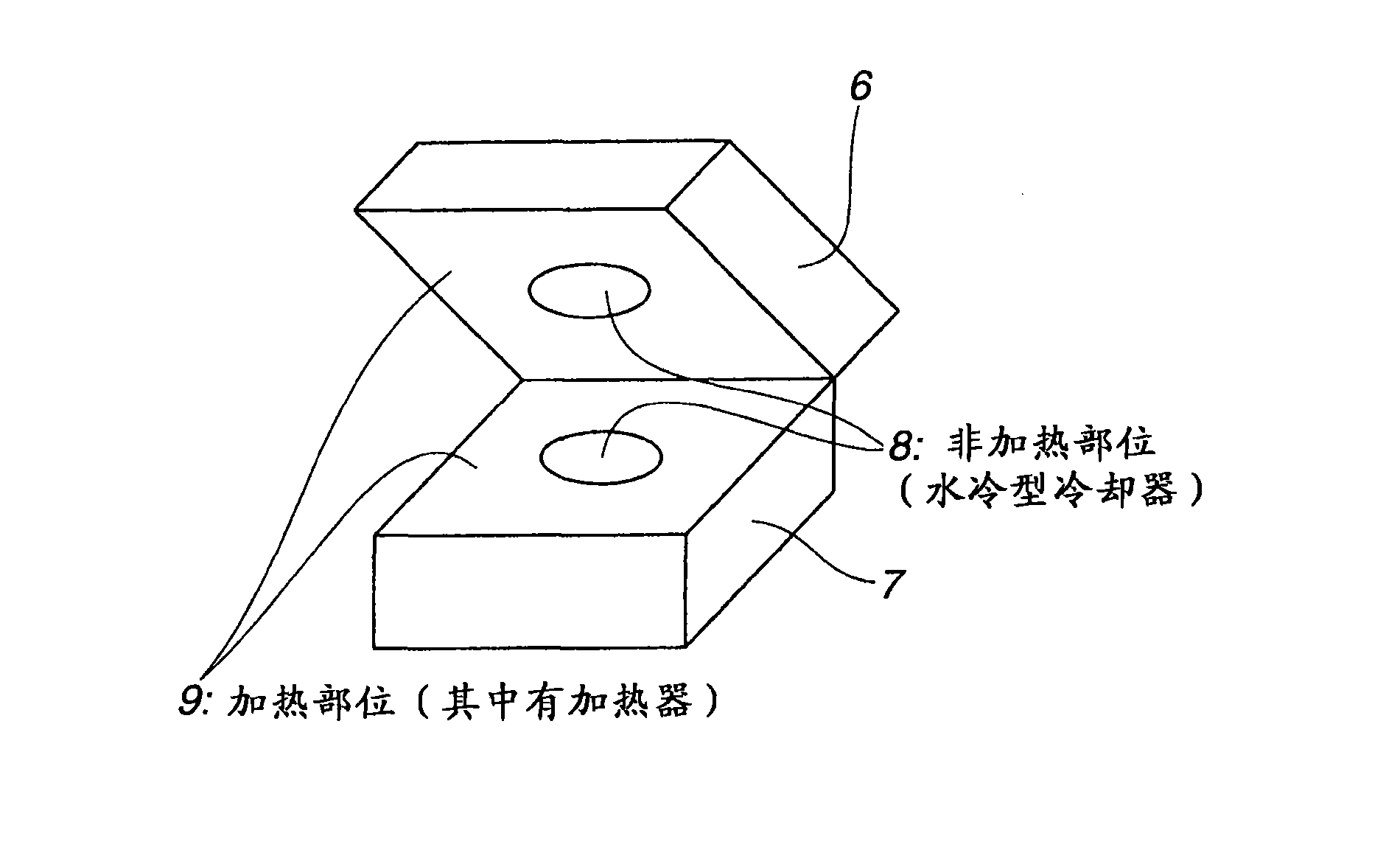

Embodiment 1

[0106] Aluminum alloys A1 to A6 as shown in Table 1 were melted and adjusted in composition, and the melts were cast by a DC casting method to produce aluminum alloy ingots. Each ingot was soaked at 530° C. for 10 hours, and hot-rolled and cold-rolled according to an ordinary method to obtain a 1 mm-thick alloy plate. Then, each alloy plate obtained was subjected to solution treatment at 530° C., followed by rapid cooling to room temperature. After solution treatment and rapid cooling, each alloy plate was kept at room temperature for 60 days. Then, at the time of pressing, the portion of each alloy sheet to be the pressed peripheral portion was subjected to partial recovery heat treatment under the heating conditions shown in Table 2. After each alloy plate as a whole is cooled to normal temperature, within a period of 24 hours at normal temperature, the alloy plate is used for the strength (tensile strength and 0.2% yield stress) of the non-heated part and the heated part, ...

Embodiment 2

[0124] On the basis of the process, Example 2 is mainly used to demonstrate the effect of the method described in claims 7 and 12 of the present invention. However, it should be noted here that embodiments falling outside the conditions defined in claims 6 and 11 but falling within the conditions defined in claims 7 and 12 are also described for reference. Here, the embodiment that satisfies the limitations of claims 7 and 12 is referred to as the "embodiment of the second category" (of the present invention), while the implementation that satisfies the limitations of claims 6 and 11 but does not satisfy the limitations of claims 7 and 12 Examples are referred to as "First Class Examples" (of the present invention), while Examples that do not satisfy both sets of conditions are referred to as "Comparative Examples".

[0125] Aluminum alloys B1 to B3 shown in Table 3 were melted, and then the melts were cast by a DC casting method to produce aluminum alloy ingots having chemica...

Embodiment 3

[0150] The rolled plate of alloy B1 used in Example 2 was prepared as a test sample, and solution treatment, aging and partial recovery heat treatment were carried out by the following method: wherein the aging condition after solution treatment and the following conditions such as in the partial recovery heat treatment The heating temperature, heating time, heating rate, and cooling rate achieved in 2 were the same as in Condition 2 shown in Table 4. However, it should be noted here that in Example 3, the regions of the heated part and the non-heated part were changed differently in the partial recovery heat treatment, as shown in Table 8. Three days after the partial recovery heat treatment, under the same test conditions as in Table 1, the green body that has undergone partial recovery heat treatment in this area was used for the cylindrical deep drawing test to determine the LDR. The results are shown in Table 8.

[0151] Table 8

[0152] condition

Number...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield stress | aaaaa | aaaaa |

| yield stress | aaaaa | aaaaa |

| yield stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com