A method for improving the yield of dry granulation granules of traditional Chinese medicine raw medicinal materials powder

A technology for dry granulation and raw medicinal materials, applied in the directions of inorganic inactive ingredients, bulk delivery, etc., can solve the problems of reducing patient compliance, large single dose, reducing economic benefits, etc., to improve fluidity and simple methods. , the effect of prolonging the production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

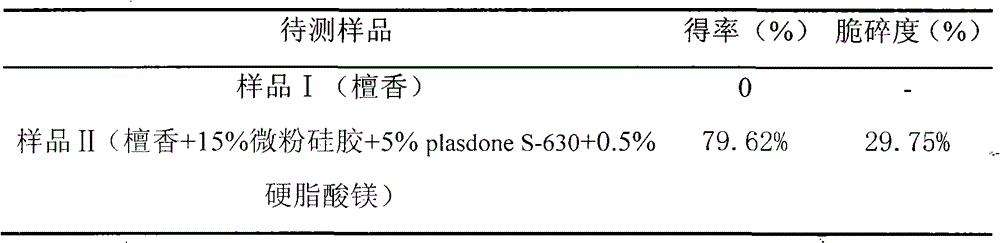

[0017] Embodiment 1: dry granulation of raw material powder of sandalwood

[0018] Preparation of Sandalwood Granules

[0019] Take sandalwood crude drug powder (passed through 80 mesh sieve) and directly dry granulate to obtain sample I.

[0020] Get sandalwood raw medicinal material powder (crossing 80 mesh sieves), add micropowder silica gel (crossing 200 mesh sieves), 5% plasdoneS-630 (crossing 120 mesh sieves), 0.5% magnesium stearate ( pass through a 120-mesh sieve), use a double-cone mixer to mix for 2 minutes, and then dry granulate to obtain sample II.

[0021] The establishment of particle evaluation index:

[0022] Yield: Take 30g of the above-mentioned granules, accurately weigh the mass, put them in the prescribed 10-mesh and 80-mesh medicine sieves, sieve them in a horizontal state, go back and forth from left to right, tap gently for 3 minutes while sieving, accurately weigh the weight, and calculate 10- 80 mesh particle yield. [Granule yield (%)=10-80 mesh ...

Embodiment 2

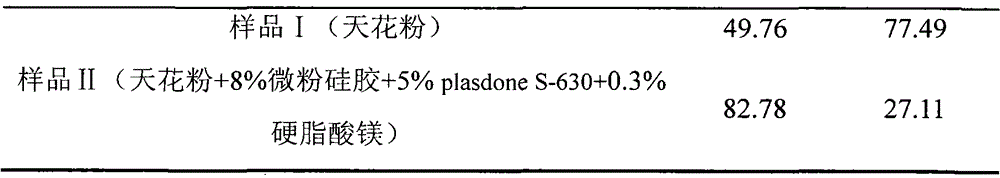

[0028] Embodiment 2: Trichosanthes crude medicinal material powder dry granulation

[0029] Preparation of trichosanthes granules

[0030] Sample Ⅰ was obtained by direct dry granulation of the raw medicinal material powder of Trichosanthum pollen (passed through a 80-mesh sieve).

[0031] Get the crude medicinal material powder of Trichosanthes officinalis (passes 80 mesh sieves), adds by weight the micropowder silica gel (passes 200 mesh sieves) that accounts for prescription total amount 8%, 3% plasdoneS-630 (passes 120 mesh sieves), 0.3% magnesium stearate (through a 120-mesh sieve), mixed for 2 minutes with a double-cone mixer, and then dry-granulated to obtain sample II.

[0032] The establishment of evaluation indicators:

[0033] Yield: Take 30g of the above-mentioned granules, accurately weigh the mass, put them in the prescribed 10-mesh and 80-mesh medicine sieves, sieve in a horizontal state, go back and forth, tap 3 minutes while sieving, accurately weigh the wei...

Embodiment 3

[0040] Embodiment 3: dry granulation of senna raw medicinal material powder

[0041] The raw senna powder (passed through a 60-mesh sieve) was directly dry-granulated to obtain sample I.

[0042] Get the raw senna powder (cross 60 mesh sieve), add 0.1% micropowder silica gel (cross 200 mesh sieve), 0.1% plasdoneS-630 (cross 120 mesh sieve), 0.1% stearin by weight Magnesium acid (through a 120-mesh sieve), mixed with a double-cone mixer for 2 minutes, and then dry-granulated to obtain sample II.

[0043] The establishment of evaluation indicators:

[0044] Yield: Take 30g of the above-mentioned granules, accurately weigh the mass, put them in the prescribed 10-mesh and 80-mesh medicine sieves, sieve in a horizontal state, go back and forth, tap 3 minutes while sieving, accurately weigh the weight, and calculate 10- 80 mesh particle yield. [Granule yield (%)=10-80 mesh grain yield / grain total mass*100%]

[0045] Friability: Take an appropriate amount of granules, pass throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com