Fly ash pipe gas flow crushing process

A technology of airflow crushing and conveying pipelines, which is applied in the direction of grain processing, etc., can solve the problems of high energy consumption and high power of driving motors, and achieve the effects of simple system, reduced investment and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

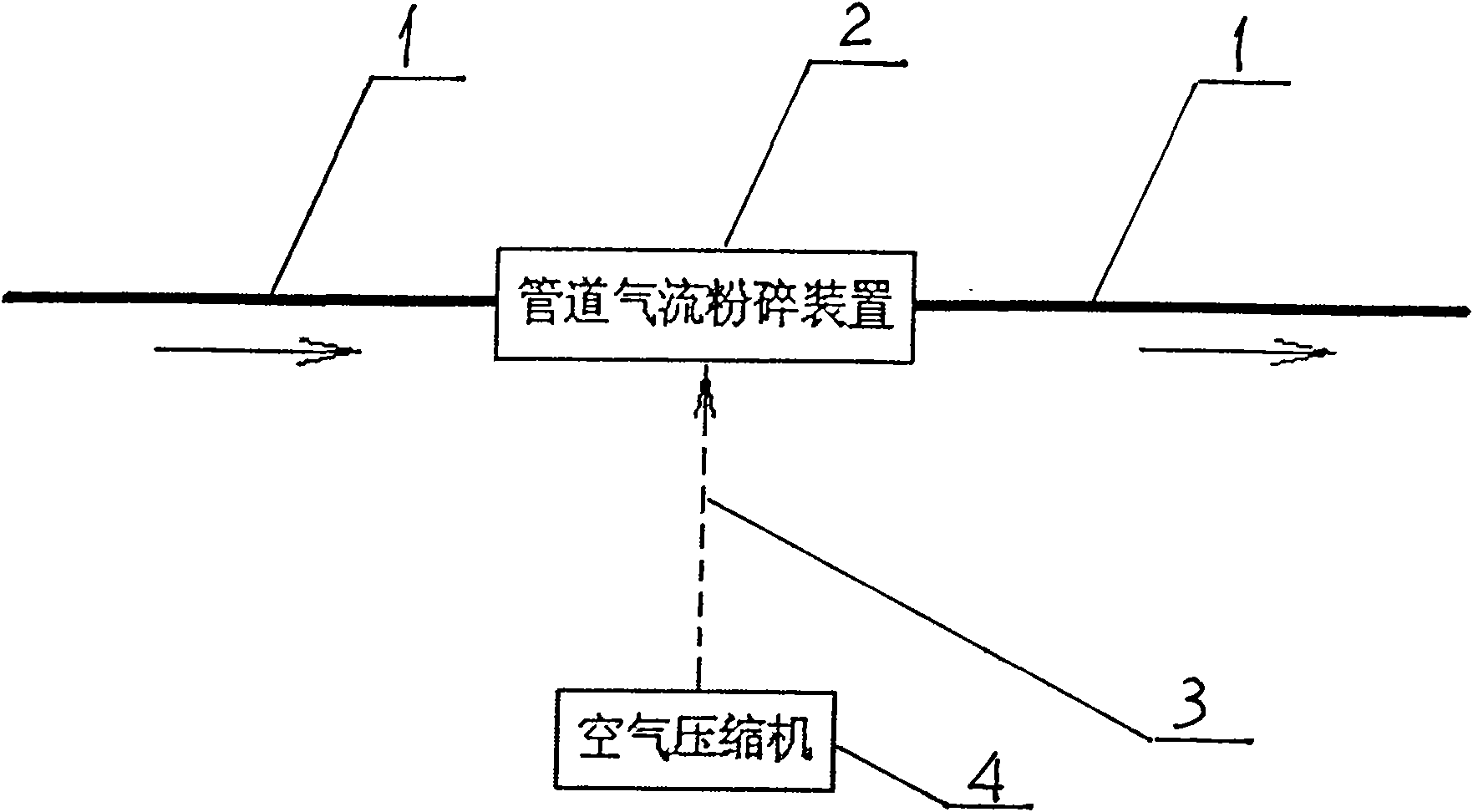

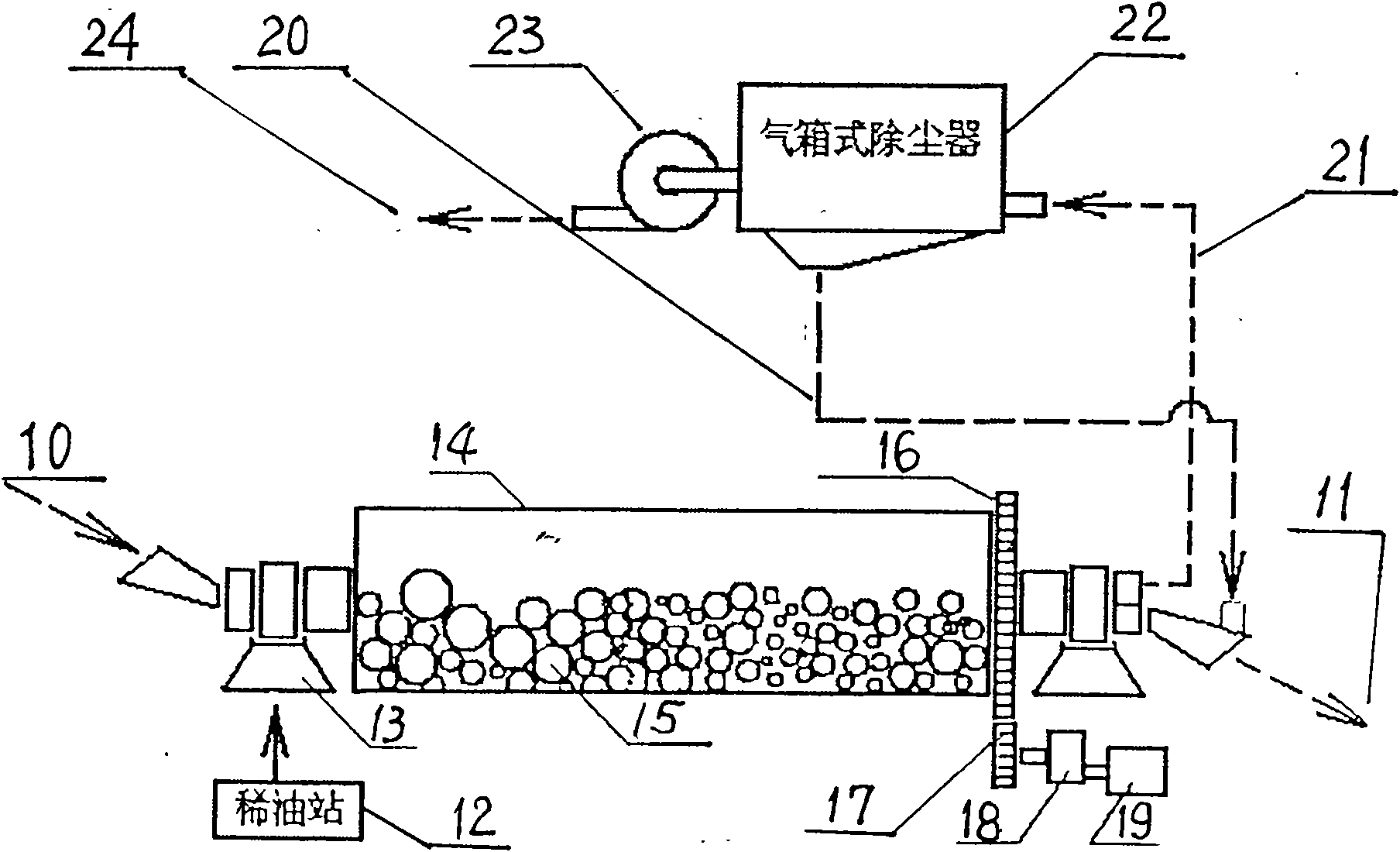

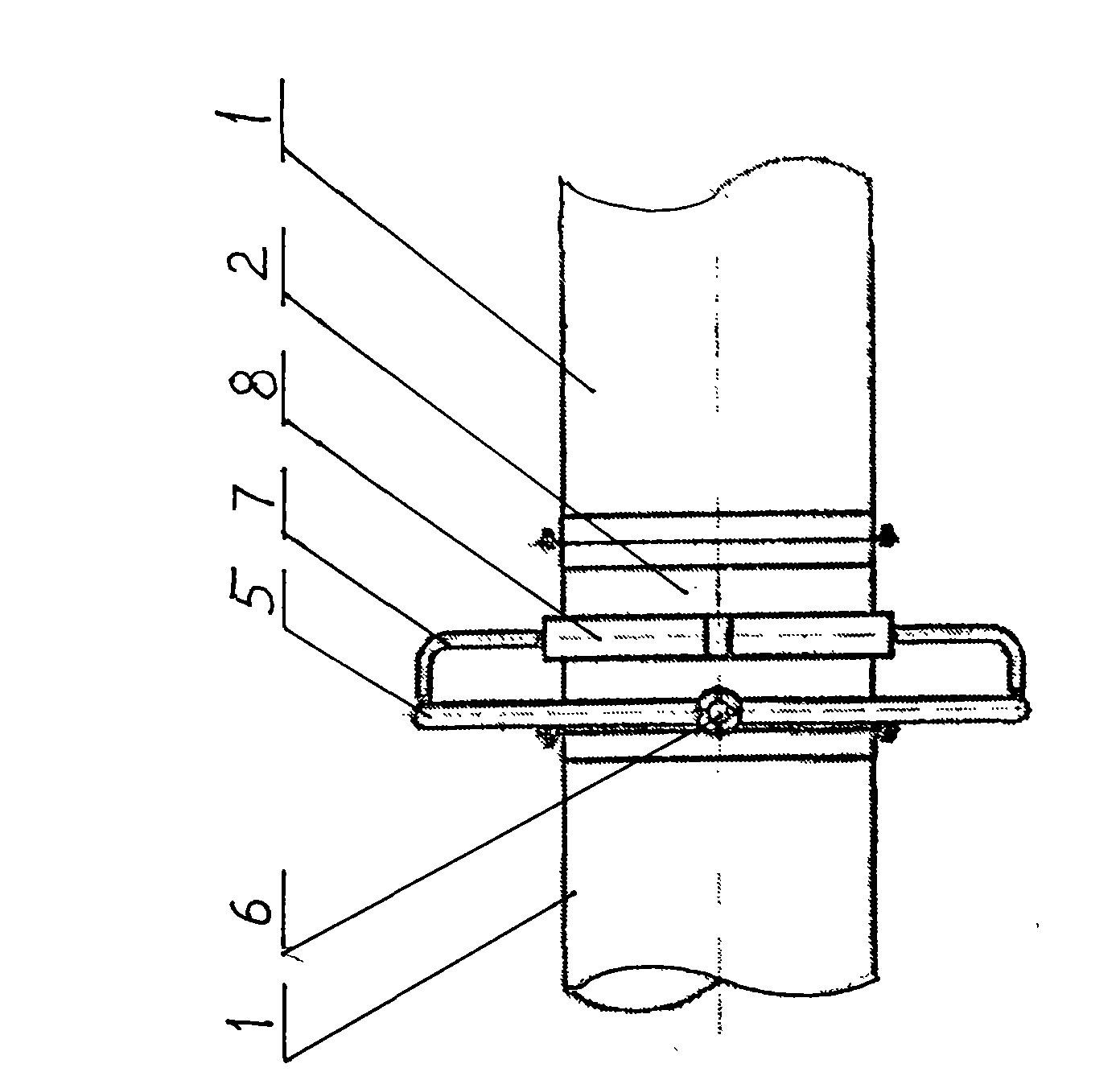

[0038] Referring to the accompanying drawings, the present invention completely abandons the grinding process of the ball mill, and directly installs a pipeline airflow crushing device in series on the way of fly ash transportation, that is, in a certain section of the original fly ash airflow conveying pipeline. The high-speed airflow makes the fly ash collide with each other at a high speed to realize the ultra-fine crushing of the fly ash during the transportation. The pipeline airflow crushing device 2 is the core component of the fly ash airflow conveying pipeline to realize the airflow crushing process. It is mainly composed of compressed air inlet , O-ring pipe, radial branch pipe, spray gun ring, nozzle, connecting flange, and bracket. The air compressor produces compressed gas with a pressure of 0.6-0.8Mpa, which enters the pipeline airflow crushing device, and then passes through the O-ring pipe. And the radial branch pipe enters the spray gun ring, and finally sprays...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com