Producing method of polycrystalline diamond complex valve base of pressure reducing valve

A technology of polycrystalline diamond and manufacturing method, which is applied in the field of preparation of wear-resistant and anti-erosion pressure reducing valve seat composite materials, can solve the problems of valve core wear and failure, achieve improved wear resistance, promote bonding, The effect of curbing abnormal growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

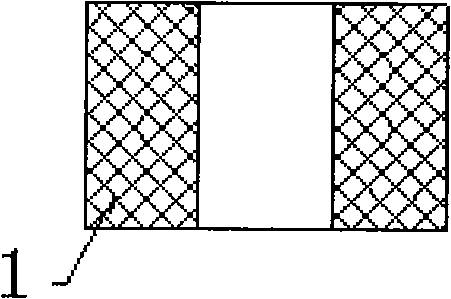

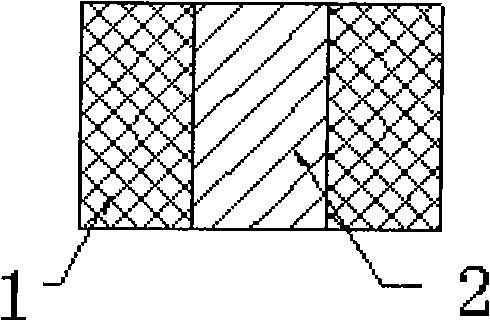

Embodiment 1

[0031] The diamond powder is a diamond micropowder with a complete crystal form, and its particle size ratio is W20:W10:W5=75:20:5. Before sintering, firstly weigh the raw diamond powder and carry out vacuum treatment to remove the suspended gas adsorbed on the surface of the diamond powder. The vacuum purification treatment conditions are: (1~3)×10 -3 Pa, 600°C, vacuum purification for 1h. Add 1-5wt% Fe powder and Si powder as sintering aids to the purified diamond micropowder, mix well, and pack the cemented carbide YG20 processed into a cylindrical structure into a metal molybdenum cup, tungsten (W)-cobalt ( Co)-like cemented carbide matrix structure such as figure 1 As shown, the cylinder 1 is filled with diamond mixture, and then assembled in the pyrophyllite cavity. Place the assembled pyrophyllite cavity on the domestic six-sided top ultra-high pressure and high temperature equipment, adopt the sintering process of first increasing the pressure to 6.0GPa and then incr...

Embodiment 2

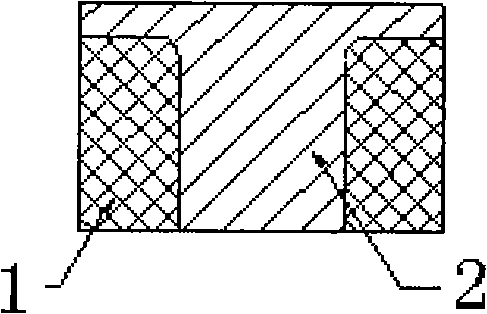

[0034] The diamond powder is a diamond micropowder with a complete crystal form, and its particle size ratio is W20:W10:W5=75:20:5. Before sintering, firstly weigh the raw diamond powder and carry out vacuum treatment to remove the suspended gas adsorbed on the surface of the diamond powder. The vacuum purification treatment conditions are: (1~3)×10 -3Pa, 600°C, vacuum purification for 1h. Add 1-5wt% Fe powder and Si powder as sintering aids to the purified diamond micropowder, mix evenly, put the hard alloy YG20 processed into a cylindrical structure into a metal molybdenum cup, and then put the cylinder 1 The inside and one end face are filled with diamond mixture, and then assembled in the pyrophyllite cavity. Place the assembled pyrophyllite cavity on the domestic six-sided top ultra-high pressure and high temperature equipment, adopt the sintering process of first increasing the pressure (6.0GPa) and then increasing the temperature. When the temperature rises to 1450°C, ...

Embodiment 3

[0038] A method for manufacturing a valve seat of a polycrystalline diamond composite pressure reducing valve, using tungsten (W)-cobalt (Co) hard alloy YG11 as a substrate, filling and mixing 1wt% sintering aids Fe powder and Si on the substrate powdered diamond powder. The purpose of adding sintering aid is to fully consider the difference in expansion coefficient between cemented carbide and diamond, to reduce the existence of liquid phase during PCD sintering as much as possible, to curb the abnormal growth of grains, and to avoid the sintering between the two after cooling. Cracks occur at the interface, reducing the service life of the valve seat. Diamond powder is a diamond powder with complete crystal form, and its particle size ratio is W20:W10:W5=70:25:5. Before sintering, first weigh the raw diamond powder with a good ratio, put it into a vacuum purification device, and purify it. treatment to remove the suspended gas adsorbed on the surface of the diamond micropow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com