Structure of vertical three-dimensional combined packaging of micro electric mechanical system and manufacture method thereof

A micro-electromechanical system and manufacturing method technology, applied in micro-structure technology, micro-structure devices, processing micro-structure devices and other directions, can solve the problems of poor assembly accuracy, difficult monitoring, low yield and reliability, etc., to avoid design and The difficulty of production, the reduction of packaging costs, and the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to fully demonstrate the advantages and positive effects of the present invention, the substantive features and remarkable progress of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

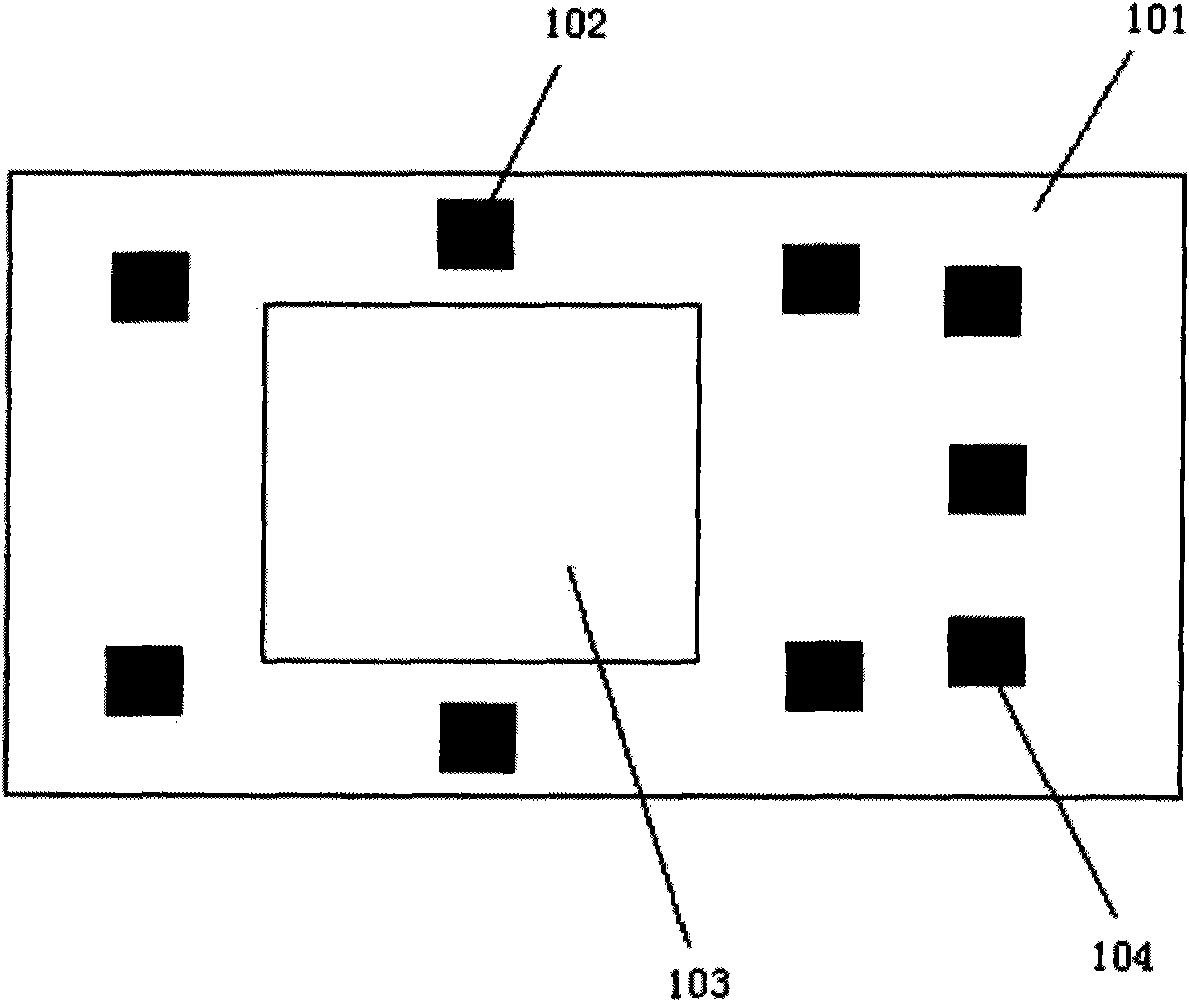

[0042] exist figure 1 Among them, on the substrate 101, mount the MEMS acceleration sensor 103, for the transmission of electrical signals, the MEMS device has six metal pads 102 and three pads 104 for vertical module signal transmission on the substrate 101.

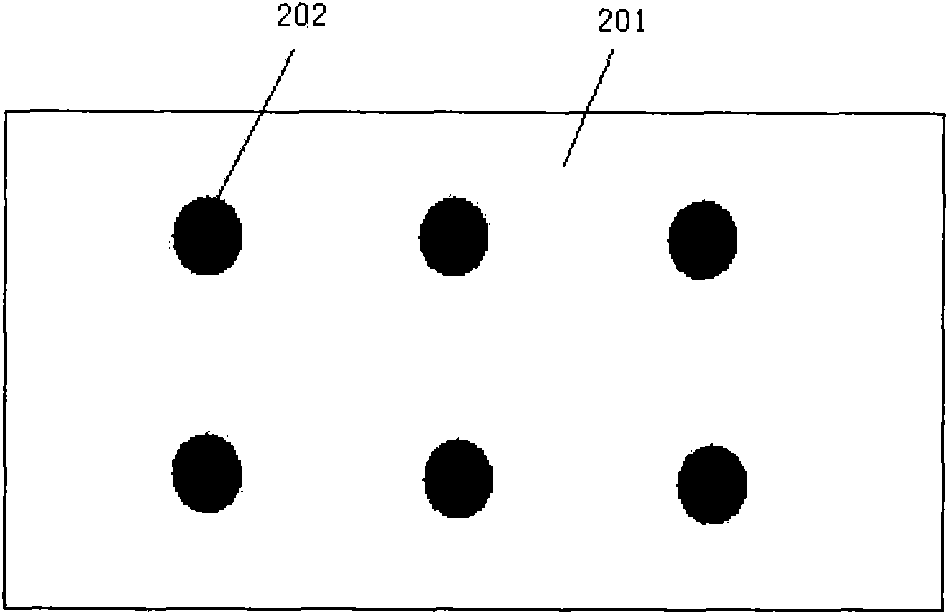

[0043] exist figure 2 , on the back surface 201 of the substrate, there are n×m pads 202 . (n and m are variable, depending on the number of external interfaces of the acceleration chip. If there are many signals to be connected, then n×m is large, and vice versa)

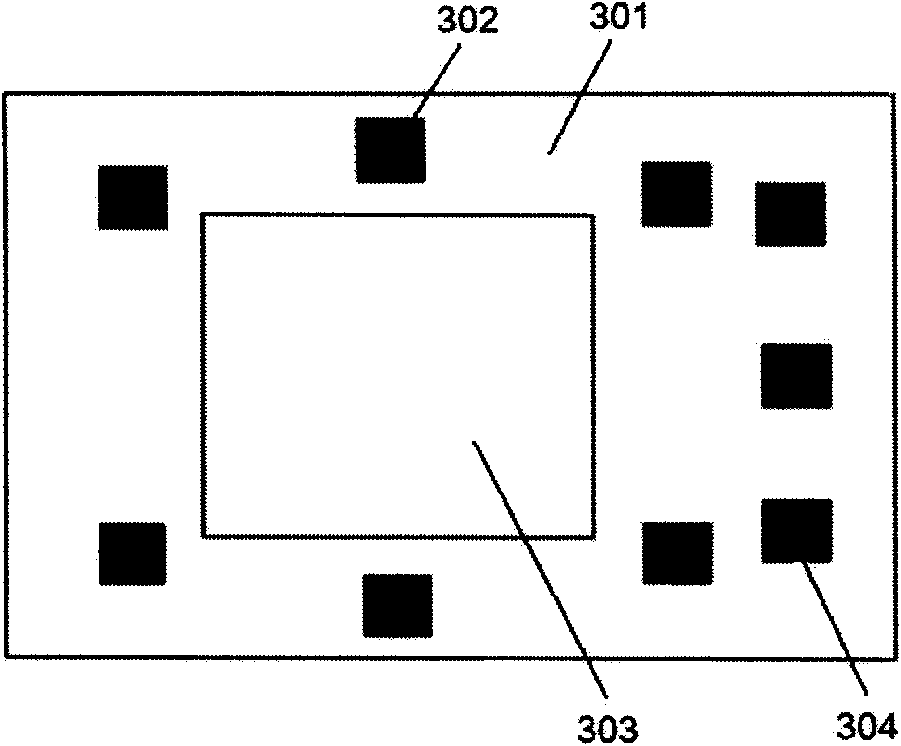

[0044] exist image 3 Among them, on a substrate 301, a MEMS sensor 303 is mounted. For the transmission of electrical signals, the MEMS device has six metal pads 302 and three pads 304 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com