Preparation method of nano calcium carbonate

A technology of nano-calcium carbonate and calcium oxide, applied in the field of nano-materials, can solve the problems of high quality requirements, unstable performance, and high process cost of quicklime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

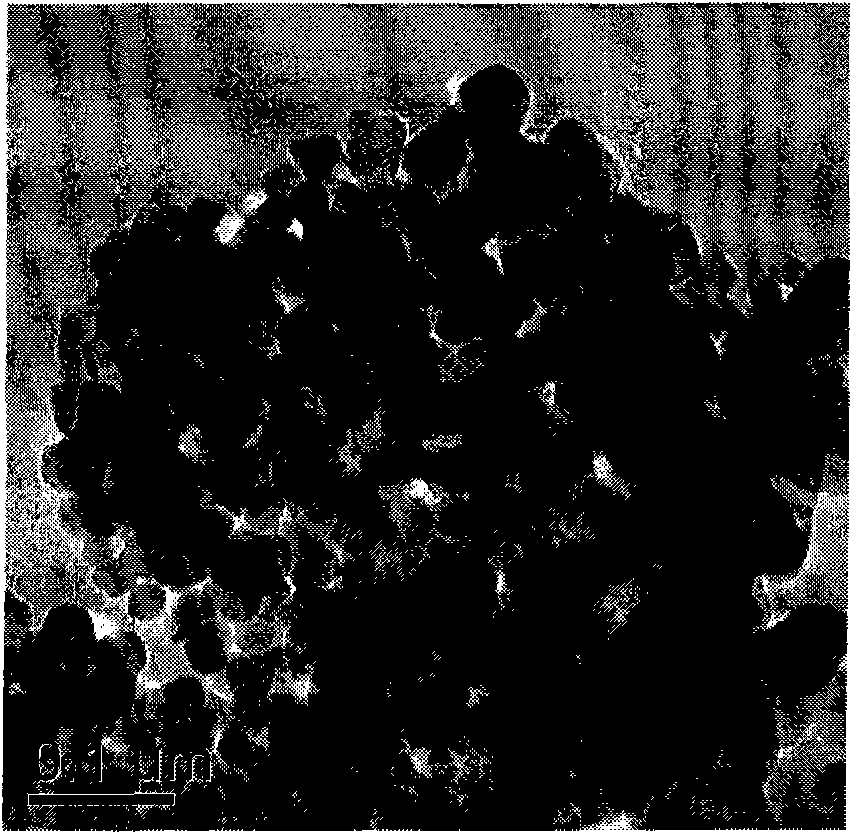

[0012] First add a certain amount of industrial calcium oxide generated after calcination into hot water at 60°C and stir at a constant temperature to generate Ca(OH) 2 Suspension, the mass ratio of industrial calcium oxide to water is 6 / 100, sieve through 200 mesh to remove slag, age, take 5L of the above suspension, control the concentration to 5%, add 0.1mol of crystal form control agent under stirring 60mL of sulfuric acid per L, in the above suspension, pass into the mixed gas of carbon dioxide and air with a volume content of carbon dioxide of 30%, and carry out carbonization reaction. Add 5.3 g of sodium pyrophosphate as a dispersant, stop the reaction when the pH of the suspension drops to 6.8, filter, and dry at 60° C. to obtain spherical nano-calcium carbonate with an average particle size of 40 nm. figure 1 Shown is a TEM photograph of the product.

Embodiment 2

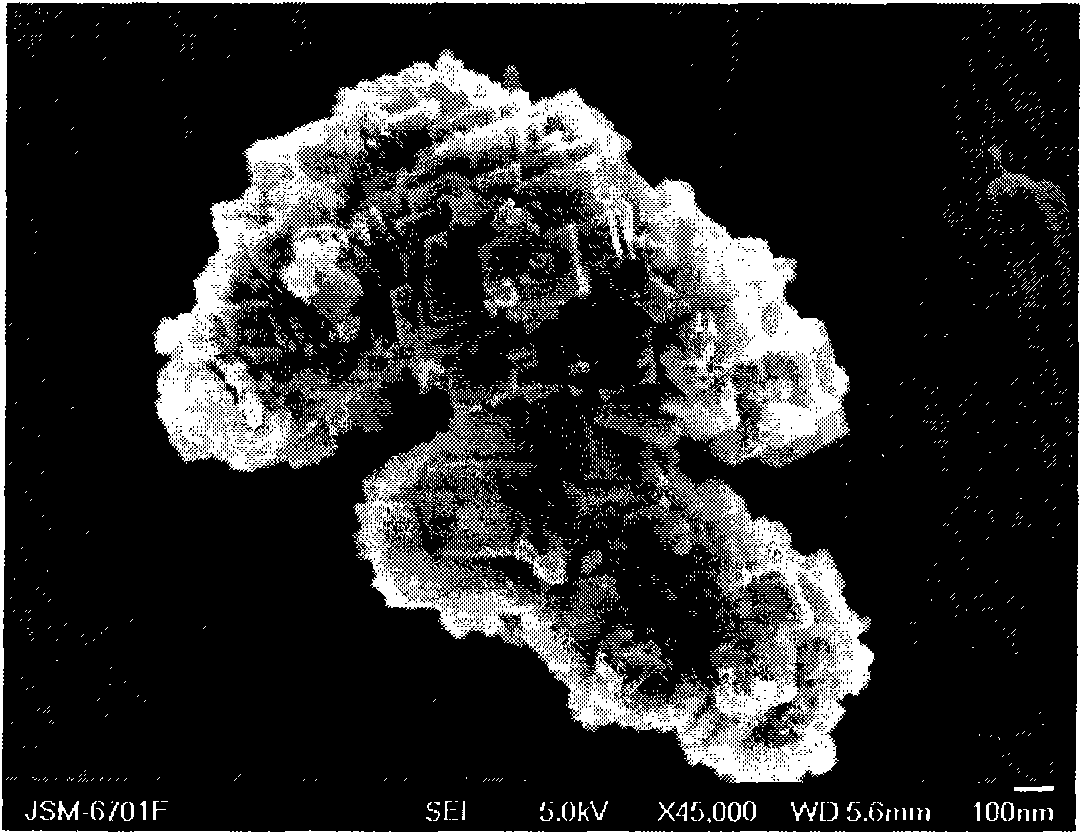

[0014] First add a certain amount of industrial calcium oxide generated after calcination into hot water at 70°C and stir at constant temperature to generate Ca(OH) 2 Suspension, the mass ratio of industrial calcium oxide to water is 7 / 100, sieved through a 250-mesh sieve to remove slag and age, take 5L of the above-mentioned suspension, control the concentration to 8%, and mix it under stirring Add 7 g of sodium hexametaphosphate, a crystal form control agent, and pass a mixed gas of carbon dioxide and air with a carbon dioxide volume content of 30% into the above solution phase to carry out carbonization reaction. The temperature of the carbonization reaction is controlled at 15°C; the stirring speed is 400r / min, and the dispersant sodium dodecylbenzenesulfonate 8g is added during the reaction, and the reaction is stopped when the pH of the suspension drops to 7.0, filtered, and heated at 70°C Needle-shaped nano-calcium carbonate particles can be obtained by drying, the leng...

Embodiment 3

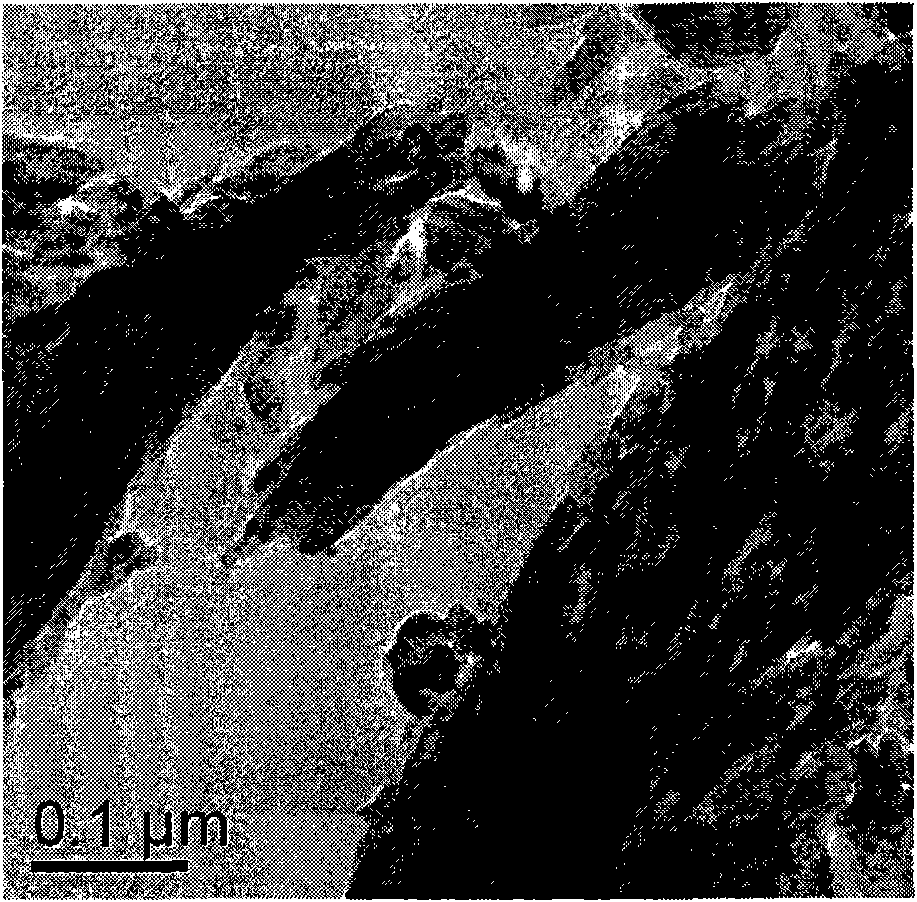

[0016] First add a certain amount of industrial calcium oxide generated after calcination into hot water at 70°C and stir at constant temperature to generate Ca(OH) 2 Suspension, the mass ratio of industrial calcium oxide to water is 8 / 100, sieved through a 300-mesh sieve to remove slag and age, take 5L of the above-mentioned suspension, control the concentration to 6%, and mix it under stirring Add 2.6 g of crystal form control agent sodium pyrophosphate, pass into the above-mentioned suspension a mixed gas of carbon dioxide and air with a carbon dioxide volume content of 30%, and carry out carbonization reaction. The temperature of the carbonization reaction is controlled at 16° C., and the stirring speed is 500 r / min , add 11g of dispersant sodium dodecylsulfonate during the reaction, stop the reaction when the pH of the suspension drops to 7.0, filter, and dry at 60°C to obtain flaky nano-calcium carbonate particles, such as figure 2 As shown, the average size of the shee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com