Polytrimethylene terephthalate/Poly-butylene terephthalate alloy material and preparation method thereof

A technology of polytrimethylene terephthalate and polybutylene terephthalate, applied in the field of polytrimethylene terephthalate/polybutylene terephthalate alloy material and its preparation, can solve the problem of Reduce material heat distortion temperature, rigid flexural modulus, deterioration of processability of polytrimethylene terephthalate, and no modified materials, etc., to achieve the effect of improving rigidity, good processability, and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

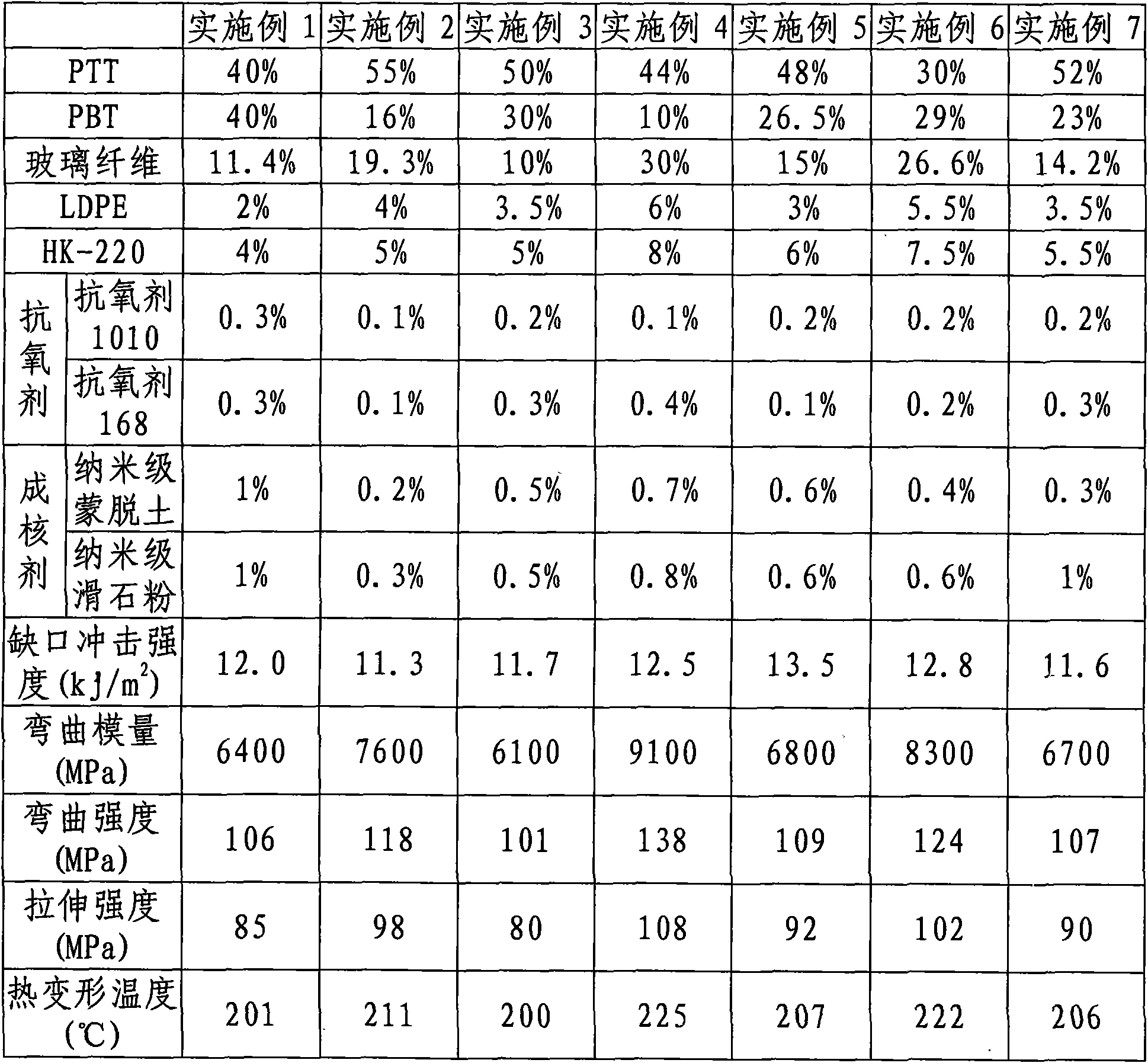

Examples

Embodiment 1

[0032] The polytrimethylene terephthalate / polybutylene terephthalate alloy material of the present invention comprises polytrimethylene terephthalate (PTT), polybutylene terephthalate (PBT), glass fiber, Low density polyethylene (LDPE), compatibilizer, antioxidant and nucleating agent. Among them, the relative density of polytrimethylene terephthalate (PTT) is 1.34-1.37; the melting point is 220-230 ° C, and the melt viscosity is between 0.85-0.90; the polybutylene terephthalate (PBT) The relative density is 1.33-1.36; the melting point is 225-235°C, and the melt viscosity is between 0.8-1.2; the glass fiber is alkali-free, untwisted, 10 yarns / 20 strands of long fiber; low-density polyethylene (LDPE) The melt index (230°C, 2.16kg) is 30-60; the compatibilizer is acrylate and glycidyl ester bifunctional vinyl elastomer (HK-220), and its melt index (230°C, 5kg) is 1.0 -2.0, graft rate 0.5-1.5%; Antioxidant is tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaeryt...

Embodiment 2

[0040] The polytrimethylene terephthalate / polybutylene terephthalate alloy material of the present invention comprises polytrimethylene terephthalate (PTT), polybutylene terephthalate (PBT), glass fiber, Low density polyethylene (LDPE), compatibilizer, antioxidant and nucleating agent. Among them, the relative density of polytrimethylene terephthalate (PTT) is 1.34-1.37; the melting point is 220-230 ° C, and the melt viscosity is between 0.85-0.90; the polybutylene terephthalate (PBT) The relative density is 1.33-1.36; the melting point is 225-235°C, and the melt viscosity is between 0.8-1.2; the glass fiber is alkali-free, untwisted, 10 yarns / 20 strands of long fiber; low-density polyethylene (LDPE) The melt index (230°C, 2.16kg) is 30-60; the compatibilizer is acrylate and glycidyl ester bifunctional vinyl elastomer (HK-220), and its melt index (230°C, 5kg) is 1.0 -2.0, graft rate 0.5-1.5%; Antioxidant is tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaeryt...

Embodiment 3

[0048] The polytrimethylene terephthalate / polybutylene terephthalate alloy material of the present invention comprises polytrimethylene terephthalate (PTT), polybutylene terephthalate (PBT), glass fiber, Low density polyethylene (LDPE), compatibilizer, antioxidant and nucleating agent. Among them, the relative density of polytrimethylene terephthalate (PTT) is 1.34-1.37; the melting point is 220-230 ° C, and the melt viscosity is between 0.85-0.90; the polybutylene terephthalate (PBT) The relative density is 1.33-1.36; the melting point is 225-235°C, and the melt viscosity is between 0.8-1.2; the glass fiber is alkali-free, untwisted, 10 yarns / 20 strands of long fiber; low-density polyethylene (LDPE) The melt index (230°C, 2.16kg) is 30-60; the compatibilizer is acrylate and glycidyl ester bifunctional vinyl elastomer (HK-220), and its melt index (230°C, 5kg) is 1.0 -2.0, graft rate 0.5-1.5%; Antioxidant is tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaeryt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com