Vertical cylinder piston type internal combustion engine

A technology for vertical cylinders and internal combustion engines, applied to cylinders, cylinder heads, mechanical equipment, etc., can solve problems such as manufacturing difficulties, hindering promotion value, and large size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

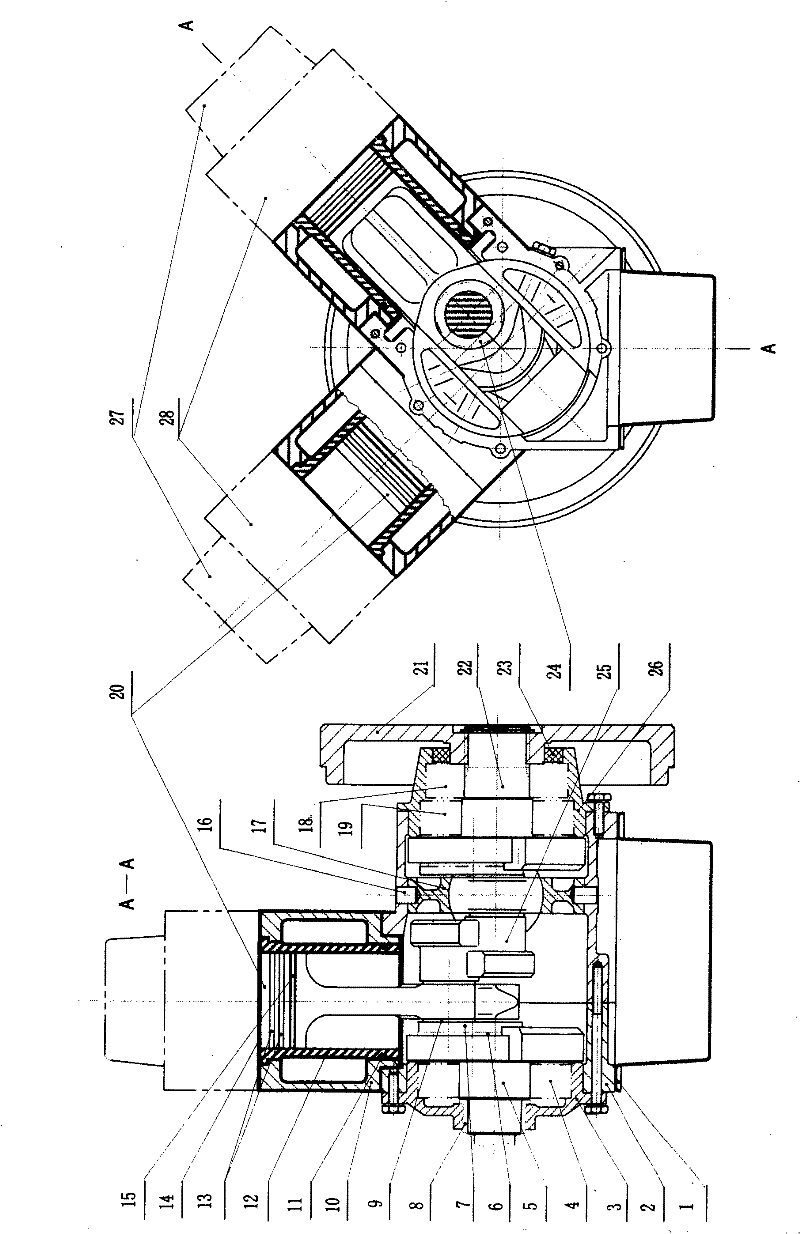

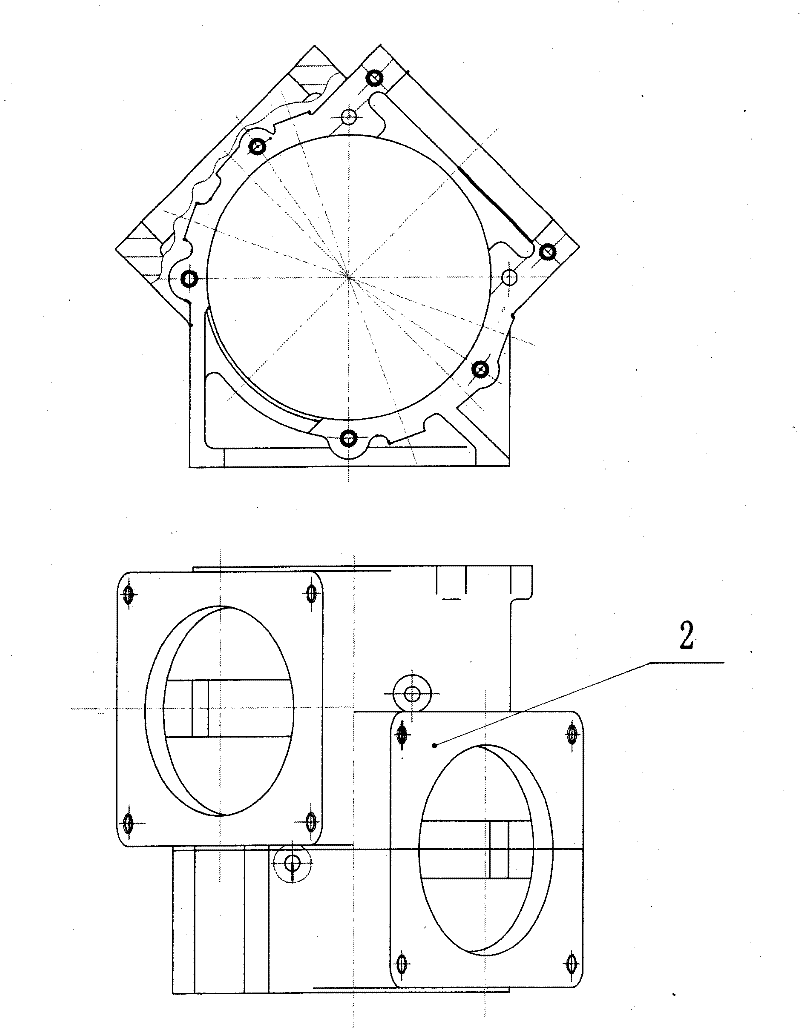

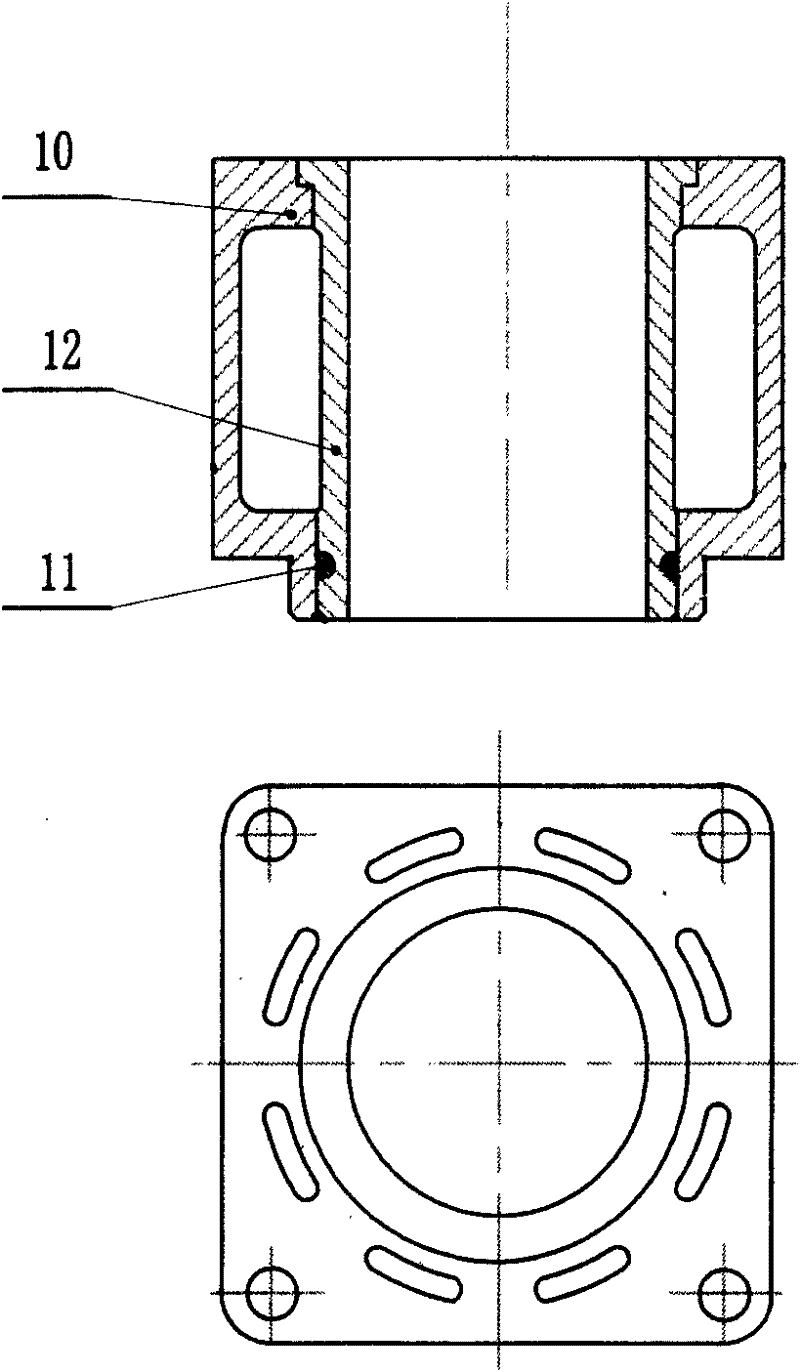

Embodiment 1

[0059] Embodiment 1, double cylinder machine, such as figure 1. The machine body (2) needs to be cast separately, and after semi-finishing, it needs to be finished in one piece. Finally, it is combined with the cylinder, cylinder block and support block for boring and honing. After all parts are processed, they must be inspected. Cover and oil seal, front crank shaft, bearing, front cover and other parts are assembled into assemblies. Remove the right cylinder and cylinder block. Separate the body and the front support block, and then put the left cylinder into the piston group. Put one journal of the eccentric shaft into the piston bearing, then put the right cylinder piston group together with the support block into the machine body and the other journal of the eccentric shaft, put back the separated part of the machine body, and put the right cylinder and the cylinder block into the Piston and body; install gaskets into the eccentric journals at the front and rear ends, ...

Embodiment 2

[0060] Embodiment 2, multi-cylinder machine, such as Figure 12 . The casting, parts processing and assembly process of the machine body are similar to the above, and will not be repeated here. Only the differences of the multi-cylinder machine are explained as follows:

[0061] 1. The machine body should be divided into three parts and cast separately, and then assembled together after semi-finishing. After finishing, it should be combined with the cylinder, cylinder block and support block for cylinder boring and honing, and then disassembled during assembly.

[0062] 2. When assembling, install the intermediate crankshaft and bearing first, then fit the two eccentrics in the eccentric hole of the intermediate crankshaft, then install the piston components in the front and rear cylinders, install the eccentric shaft into the piston bearing, and put the pad on it piece, and then put it into the eccentric sleeve, the rest is the same as the above, except that 2 more cylinders...

Embodiment 3

[0064] Embodiment 3, two-way acting piston machine, as Figure 14 . The body and piston of this kind of internal combustion engine are more complicated than those mentioned above, and the model and casting have to be done again. Boring cylinder and honing together, because there is no oil pan, and there are no holes around, so the necessary assembly holes have to be cast in advance, and then covered after assembly, and because the oil pan is installed between the body and the flywheel, it is necessary to The location and connection method are selected, and other matters are similar to the above.

[0065] If the eccentric shaft (25) adopts Figure 20 or 21 structure, the eccentric sleeve (7) adopts Figure 19 The structure of body (2) just needn't separate casting and finish machining, and cylinder, cylinder block, support block and body also needn't be folded after cylinder boring and honing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com