Floating body rope pulley wave energy generating system

A power generation system and wave energy technology, applied in ocean energy power generation, engine components, machines/engines, etc., can solve the problems of inability to absorb waves, small propulsion force, and poor wind and wave resistance, so as to increase effective working time, reduce Instantaneous impact force, enhanced effect of wind and wave resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

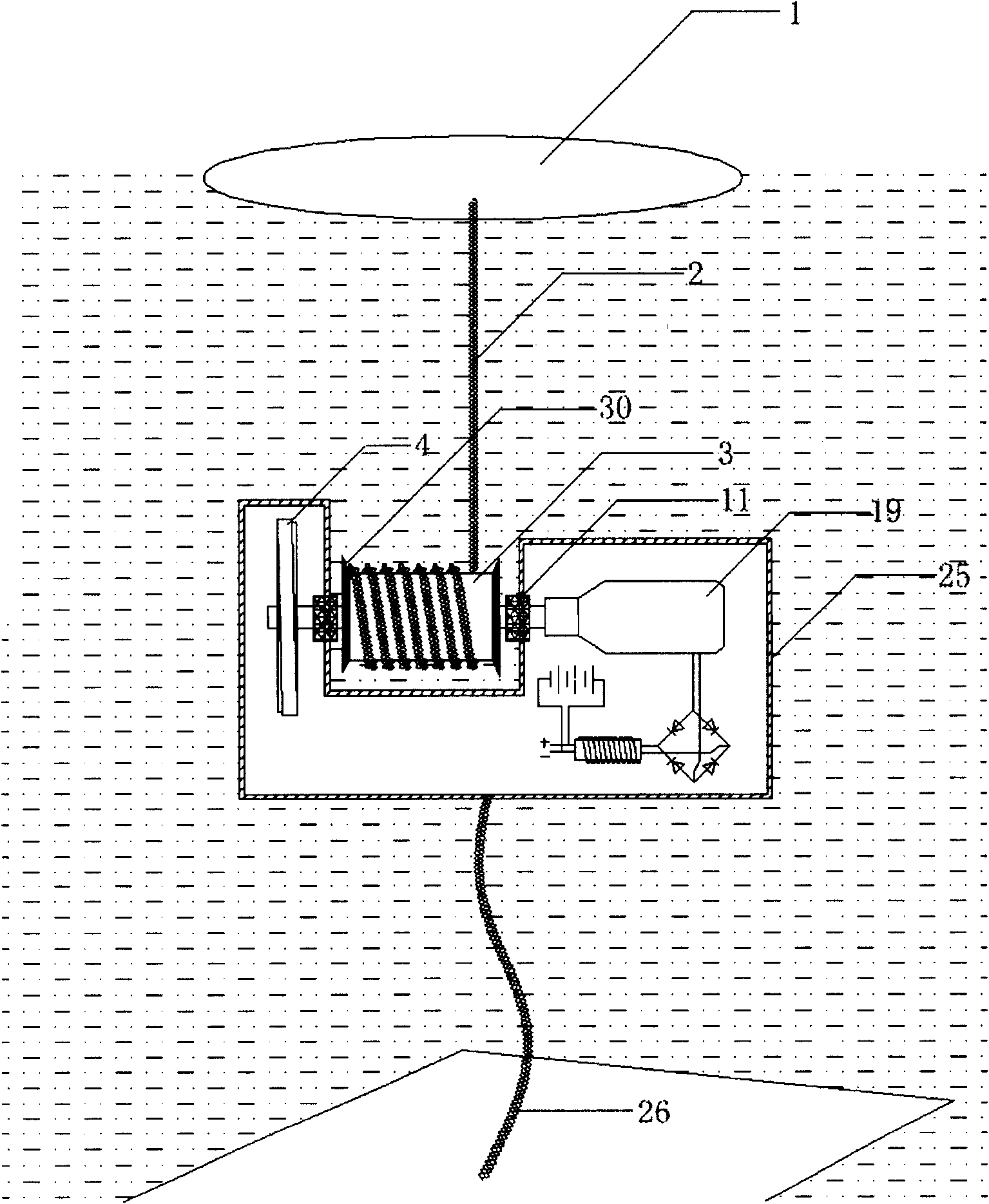

[0068] (1) For the power consumption of the navigation buoy, because it does not require too much energy, a simplified floating body rope pulley wave energy generation system can be used (see figure 1 ). Make the floating body (1) with the discus-shaped sea floater, and the specific size of the area depends on the energy demand, such as 1 meter in diameter and 0.3 meter in thickness. Rope (2) should adopt high-strength, corrosion-resistant, wear-resistant, smooth, good material of flexibility to make, such as nylon, and total length is about 50 meters and gets final product, and 25 meters are wound on the runner (3). Runner (3) is made of vinyl plastics, and baffle plate (30) is arranged at runner (3) two ends, and runner (3) diameter is 0.5 meter. The runner (3) is coupled with the volute spring (4), transmission or g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com