Vertical measuring system capable of adjusting zero-plane position

A measurement system and plane position technology, applied in the field of measurement systems, can solve the problems of inability to eliminate vertical measurement errors, non-adjustment, etc., and achieve the effects of simple structure, fast adjustment speed, and improved measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

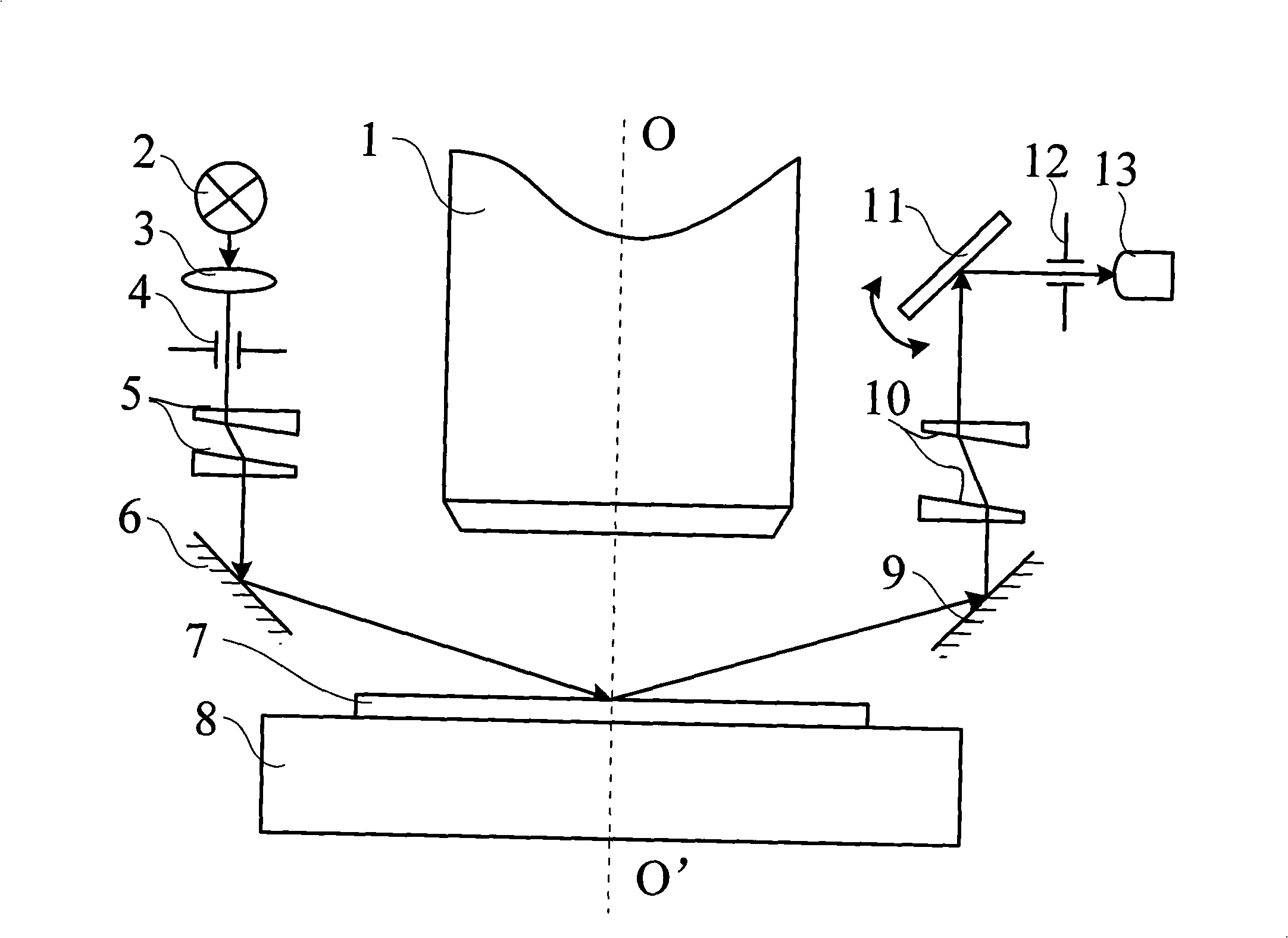

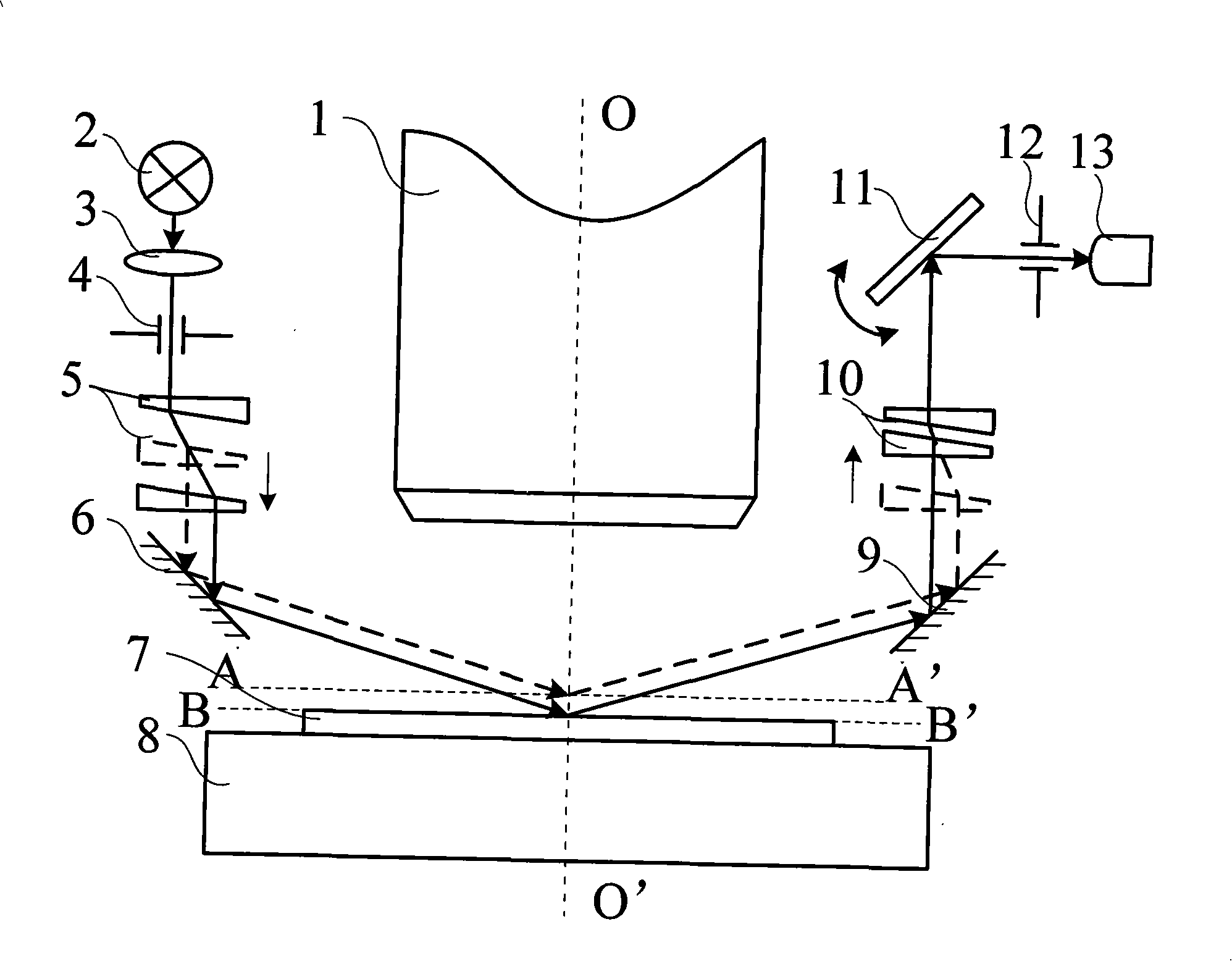

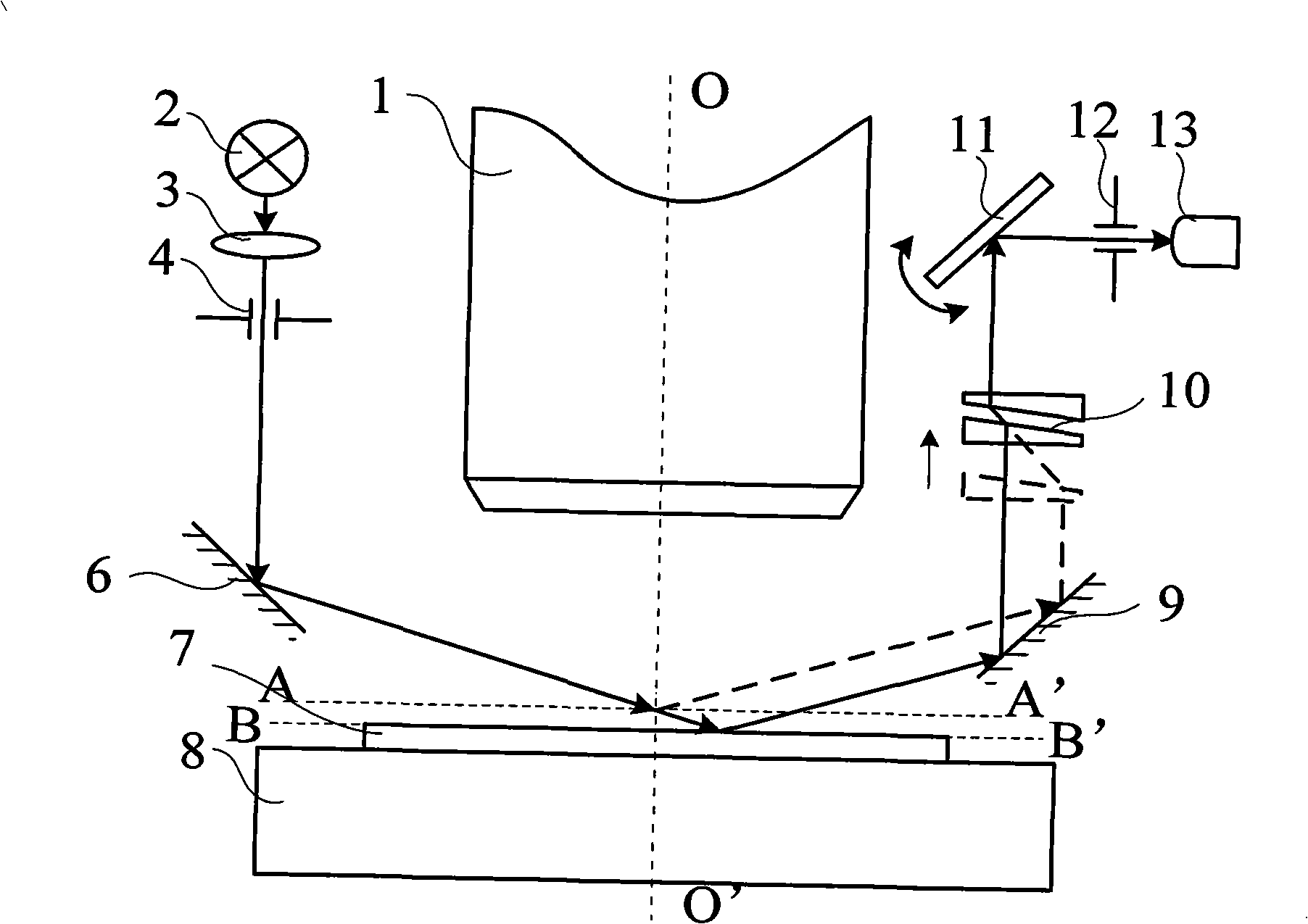

[0037] figure 1 It is a structural schematic diagram of the vertical measurement system in a preferred embodiment of the present invention.

[0038] This embodiment discloses a vertical measurement system that can automatically adjust the position of the zero plane, which can be used as a vertical measurement sensor for a photolithography machine. Such as figure 1 As shown, the vertical measurement system disclosed in this embodiment is suitable for lithography equipment.

[0039] The lithography equipment includes components such as a projection objective lens 1 and a workbench 8 . The measured silicon wafer 7 is placed on the workbench 8 . The workbench 8 can drive the silicon wafer 7 to move vertically and horizontally.

[0040] The vertical measurement system includes a light source 2, a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com