Method for preparing isocyanate

A technology of isocyanate and methyl dicarbamate, which is applied in the field of organic compound preparation, can solve the problems of difficult separation of products and intermediates, high content of isocyanate products, and low content of crude products, and achieve easy control of heating program and simple decompression operation , high product content and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

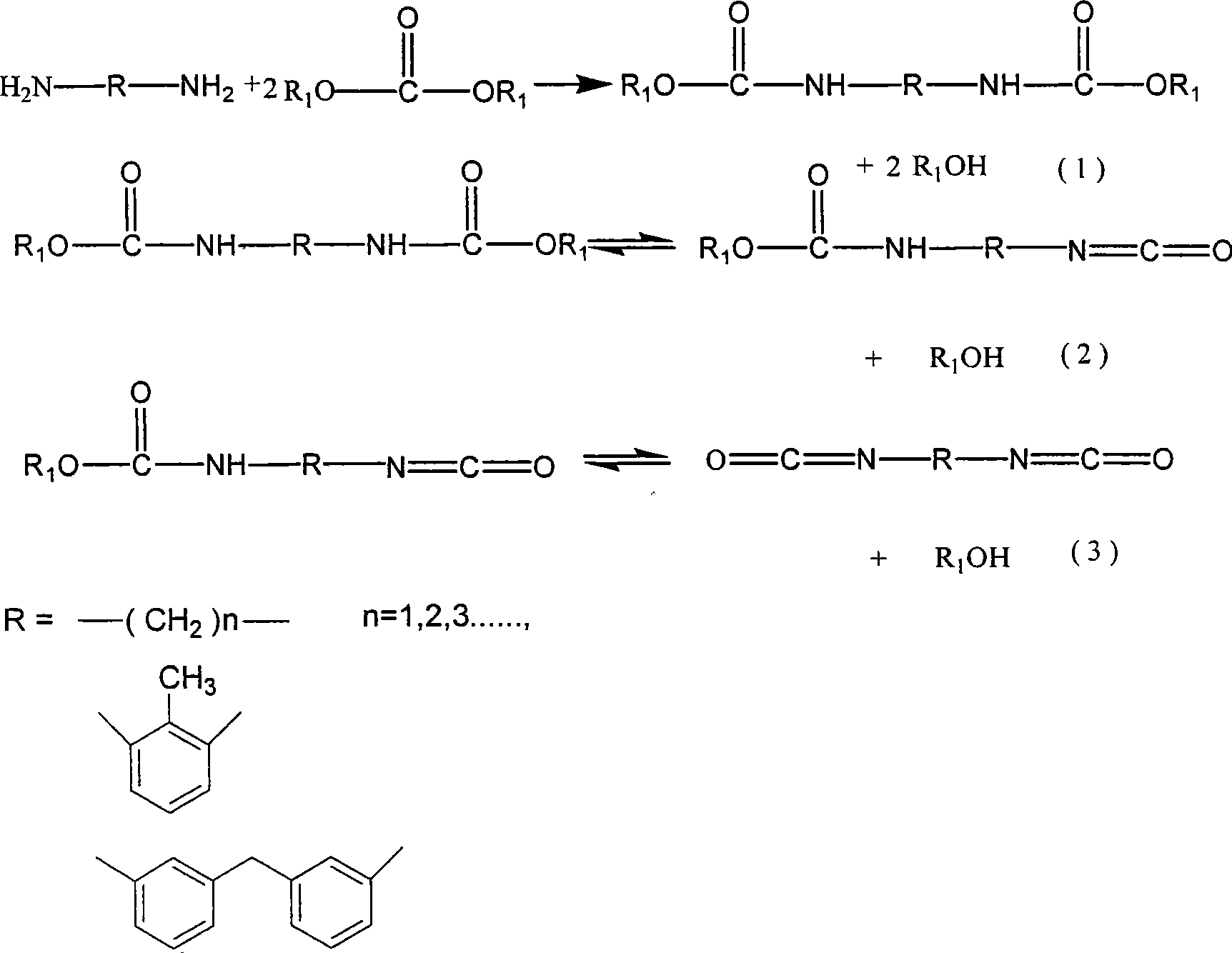

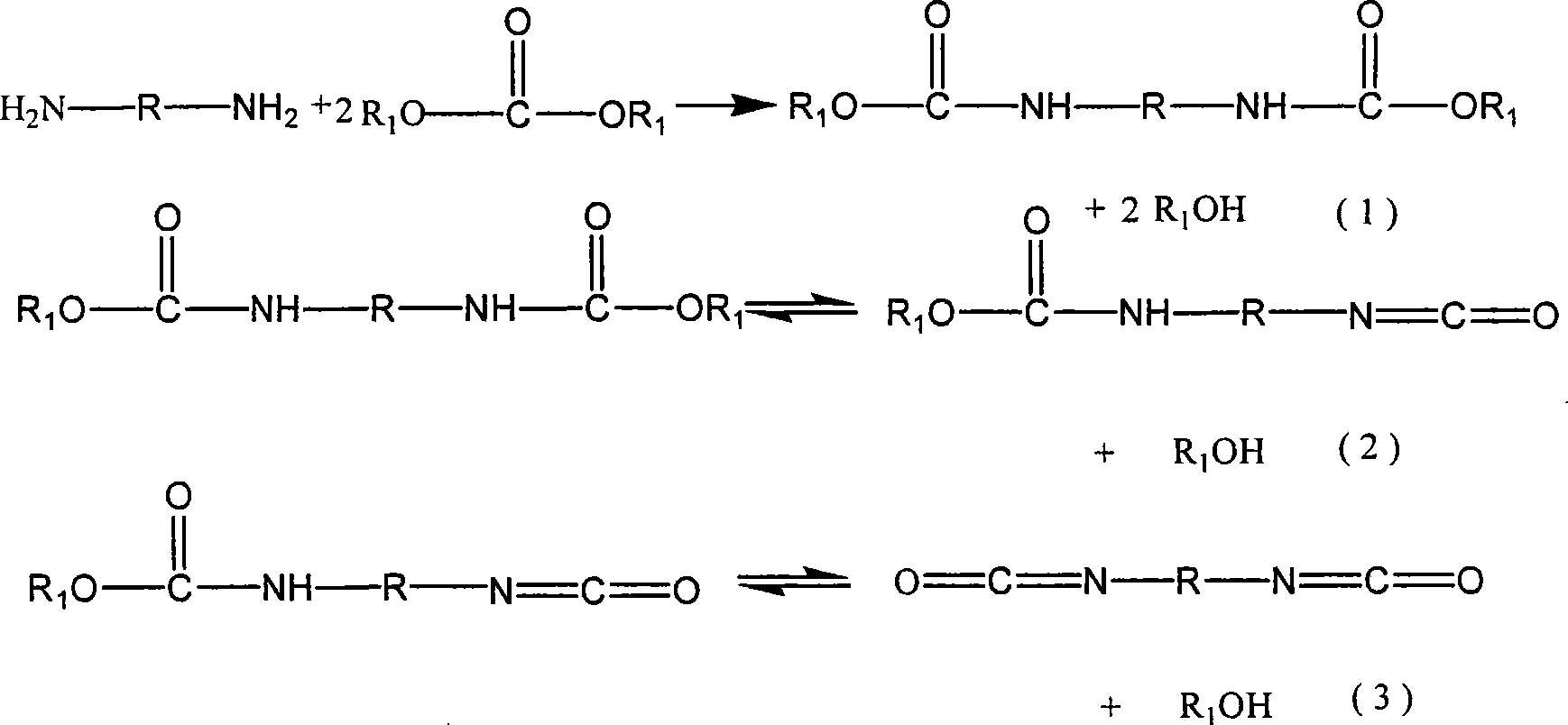

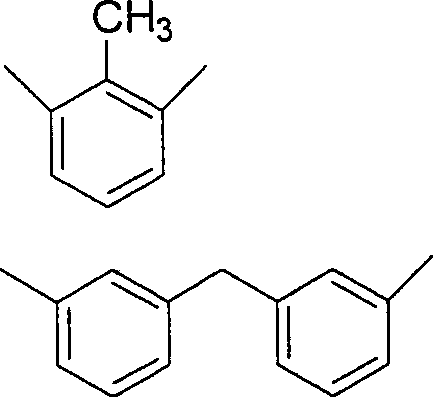

Method used

Image

Examples

Embodiment 1

[0016] Put 50g of hexamethylene 1,6-methyl dicarbamate (HDU), 100g of dioctyl phthalate and 2g of zinc-zinc oxide into the reaction kettle, and replace the air in the reaction system with nitrogen , enter the program operation, raise the reaction temperature to 220°C within 1 hour, and adjust the vacuum degree of the system to -0.090MPa; keep the conditions unchanged and pyrolyze for 1 hour, start to collect the product, and raise the temperature to within half an hour 240°C, under the premise of constant temperature, gradually adjust the vacuum degree of the system to -0.098MPa until the reaction is completed; the purity of the product is 89.8% and the yield is 90.5% according to gas chromatography analysis.

Embodiment 2

[0018] Add the heat carrier and the catalyst recovered after the reaction of Example 1 into the reactor, add 5% heat carrier of the heat carrier amount, then add 50g hexamethylene 1,6-dicarbamate methyl ester (HDU), replace with nitrogen After the air in the reaction system is exhausted, enter the program operation, raise the reaction temperature to 220°C within 1 hour, and adjust the vacuum degree of the system to -0.090MPa; keep the conditions unchanged and pyrolyze for 1 hour, start to collect the product, and in half Increase the temperature to 240°C within hours, and gradually adjust the vacuum degree of the system to -0.098MPa under the premise of constant temperature until the reaction is completed; the purity of the product is 89.0% and the yield is 90.1% according to gas chromatography analysis.

Embodiment 3

[0020] Add 100g of hexamethylene 1,6-methyl dicarbamate (HDU), 200g of dioctyl phthalate and 4g of zinc-zinc oxide into the reaction kettle, and replace the air in the reaction system with nitrogen , enter the program operation, raise the reaction temperature to 220°C within 1 hour, and adjust the vacuum degree of the system to -0.090MPa; keep the conditions unchanged and pyrolyze for 1.2 hours, start to collect the product, and raise the temperature to within 1 hour 250°C, under the premise of constant temperature, gradually adjust the vacuum degree of the system to -0.098MPa until the reaction is completed; the purity of the product is 88.8% and the yield is 92.5% according to gas chromatography analysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com