Method for hydrothermally synthesizing Alpha-iron oxide red nanocrystalline

A technology of ferric oxide and hydrothermal synthesis, which is applied in the direction of iron oxide, chemical instruments and methods, iron oxide/iron hydroxide, etc., to achieve the effect of simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

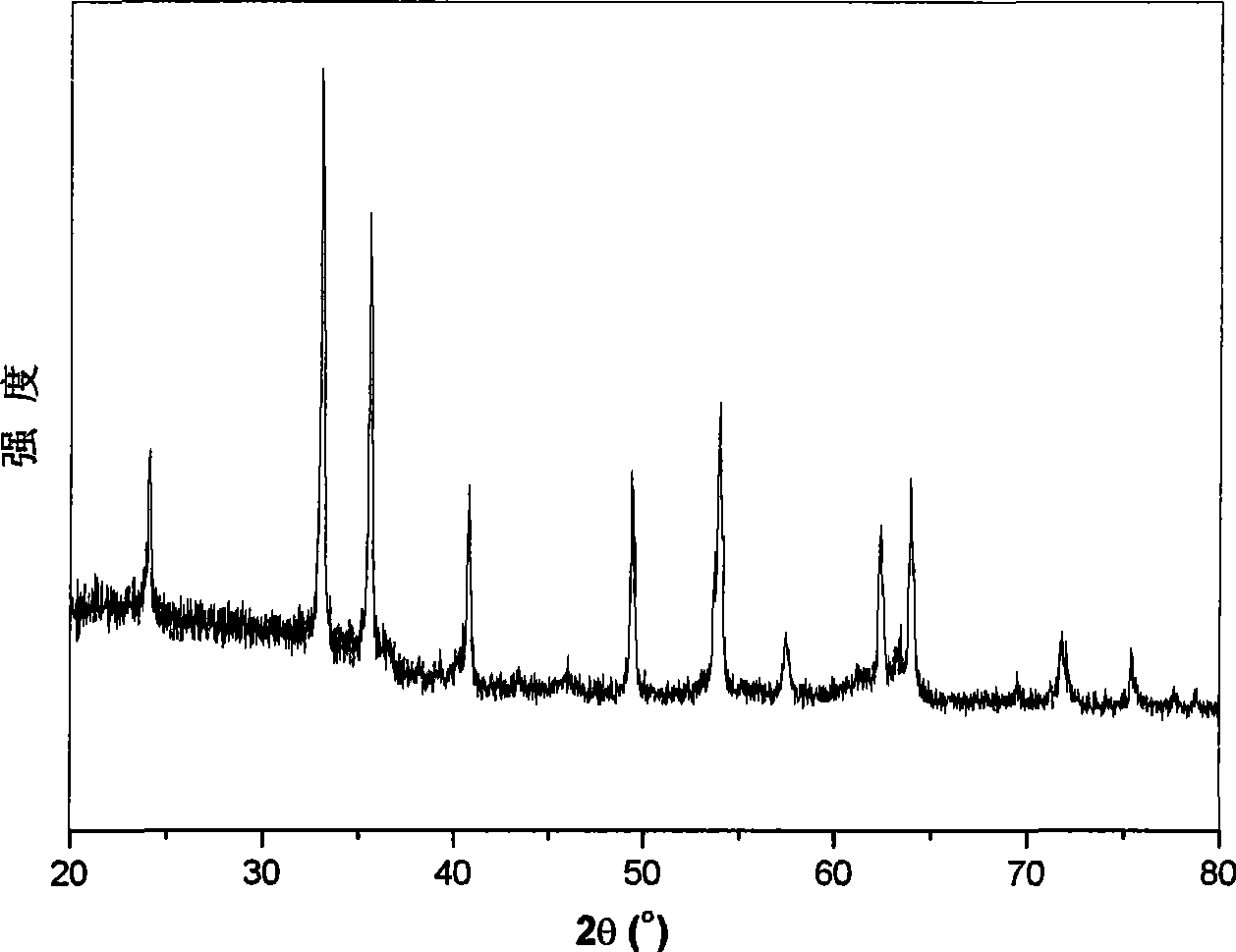

Image

Examples

Embodiment approach 1

[0011] Add 15mL distilled water into a 50mL beaker, add 1.06g potassium ferrocyanide under stirring, continue to stir until potassium ferrocyanide is completely dissolved, then add 5mL hydrogen peroxide, continue stirring for 10 minutes, then transfer the above solution to 50mL reaction In the kettle, it was crystallized at 140°C for 3 hours. After the reaction, the reaction kettle was naturally cooled to room temperature. The obtained red precipitate was washed with deionized water until neutral, and the obtained product was vacuum-dried at 120°C for 3 hours to obtain the final product.

Embodiment approach 2

[0013] Change the crystallization time in Embodiment 1 to 6 hours, and keep other conditions unchanged.

Embodiment approach 3

[0015] The crystallization time in Embodiment 1 was changed to 9 hours, and other conditions were unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com