Device for sealing and cleaning cable wires at well head

A cleaning device and steel wire rope technology, applied in the direction of cleaning equipment, sealing/packing, wellbore/well parts, etc., can solve the problems of unfavorable environmental protection, easy wear and replacement of packing, easy leakage, etc., and achieve excellent sealing and cleaning effect, The effect of reducing working hours and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

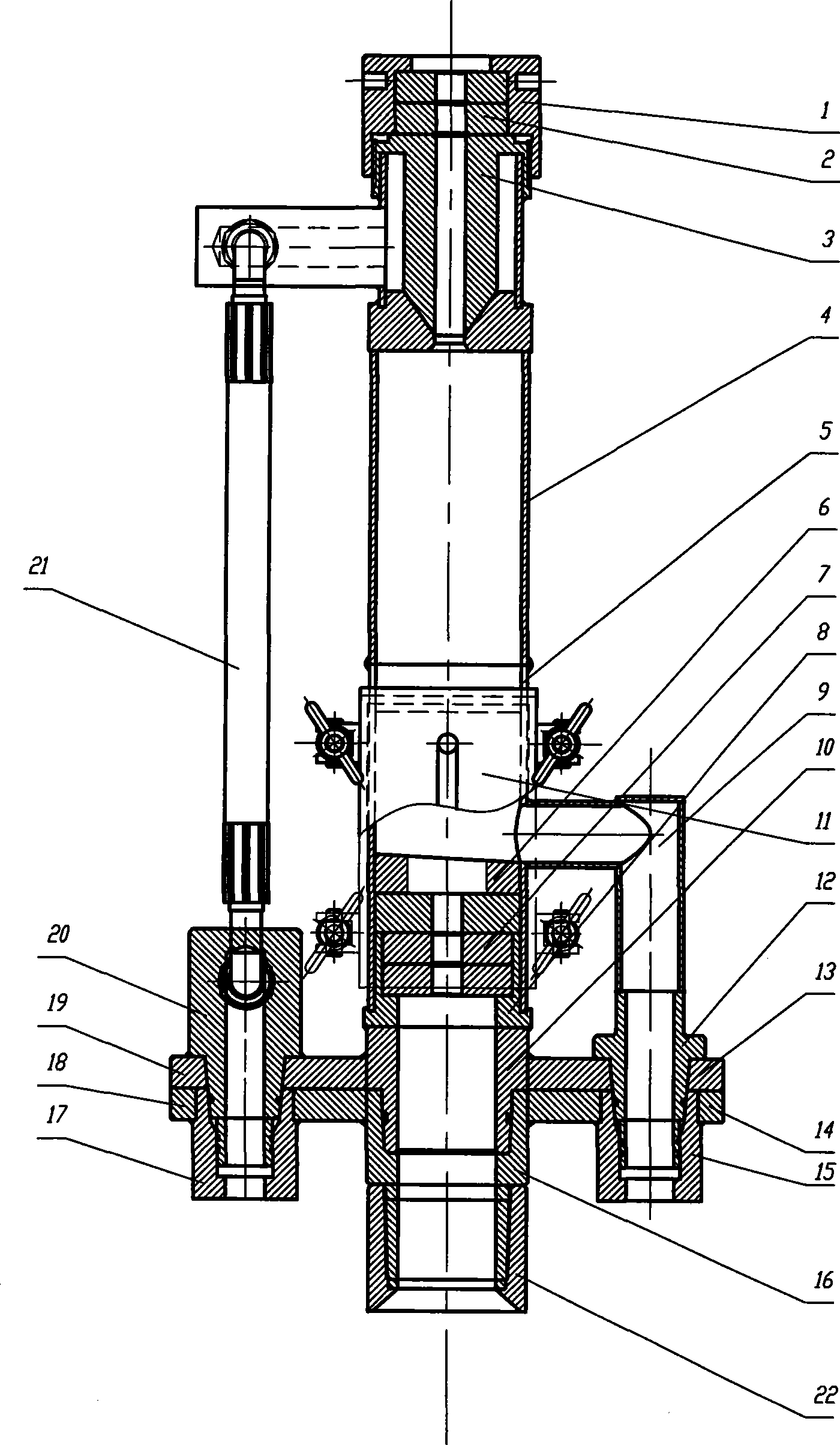

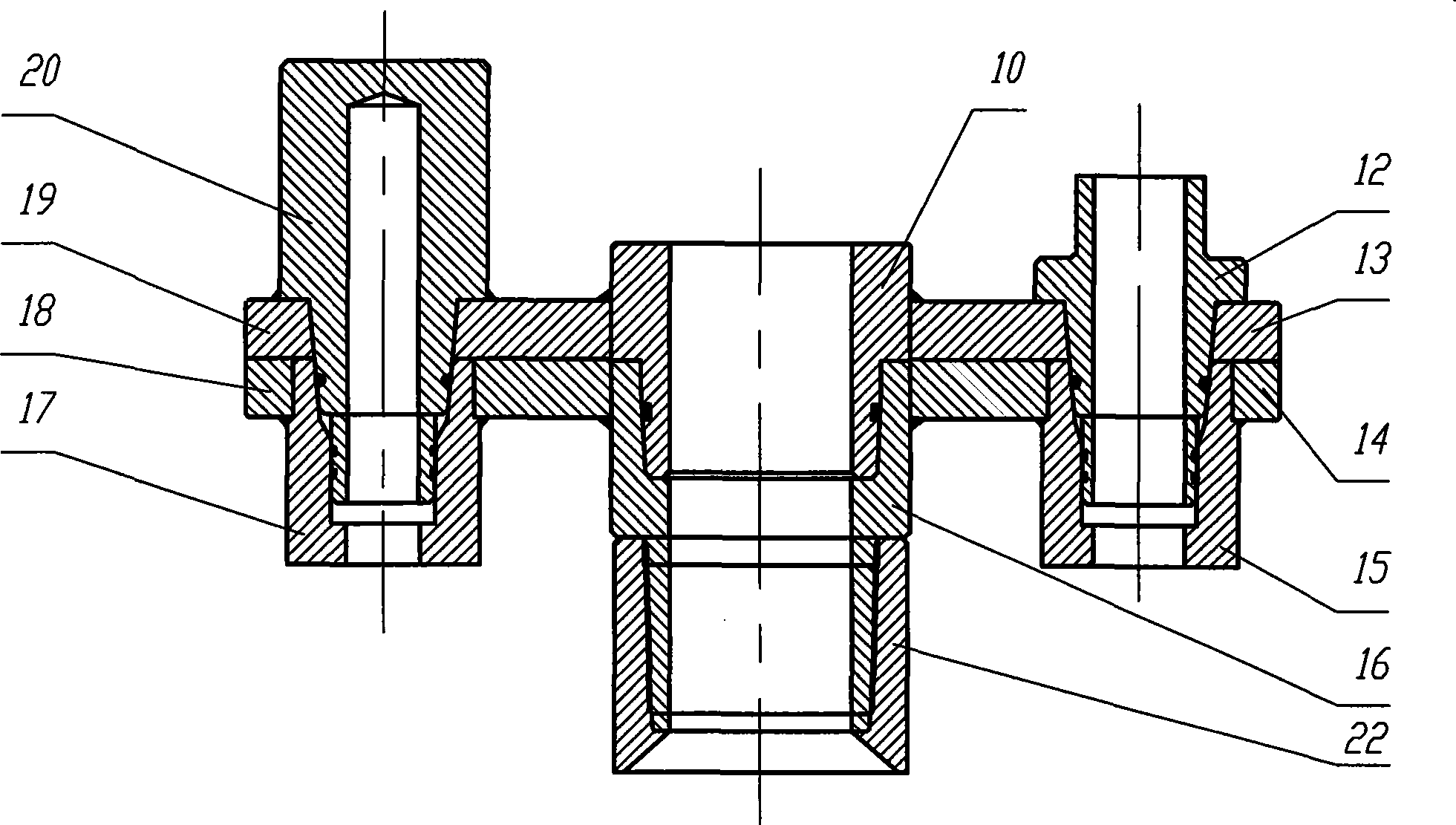

[0011] External working process: The upper and lower parts of the device can be separated, the upper and lower parts are connected by a conical fit structure, and the lower part is connected to the Figure 4 main oil drain. The main oil drainage device is connected to the wellhead. Firstly, the oil pumping wire rope is passed through the upper part of the device, and then the oil pump is installed. The upper part of the device is stuck on the oil pump. When it is necessary to replace the oil pump When the plunger is in operation, the upper part of the device rises with the wire rope. The trial oil production starts to transport the steel wire rope to the designated position downhole. When the steel wire rope is lifted upwards, the device starts to send air to clean up the oil stains carried by the steel wire rope from the downhole.

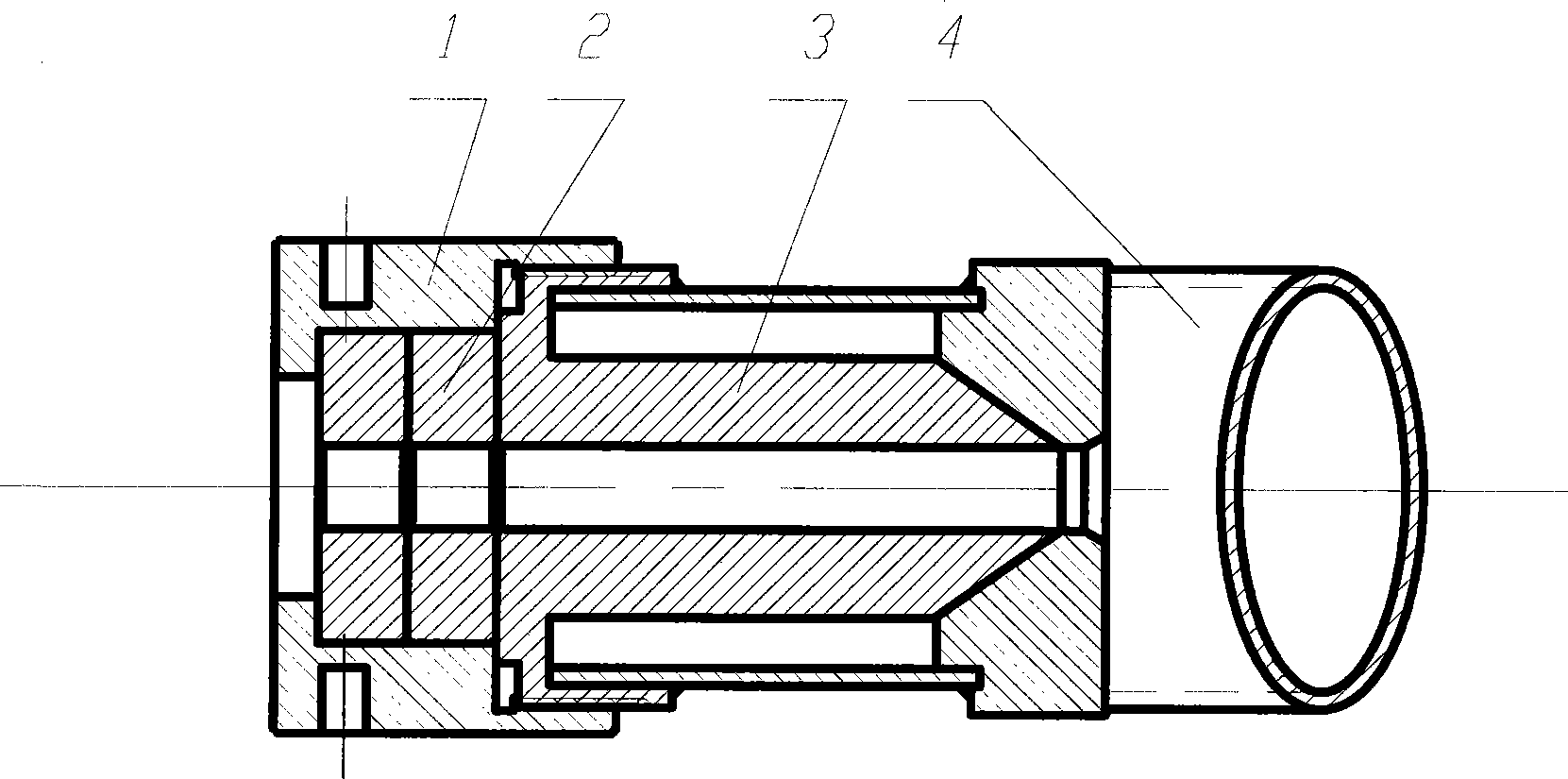

[0012] The working principle of this device: use compressed air as the cleaning medium, let the air flow enter the intake pipe of the device thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com