Diesel engine cylinder fuel-cut oil-saving system with twin-pressure charging system and pressure relief device

A technology of pressure relief device and supercharging system, which is applied in mechanical equipment, engine control, machine/engine, etc., can solve the influence of supercharger performance, compression work, pumping loss, influence on combustion of working cylinder and Thermal efficiency, affecting the reliability of the supercharger, etc., to improve the spray quality, ensure normal work and reliability, and reduce frictional resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

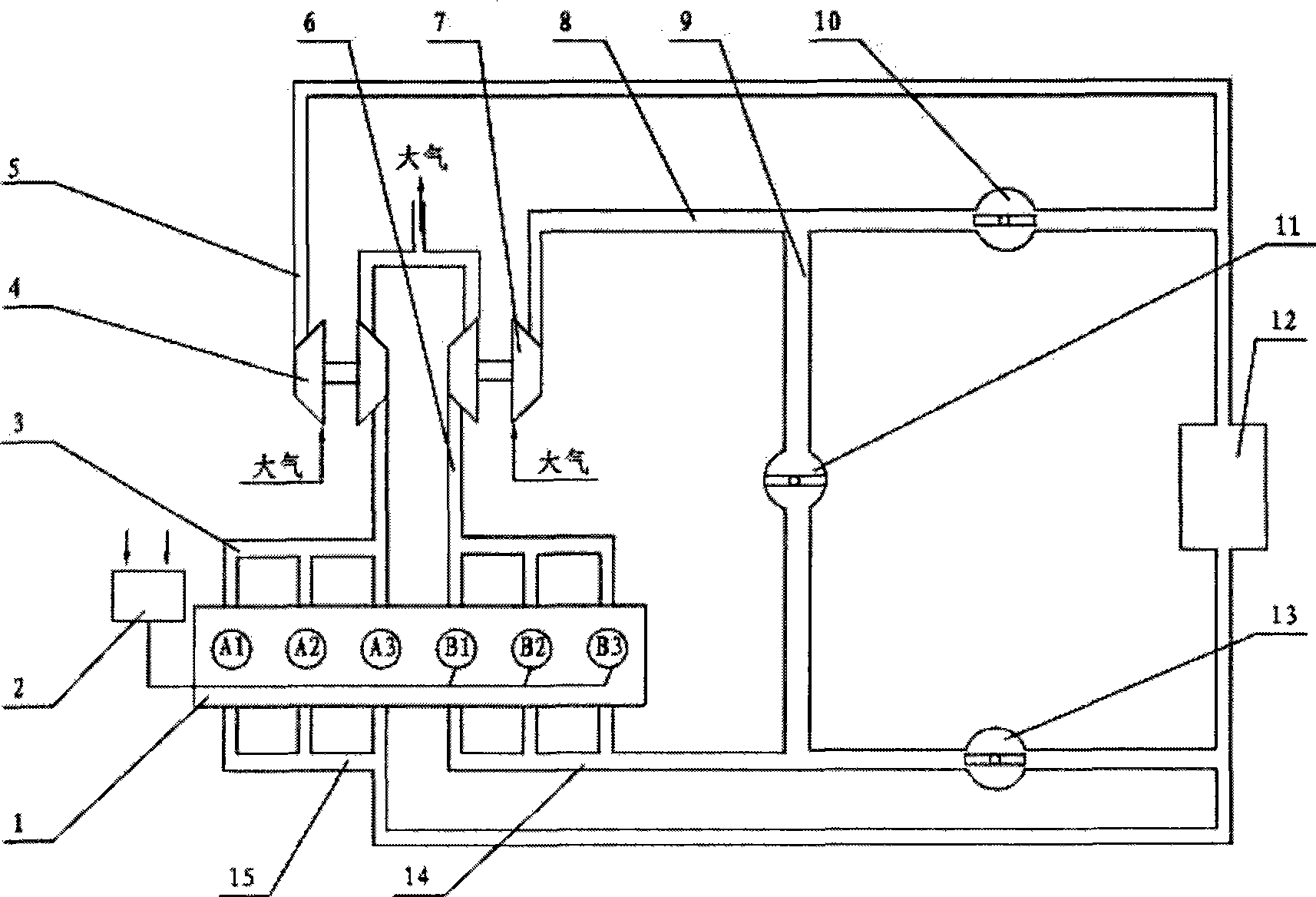

[0026] Such as figure 1 As shown, taking an in-line six-cylinder diesel engine as an example, this embodiment involves a diesel engine deactivation fuel-saving system with double superchargers and cylinder pressure relief devices, including a diesel engine 1, a set of cylinder pressure relief devices 2, a first Supercharging system, second supercharging system, intercooler 12. Diesel engine 1 is divided into A group of cylinders (including A1, A2, A3 cylinders) and B group of cylinders (including B1, B2, B3 cylinders) according to the requirements of the firing sequence, and the independent first supercharging system and the second supercharging system are used respectively. Connected to form two sets of booster systems and working cylinders that can operate independently. Cylinder pressure relief device 2 is respectively connected with the inlets of group B cylinders (including B1, B2 and B3 cylinders).

[0027] The first supercharging system includes a first exhaust manifo...

Embodiment 2

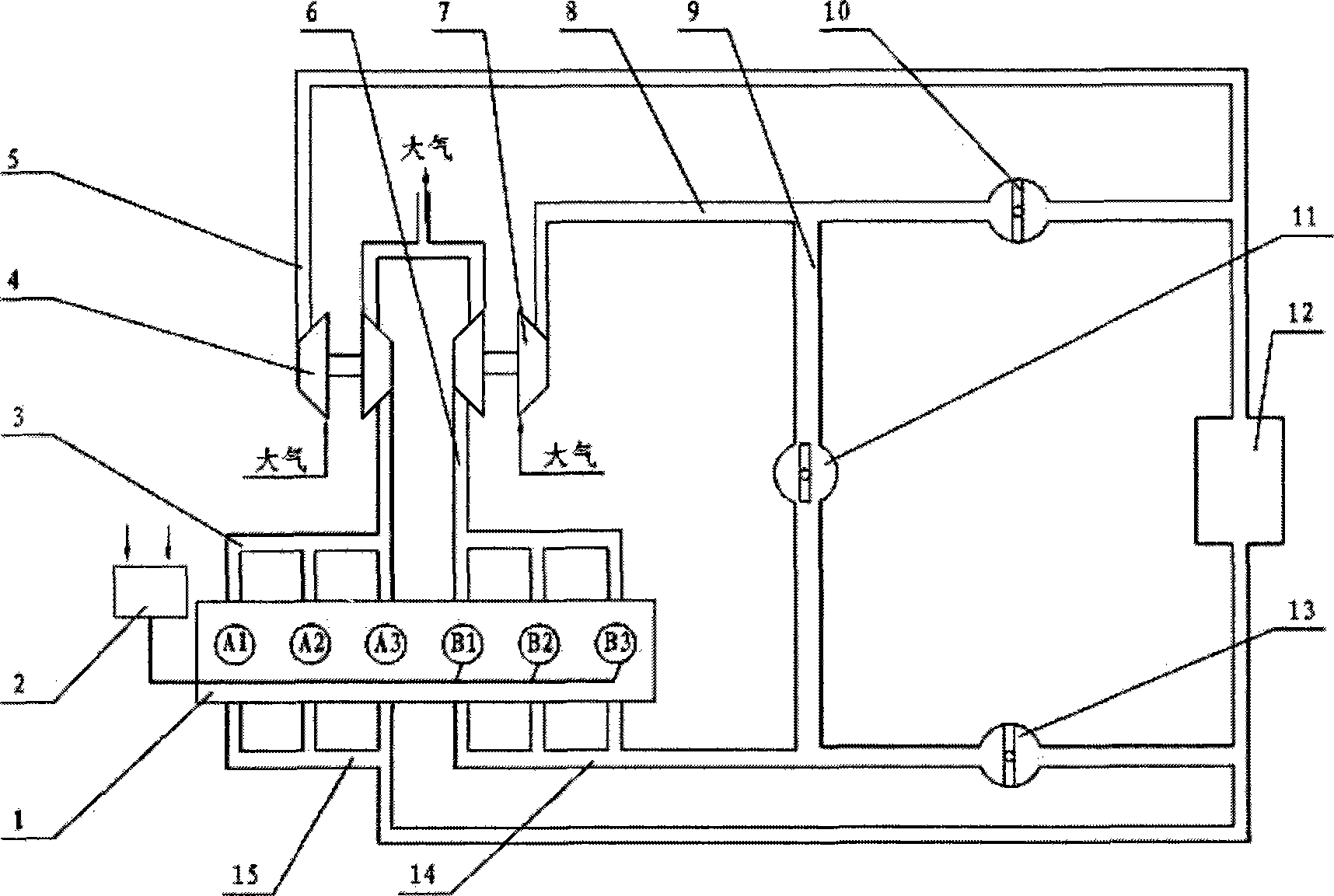

[0032] Such as image 3 As shown, it is the working condition of the fuel-saving system of the diesel engine with double supercharger and cylinder pressure relief device with three-way valve structure under high load conditions, including diesel engine 1, a set of cylinder pressure relief device 2, the first booster Compression system, second supercharging system, intercooler 12. Diesel engine 1 is divided into two groups of cylinders according to the requirements of the firing sequence, which are respectively connected with independent first supercharging system and second supercharging system to form two groups of supercharging systems and working cylinders that can operate independently. Cylinder pressure relief device 2 is respectively connected with B group cylinder inlet.

[0033] The structure of the first pressurization system is the same as that of Embodiment 1.

[0034] In this embodiment, the valve adopts a three-way valve, and the three-way valve is used to contr...

Embodiment 3

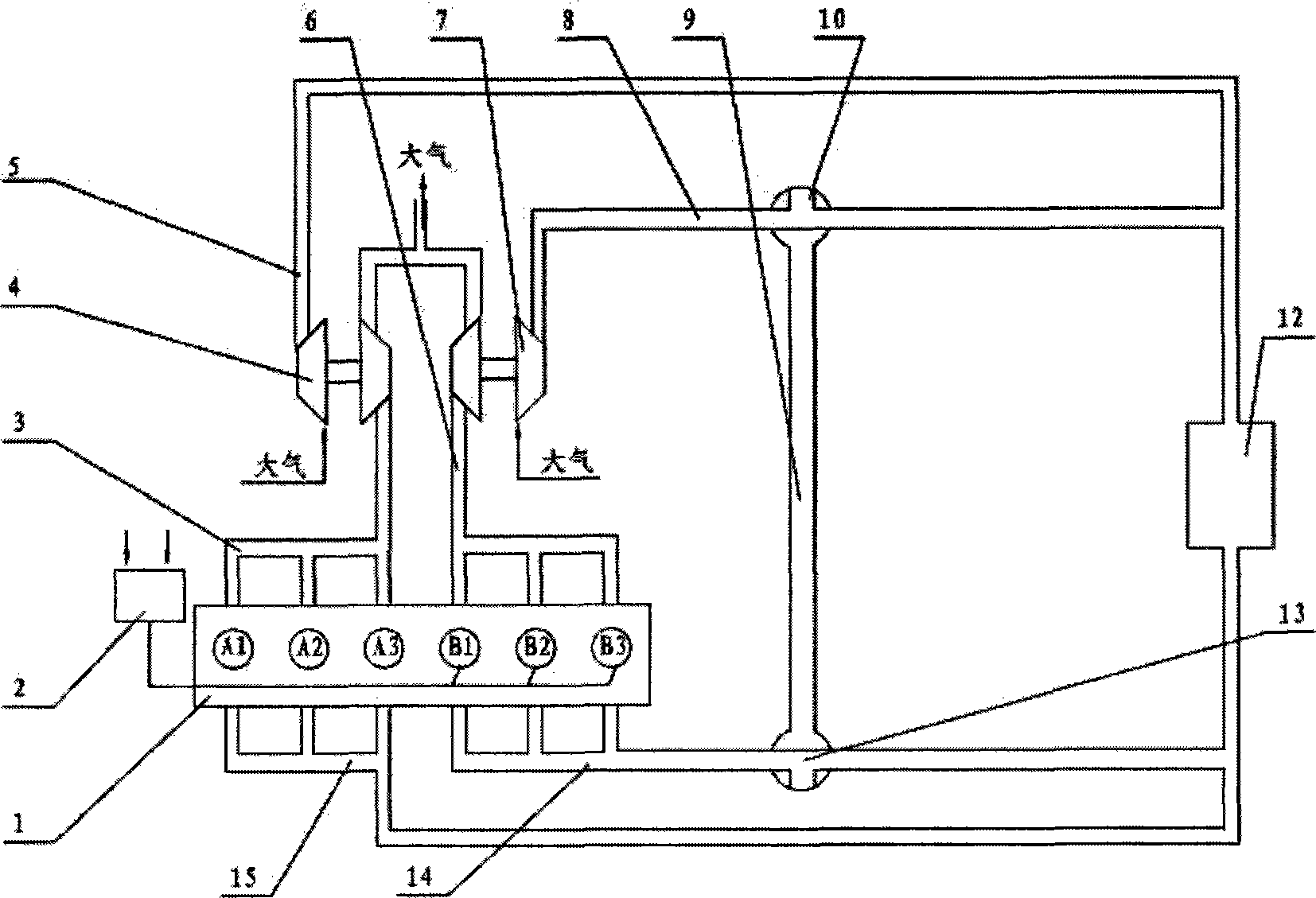

[0038] Figure 5 It is a V-type 12-cylinder diesel engine (taking the constant-pressure supercharging system as an example) under high-load conditions that adopts a butterfly valve structure with double superchargers and cylinder pressure relief devices. The working conditions of the diesel engine deactivation fuel-saving system. It includes a diesel engine 1, a set of cylinder pressure relief device 2, a first supercharging system, a second supercharging system, and an intercooler 12. Diesel engine 1 is divided into two groups of cylinders according to the firing order, wherein group A cylinders include cylinders A1, A2, A3, A4, A5, and A6, and group B cylinders include cylinders B1, B2, B3, B4, B5, and B6. The first supercharging system and the second supercharging system are connected to form two groups of independently operating supercharging systems and working cylinders. Cylinder pressure relief device 2 is respectively connected with B group cylinder inlet. The booste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com