Tire for vehicle wheels comprising crosslinked elastomeric composition

一种弹性组合物、弹性聚合物的技术,应用在车轮、特殊轮胎、轮胎零部件等方向,能够解决胎面硬度、拉伸强度和伸长率添加影响等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

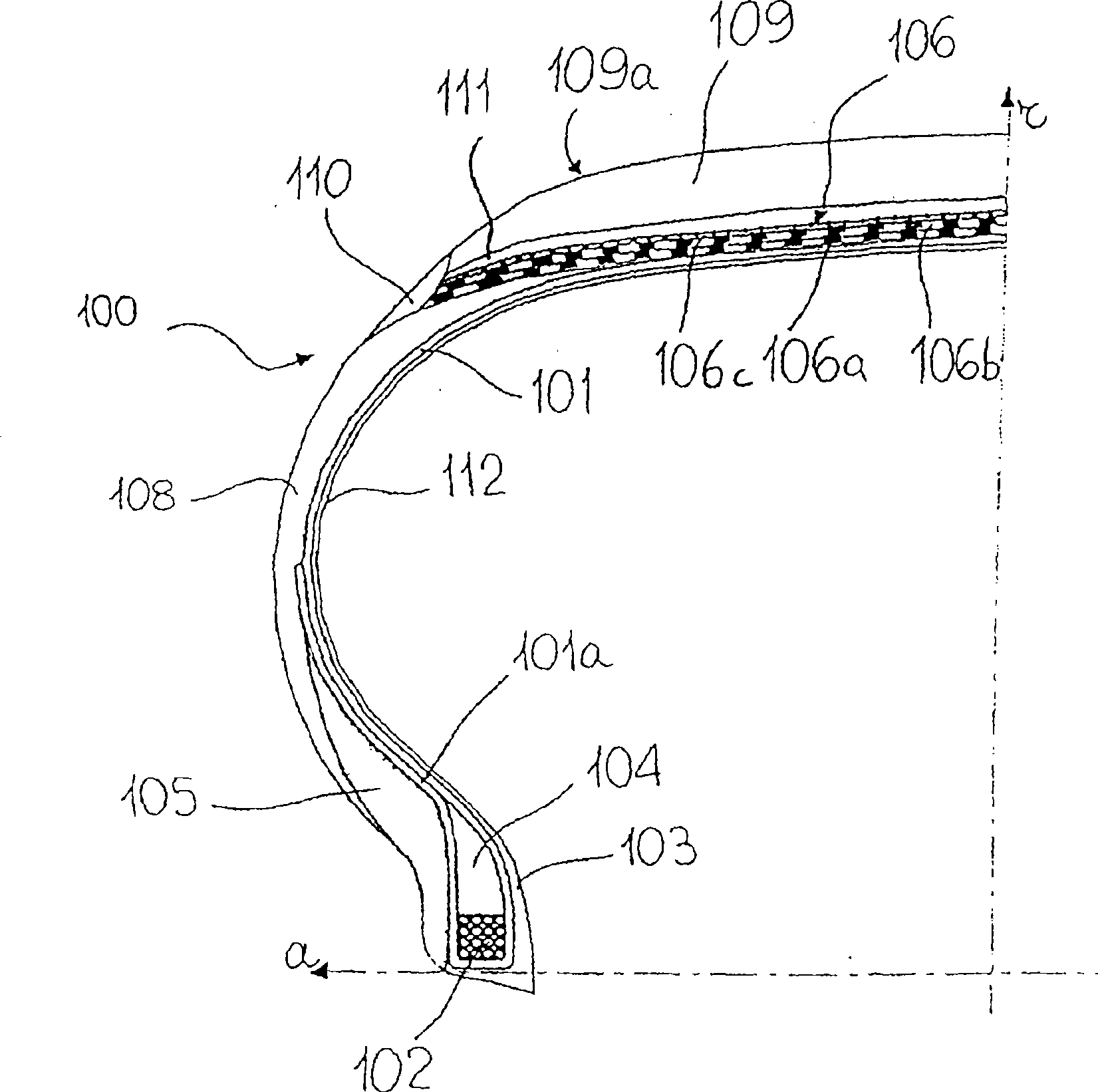

Image

Examples

Embodiment 1

[0111] Surface treatment of vulcanized rubber in subdivided form

[0112] Dispose of mechanically ground waste rubber according to the following procedure. Table 1 discloses the amounts (parts by weight) of the various components relative to 100 parts by weight of the ground waste rubber itself.

[0113] Table 1

[0114] Example 1 vulcanized rubber 100 oxidizing agent 12.65 Surfactant 1.98 water 12.65

[0115] Vulcanized rubber: mechanically ground waste rubber from scrap tires (<0.425 mm (40 mesh) - from Somir);

[0116] Oxidizing agent: Oxyper TM S131, sodium percarbonate obtained from Solvay;

[0117] Surfactant: Polyol from Perstorp Polyols TM PP50.

[0118] The mechanically ground waste rubber was added to a laboratory impeller mixer (BF srl Engineering) and maintained under stirring. Once the temperature reached 80 °C, the oxidizing agent and surfactant were added and the obtained mixture was stirred for 10 min. Then, th...

Embodiment 2

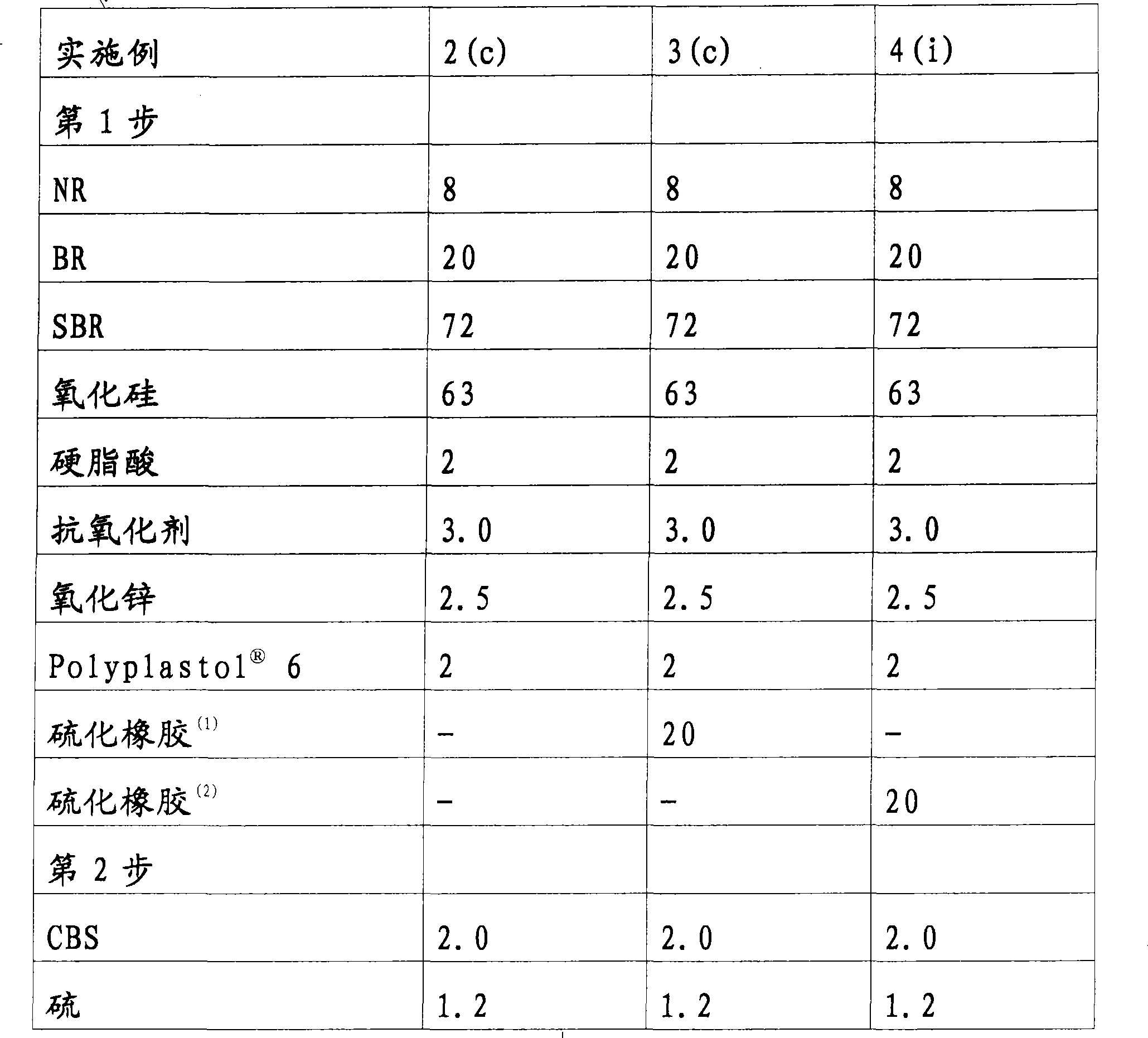

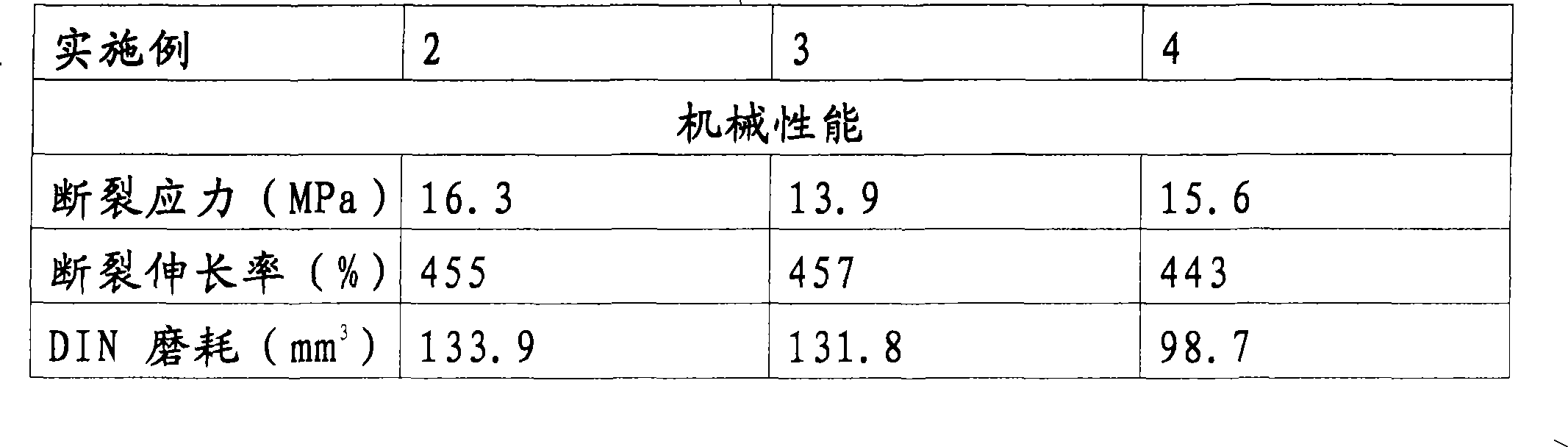

[0120] Preparation of crosslinkable elastomeric compositions

[0121] The crosslinkable elastomeric compositions given in Table 2 were prepared as follows (amounts of the various components given in phr).

[0122] All components except sulfur and accelerator were mixed together in an internal mixer (model Pomini PL 1.6) for about 5 minutes (first step). Once the temperature reached 145±5°C, the elastomeric composition was discharged. Sulfur and accelerators are then added and mixed in the mill (second stage).

[0123] Table 2

[0124]

[0125] (c) Comparison (i) Invention

[0126] NR: natural rubber;

[0127] BR: cis-1,4-polybutadiene ( BR 40-EniChemElastomeri);

[0128] SBR: Styrene-butadiene rubber (Buna VLS 5025-1 HM-Bayer AG)

[0129] Silica: Precipitated silica ( 1165 MP-Rhone-Poulenc);

[0130] 6: Mixture of zinc salts of fatty acids (palmitic acid, stearic acid and oleic acid present in major amounts) (Great Lakes Chemical Corp.);

[0131] vulcaniz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com