Safe infusion apparatus and preparation method thereof

A safe and infusion device technology, applied in the field of medical devices, can solve the problems of infusion device damage, pipeline entanglement, leakage, etc., and achieve the effects of excellent mechanical properties, good bonding performance, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

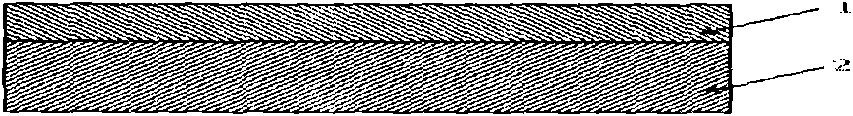

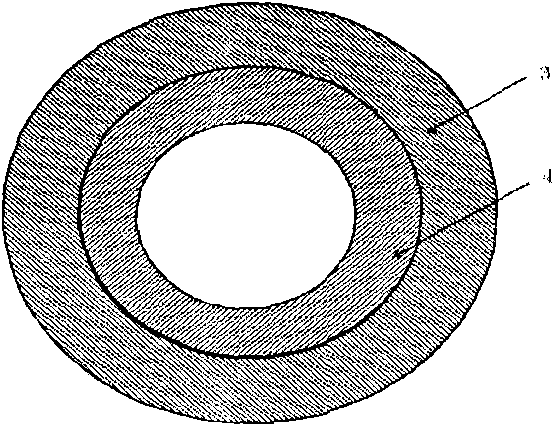

[0034] Weigh A1 and B1 materials and add them to the double-layer co-extrusion blow molding unit respectively. The screw diameter of the extruder unit is 40mm, the length-to-diameter ratio is 36, and the head is the center feed of the inner layer and the side feed of the outer layer for co-extrusion. Blow-molded structure. Set the temperature of the feed section of the extruder for material A1 to 150-160°C, the temperature of the compression section to 160-170°C, and the temperature of the metering section to 170-180°C; set the temperature of the feed section of the extruder for material B1 to 140-155°C, The temperature of the compression section is 150-165°C, the temperature of the metering section is 160-175°C; the temperature of the co-extrusion blow molding head is set at 170-180°C.

[0035] After the polyurethane and polyvinyl chloride are dried, add them into the hopper of the polyurethane extruder and the hopper of the polyvinyl chloride extruder of the double-layer co-...

Embodiment 2

[0039] Weigh the materials A1 and B2 and add them to the double-layer co-extrusion blow molding unit. The screw diameter of the extrusion unit is 40 mm, and the aspect ratio is 36. Set the temperature of the feeding section of the extruder for A1 material to 150-160 °C, the temperature of the compression section to 160-170 °C, and the temperature of the metering section to 170-180 °C; set the temperature of the feeding section of the extruder for material B2 to 140-155 °C, The temperature of the compression section is 150-165 °C, the temperature of the metering section is 160-175 °C; the temperature of the co-extrusion blow molding head is set to 170-180 °C. After drying the polyurethane and polyvinyl chloride, the weight ratio of 1:3 was added into the polyurethane extruder hopper and the polyvinyl chloride extruder hopper of the double-layer co-extrusion blow molding unit, respectively. The feed rate ratio of the extruder was 1:2.4, and the blow-molded polyurethane / polyvinyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com