Environment-friendly and low-cost method for eluting pollutants on absorbent surface

A technology of pollutants and adsorbents, which is applied in the field of eluting heavy metal pollutants on the surface of metal oxide adsorbents, and can solve problems such as complex technical conditions, increased costs, and secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The preparation of the adsorbent of embodiment 1 load heavy metal pollutants

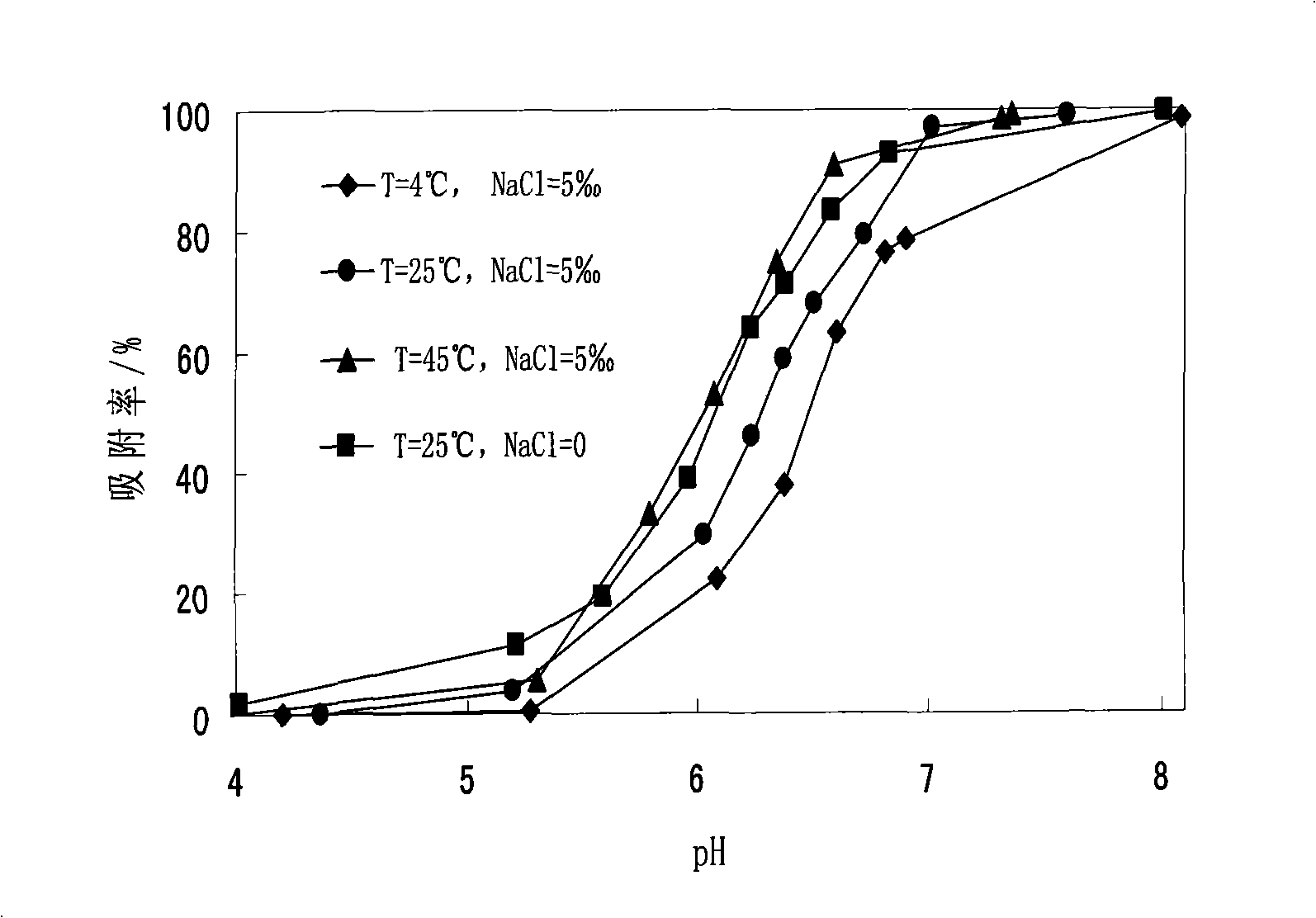

[0017] Weigh 0.03g anatase TiO 2 , dissolved in 28.5ml of ultrapure water, stirred at 25°C for 2h, then added 1.5ml to a concentration of 1g·L -1 Zn solution, adjust the pH value of the adsorption system to keep it near 6.4, and balance for 12h. Centrifuge the above fully reacted mixed solution, pour off the supernatant, and the obtained solid part is the adsorbent required for the elution test.

Embodiment 2

[0018] The elution effect under the different ionic strengths of embodiment 2

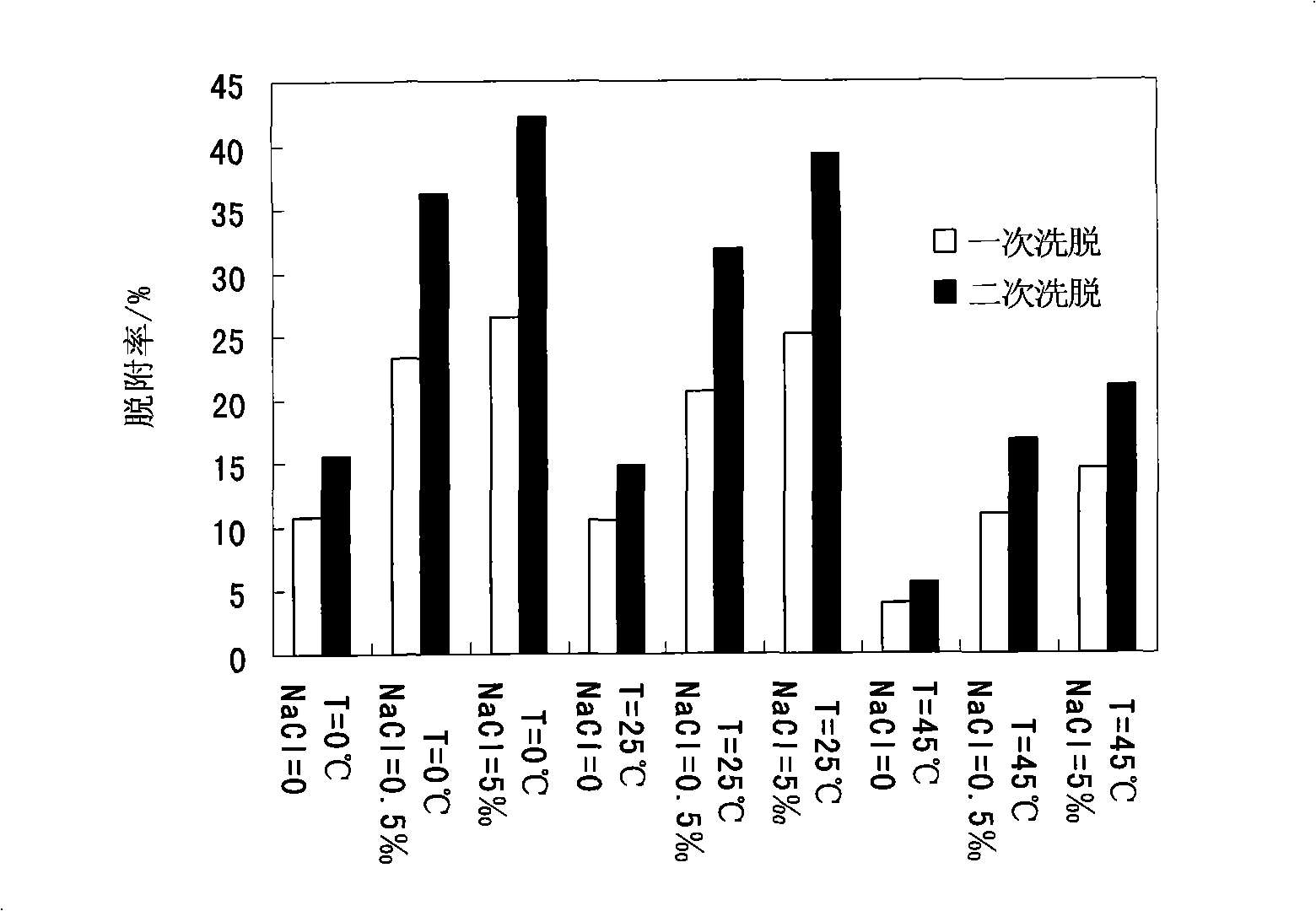

[0019] With 30ml, the sodium chloride solution that mass fraction is respectively 0, 0.5‰, 5‰, is poured into the adsorbent solid surface that has loaded heavy metal Zn prepared in the example 1, makes it fully mix, under 25 ℃ of conditions, Shake for 2 hours, then centrifuge for 10 minutes, take the supernatant to pass through a 0.22 micron filter membrane, measure the Zn content in the supernatant, and calculate the elution efficiency. The experiment was repeated to obtain the efficiency of the secondary elution. The result is as figure 2 shown. Depend on figure 2 It can be seen that with the increase of the mass fraction of sodium chloride, the elution rate gradually increased from 15% to 40%.

Embodiment 3

[0020] The elution effect under the different temperature conditions of embodiment 3

[0021] According to the same operating conditions as in Example 2, the temperatures were respectively controlled at 4°C, 25°C, and 45°C, and the elution efficiencies were measured respectively. from figure 2 It can be seen that the elution efficiency is significantly higher at low temperature than at high temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com