Method of fast-flotation of bauxite with low Al/Si (aluminum/silicon) ratio

A technology of aluminum-silicon ratio and bauxite, which is applied in the cleaning methods of tools, flotation, chemical instruments and methods, etc., can solve the problems of large return volume of medium ore, small circulation volume, entrainment of ore sludge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

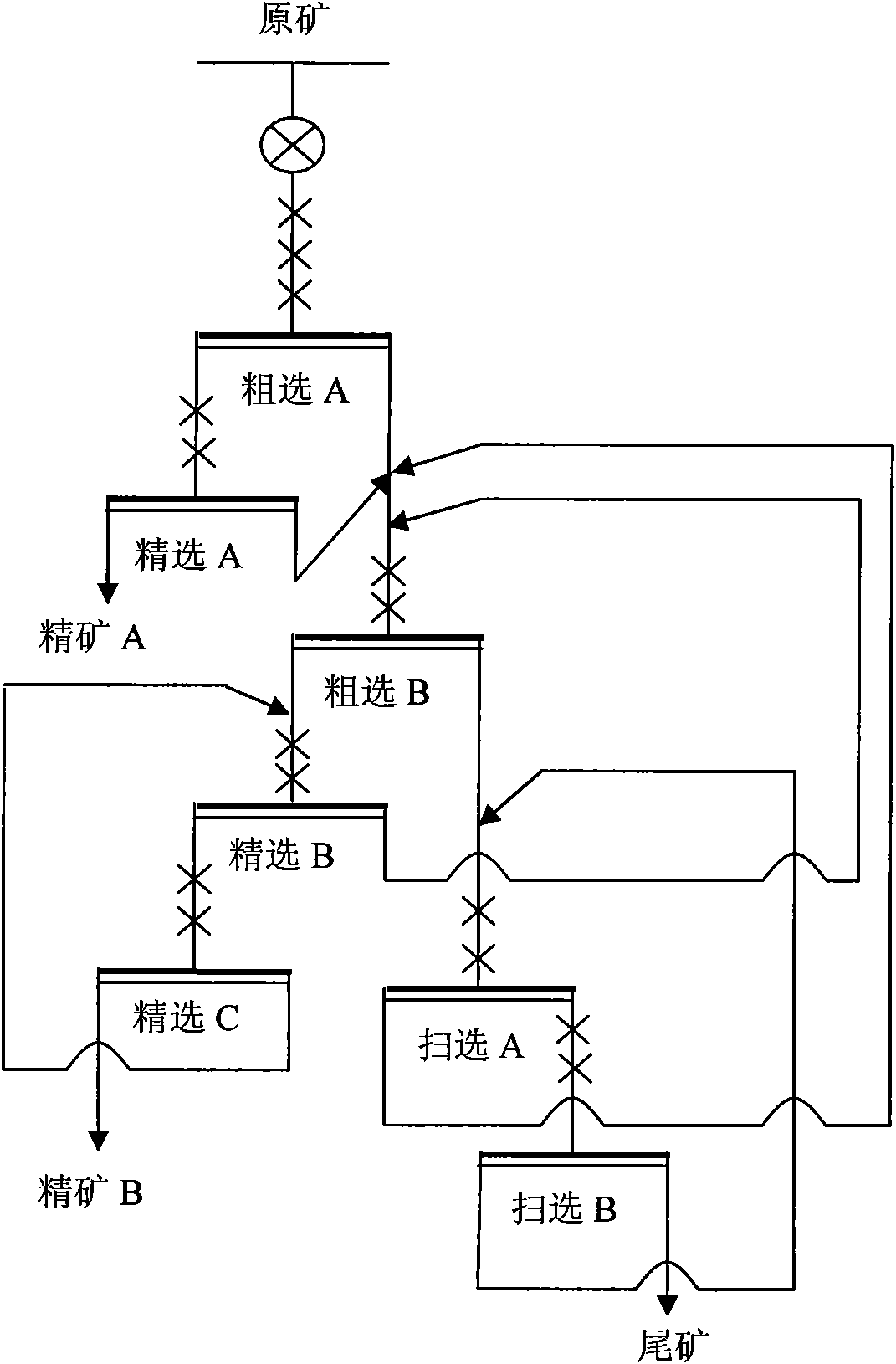

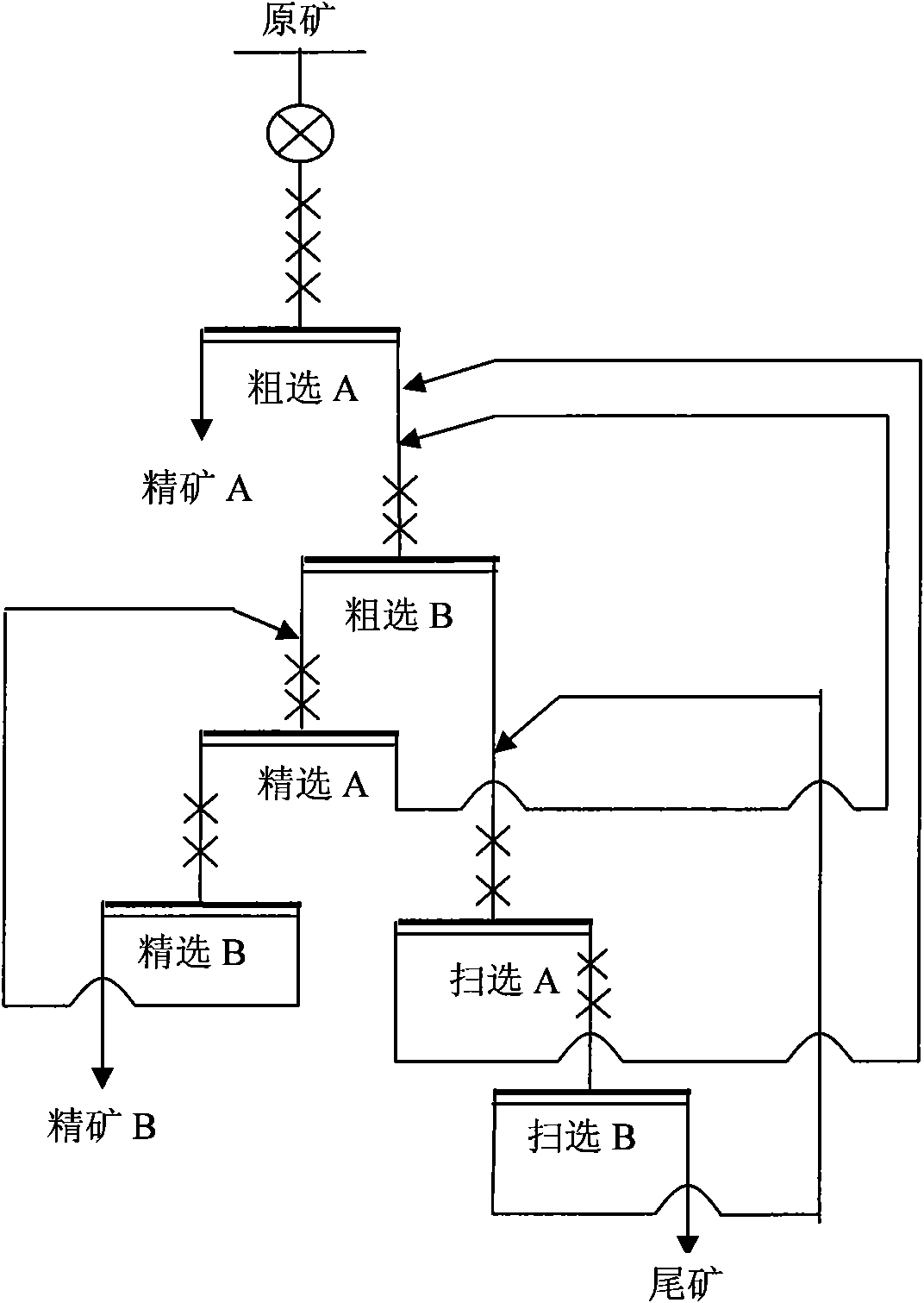

Image

Examples

Embodiment 1

[0021] This method was used to conduct a flotation test on a bauxite mine in Henan. Al in this mineral 2 o 3 The content is 63.97, SiO 2 The content is 11.20, and the aluminum-silicon ratio is 5.71.

[0022] Grind the low-aluminum-silicon ratio bauxite to -0.074mm, accounting for 90%, add 2500 g / t of sodium carbonate during the grinding process; add sodium carbonate to adjust the slurry to pH9.5, add inhibitor water glass 150g / t , collector oleic acid 800g / t, the first part of the concentrate with aluminum-silicon ratio above 8.5 is separated after roughing and a beneficiation; inhibitor sodium silicate 150g / t is added to the tailings, collector oleic acid 800g / t, the second part of concentrate is separated by roughing and two beneficiation.

[0023] After adopting the method, a bauxite concentrate with a total recovery rate of 89.8% and an aluminum-silicon ratio of 9.56 can be obtained.

Embodiment 2

[0025] This method was used to carry out the flocculation and sedimentation test on a bauxite mine in Henan. Al in this mineral 2 o 3 The content is 56.24, SiO 2 The content is 11.53, and the aluminum-silicon ratio is 4.88.

[0026] Grind the low-alumina-silicon ratio bauxite to -0.074mm, accounting for 90%, add 2500 g / t of sodium carbonate during the grinding process; add sodium carbonate to adjust the slurry to pH 10, add inhibitor sodium hexametaphosphate 60g / t , the collector oleic acid is 900g / t, and the first part of the concentrate with an aluminum-silicon ratio above 8.5 is separated after rough separation; the inhibitor sodium hexametaphosphate 60g / t is added to the tailings, and the collector oleic acid is 900g / t , the second part of the concentrate is separated by roughing and two beneficiation.

[0027] After adopting the method, a bauxite concentrate with a total recovery rate of 89.05% and an aluminum-silicon ratio of 8.01 can be obtained.

Embodiment 3

[0029] Add 4500 g / t of sodium carbonate during the grinding process; add sodium carbonate to adjust the slurry to pH 10.5, add inhibitor sodium hexametaphosphate 80 g / t during the first flotation process; the remaining steps and conditions are the same as in Example 1.

[0030] After adopting the method, a bauxite concentrate with a recovery rate of 95.13% and an aluminum-silicon ratio of 8.08 can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com