Production equipment of non-woven fabric compound economic master batch

A technology for production equipment and non-woven fabrics, applied in the field of production equipment for non-woven composite economic masterbatches, can solve the problems of extremely high production process requirements, long material residence time, time-consuming and laborious, etc., to reduce material costs and save money. energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Preparation

[0026] Weigh 15kg of polypropylene resin with a melting index of 90, 8kg of polypropylene resin with a melting index of 3, 60kg of nano-scale activated calcium carbonate, 9kg of polyethylene wax, 0.6kg of composite antioxidant, 2kg of zinc stearate, titanate 2kg, white oil 1.7kg, rutile titanium dioxide 1.7kg.

[0027] 2. Ingredients

[0028] Put the above-mentioned raw materials in a stirring container according to the proportion, and stir and mix evenly.

[0029] 3. Forming

[0030] Send the well-mixed compound into the twin-screw extruder to make it fully mixed, melted, dispersed and extruded. During this process, the temperature is controlled by circulating water.

[0031] 4. Granulation

[0032] The molded product extruded by the twin-screw extruder is sent to the single-screw extruder, and the finished non-woven fabric is obtained through melt extrusion, pelletizing, and vibrating sieve screening, and can be packaged.

Embodiment 2

[0034] 1. Preparation

[0035] Weigh 15kg of polypropylene resin with a melting index of 60, 8kg of polypropylene resin with a melting index of 30, 60kg of nano-scale activated calcium carbonate, 9kg of polyethylene wax, 0.6kg of composite antioxidant, 2kg of zinc stearate, titanate Coupling agent 2kg, white oil 1.7kg, rutile titanium dioxide 1.7kg.

[0036] The rest are the same as Example 1.

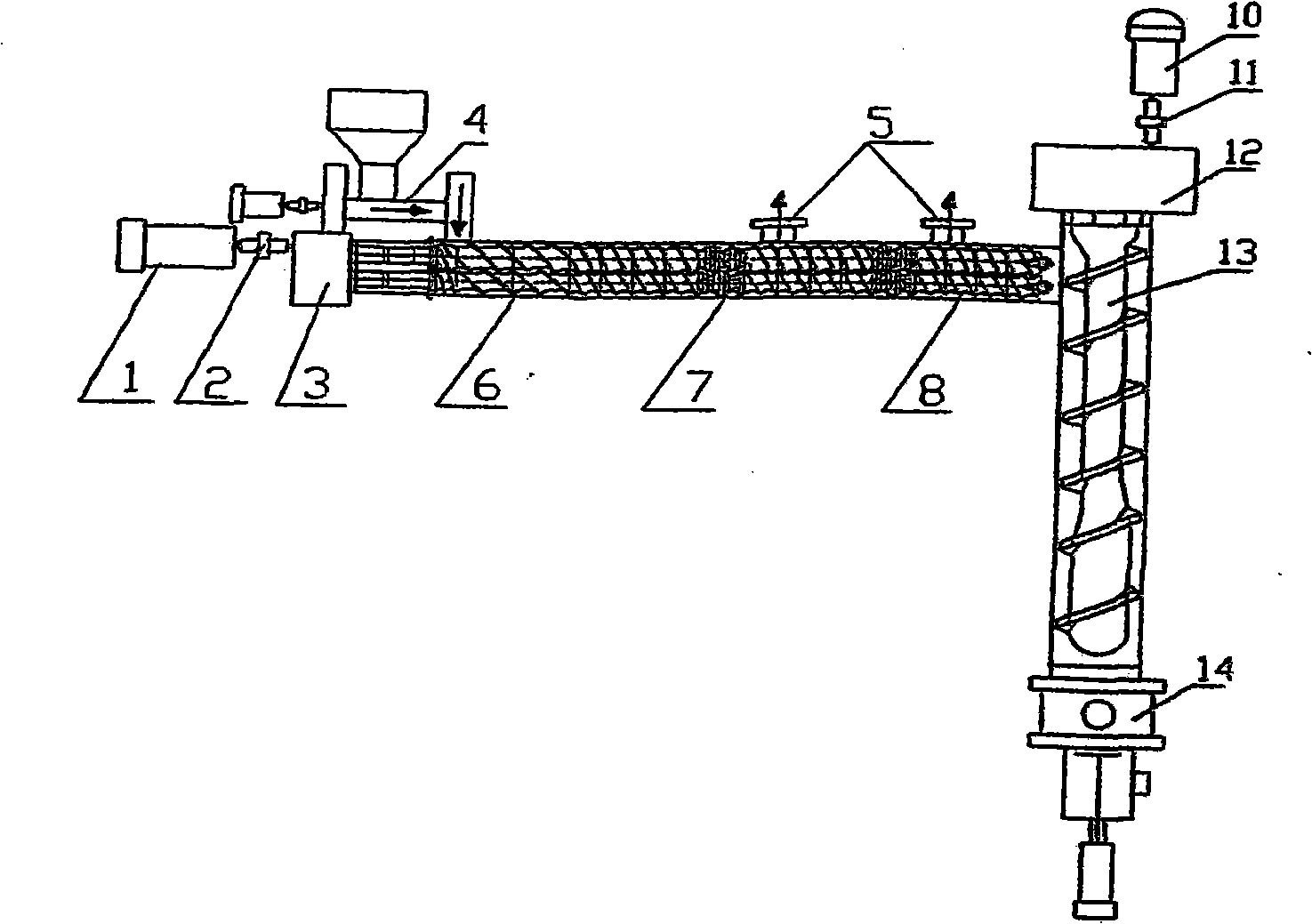

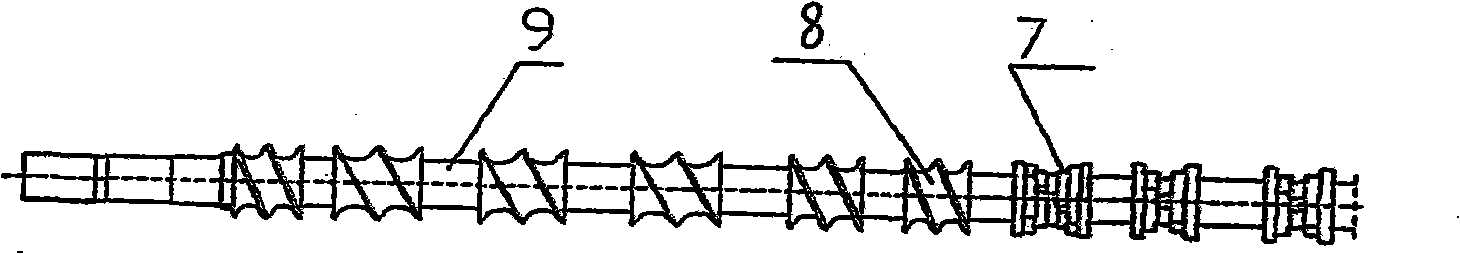

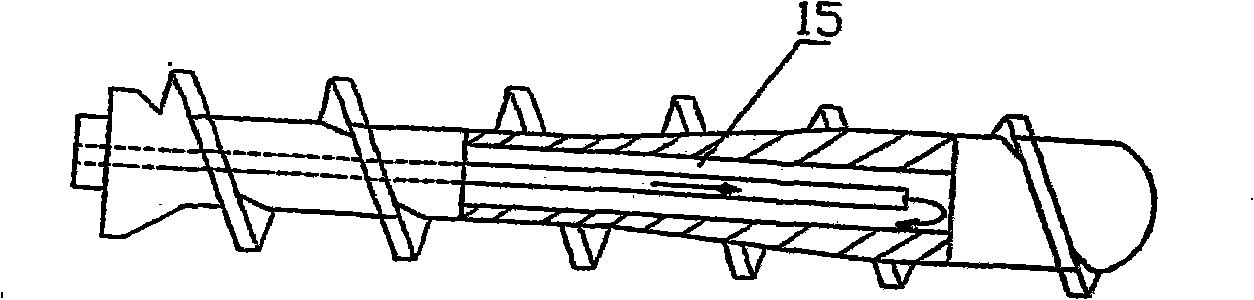

[0037] The above production process uses a stepped screw extruder, its structure is as follows figure 1 shown. The stepped screw extruder consists of a first-stage twin-screw extruder and a second-stage single-screw extruder. The first-stage twin-screw extruder and the second-stage single-screw extruder are arranged in a "T" shape, and the outlet of the first-stage twin-screw extruder is connected to the inlet of the second-stage single-screw extruder. The material ends are connected.

[0038] The first-stage twin-screw extruder is mainly composed of a driving motor I1, a coupling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com