Method for removing heavy metallic salts from industrial waste water by using egg shells

A technology for industrial wastewater and heavy metal salts, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve problems such as poor impact resistance to running water and easy loss, unresolved metal recovery methods, difficult desorption of adsorbed metals, etc. , to achieve the effect of low cost, good natural settlement and excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

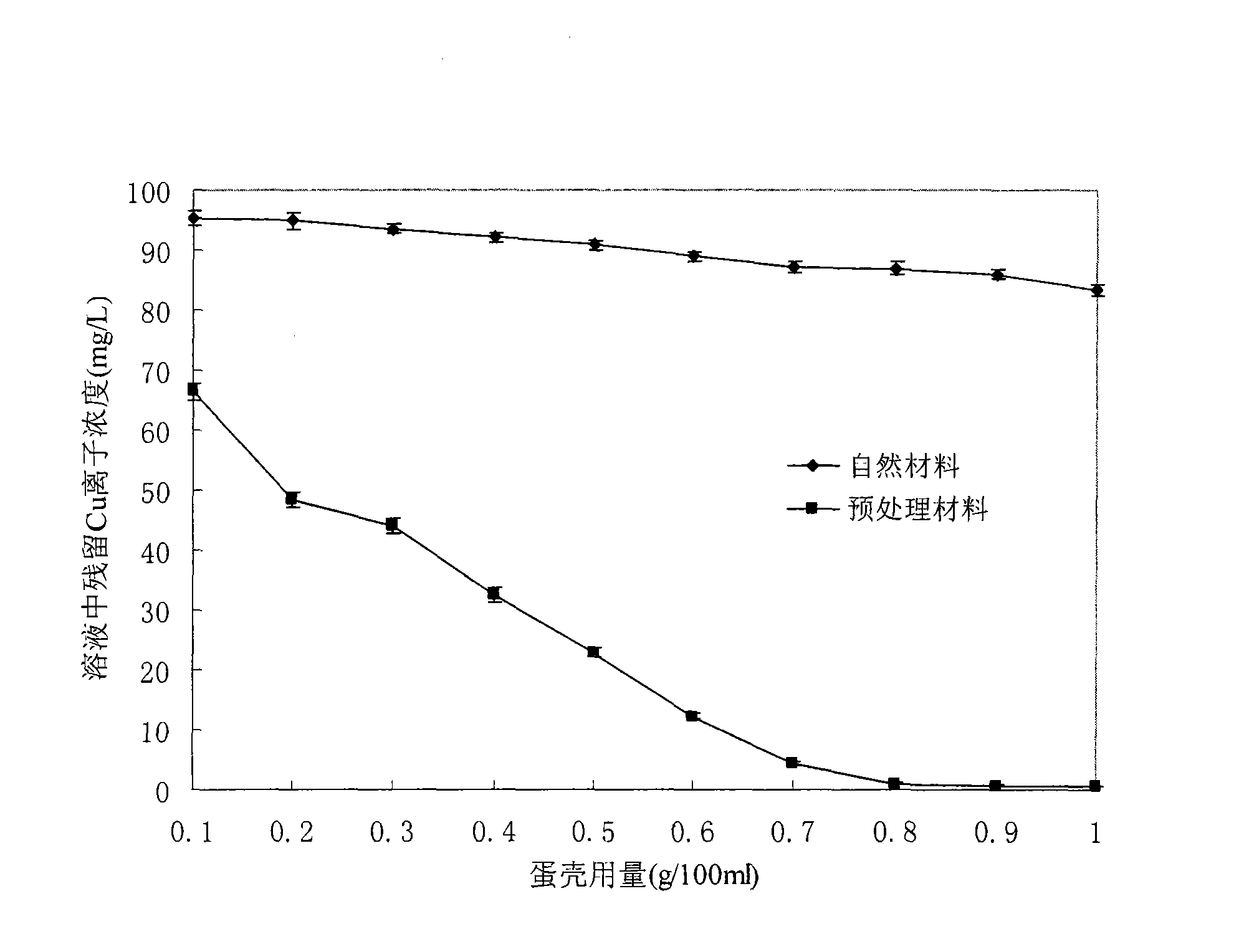

[0023] Embodiment 1. eggshell preparation consumption is to Cu 2+ Remove the effect of the effect

[0024] 100mL of heavy metal salt solution (initial Cu 2+ Concentration is 100mg / L, solution initial pH 5) is placed in the Erlenmeyer flask of 250mL, adds a certain amount of eggshell preparation (referring to figure 1 ), 32°C, 200rpm shaker adsorption for 2 hours. Pour the adsorbed solution into a centrifuge tube, centrifuge at 4800rpm for 5 minutes, and take the supernatant. The standard method of Perkin-Elmer Company is used for determination by atomic absorption instrument.

[0025] The reference standard is "National Standard Sewage Comprehensive Discharge Standard of the People's Republic of China" (GB8978-1996). The discharge standards for total cadmium, total copper and total zinc are shown in Table 1 below.

[0026] Table 1 Total Cadmium, Total Copper and Total Zinc Discharge Standards (GB8978-1996) (Note: There is no total Fe discharge standard in this standard) ...

Embodiment 2

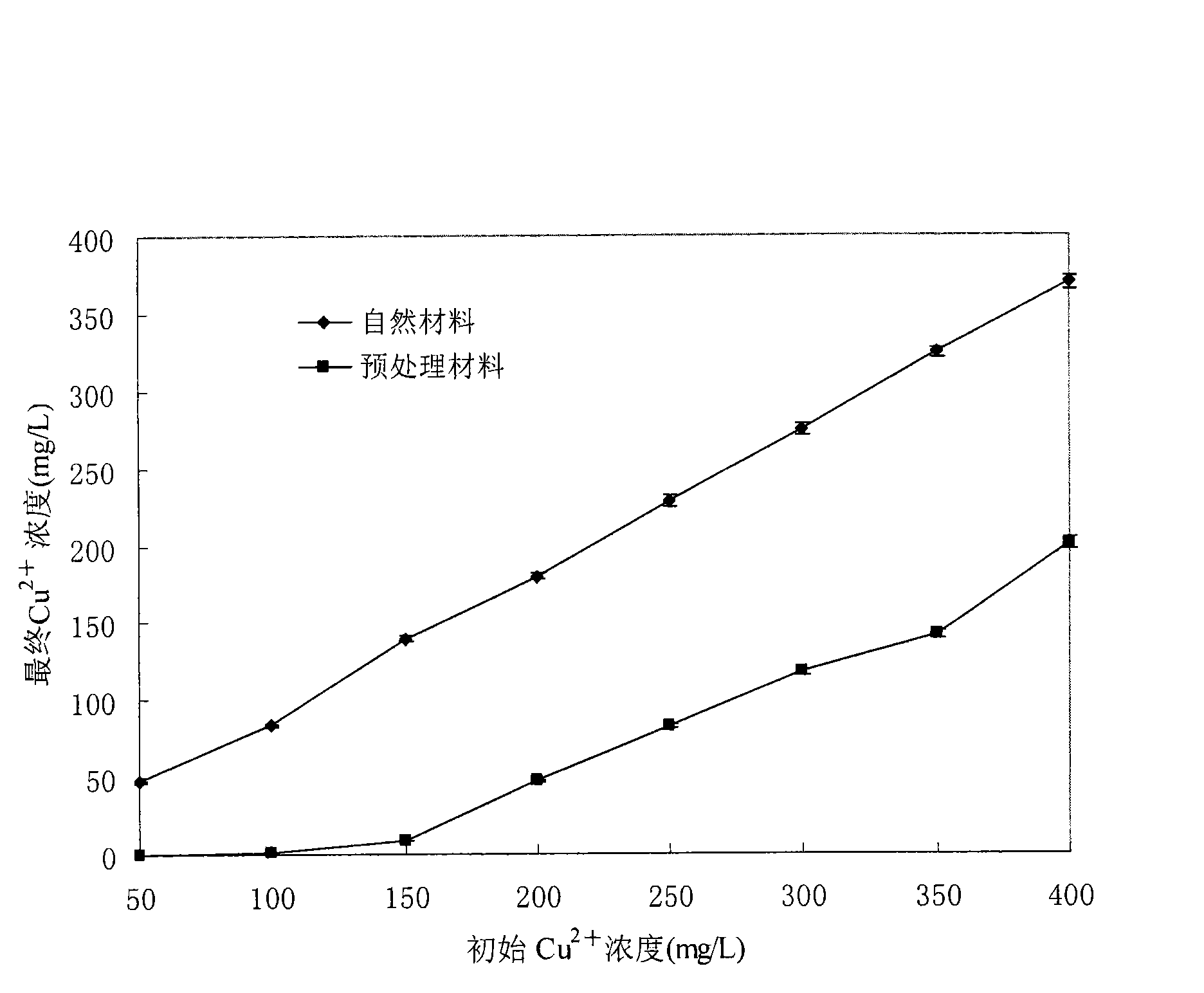

[0029] Embodiment 2. heavy metal salt solution initial Cu 2+ Concentration vs. Cu 2+ Remove the effect of the effect

[0030] 100mL of heavy metal salt solution (its initial Cu 2+ Concentration see figure 2 , the initial pH of the solution was 5) placed in a 250mL Erlenmeyer flask, added 1g / 100ml eggshell preparation, and adsorbed on a shaker at 200rpm at 32°C for 2 hours. Pour the adsorbed solution into a centrifuge tube, centrifuge at 4800rpm for 5 minutes, and take the supernatant. The standard method of Perkin-Elmer Company is used for determination by atomic absorption instrument. The reference standard is the same as Table 1.

[0031] It was found that with the initial Cu 2+ As the concentration increased, the removal efficiency decreased significantly. The removal of natural eggshell materials does not meet the national emission standards for copper. Only the pretreated eggshell material in the initial Cu 2+ When the concentration is 100mg / L, the removal effec...

Embodiment 3

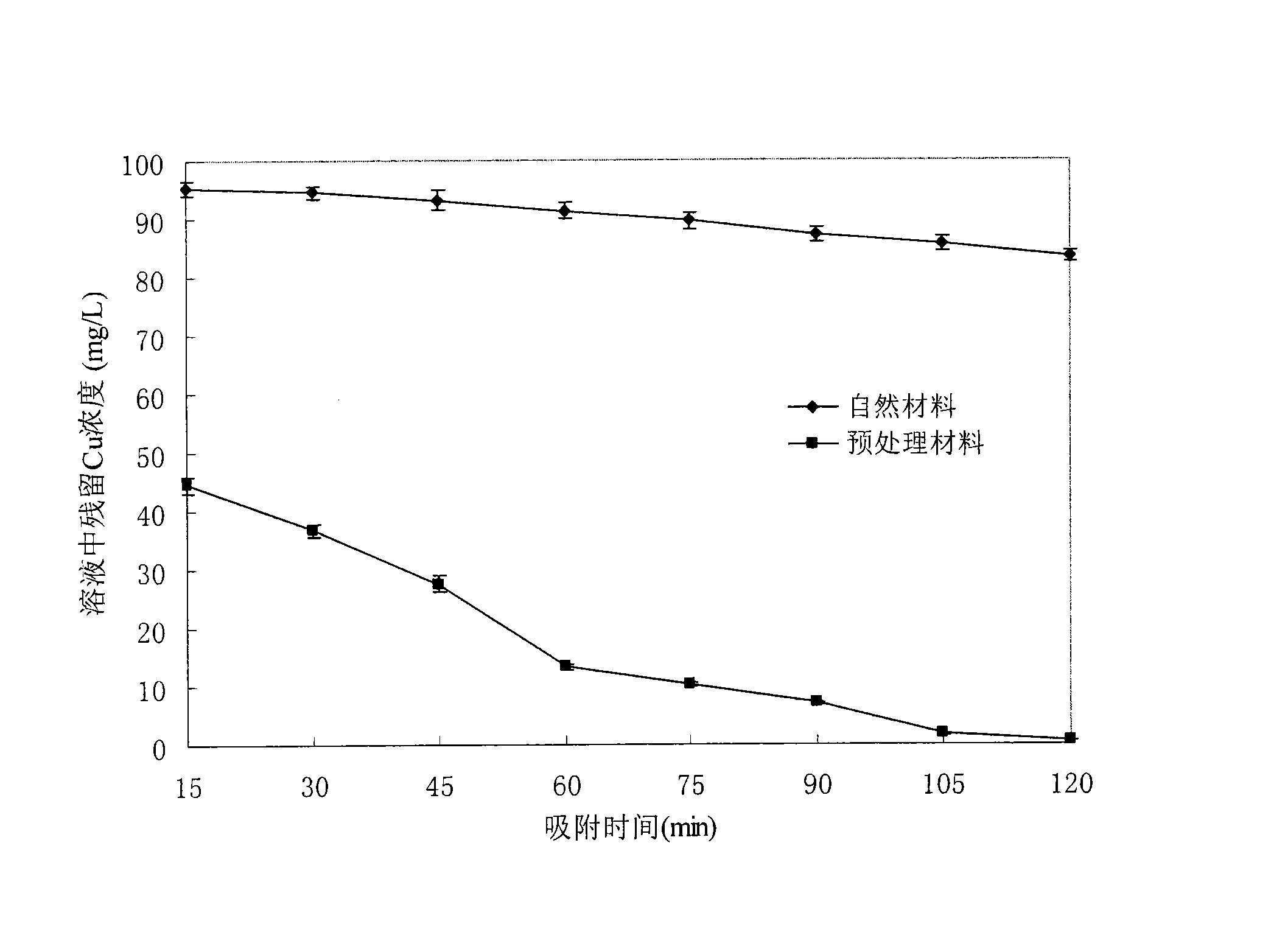

[0032] Example 3. Adsorption time on Cu 2+ Remove the effect of the effect

[0033] 100mL of heavy metal salt solution (initial Cu 2+ The concentration is 100mg / L, the initial pH of the solution is 5) placed in a 250mL Erlenmeyer flask, add 1g / 100ml eggshell preparation, 32°C, 200rpm shaker adsorption for a period of time (see image 3 ). Pour the adsorbed solution into a centrifuge tube, centrifuge at 4800rpm for 5 minutes, and take the supernatant. The standard method of Perkin-Elmer Company is used for determination by atomic absorption instrument. The reference standard is the same as Table 1.

[0034] It was found that natural eggshell materials had little removal effect even with prolonged adsorption time. The pretreatment eggshell material is adsorbed for 105 minutes, and the removal effect reaches the national third-level emission standard for copper, and the adsorption is 120 minutes, and the removal effect reaches the national second-level emission standard for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com