Ferroelectric glass-ceramic dielectric material and preparation method thereof

A technology of dielectric material and glass-ceramic, which is applied in the direction of fixed capacitor dielectric and components of fixed capacitor, etc., to achieve the effect of high breakdown field strength and high dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

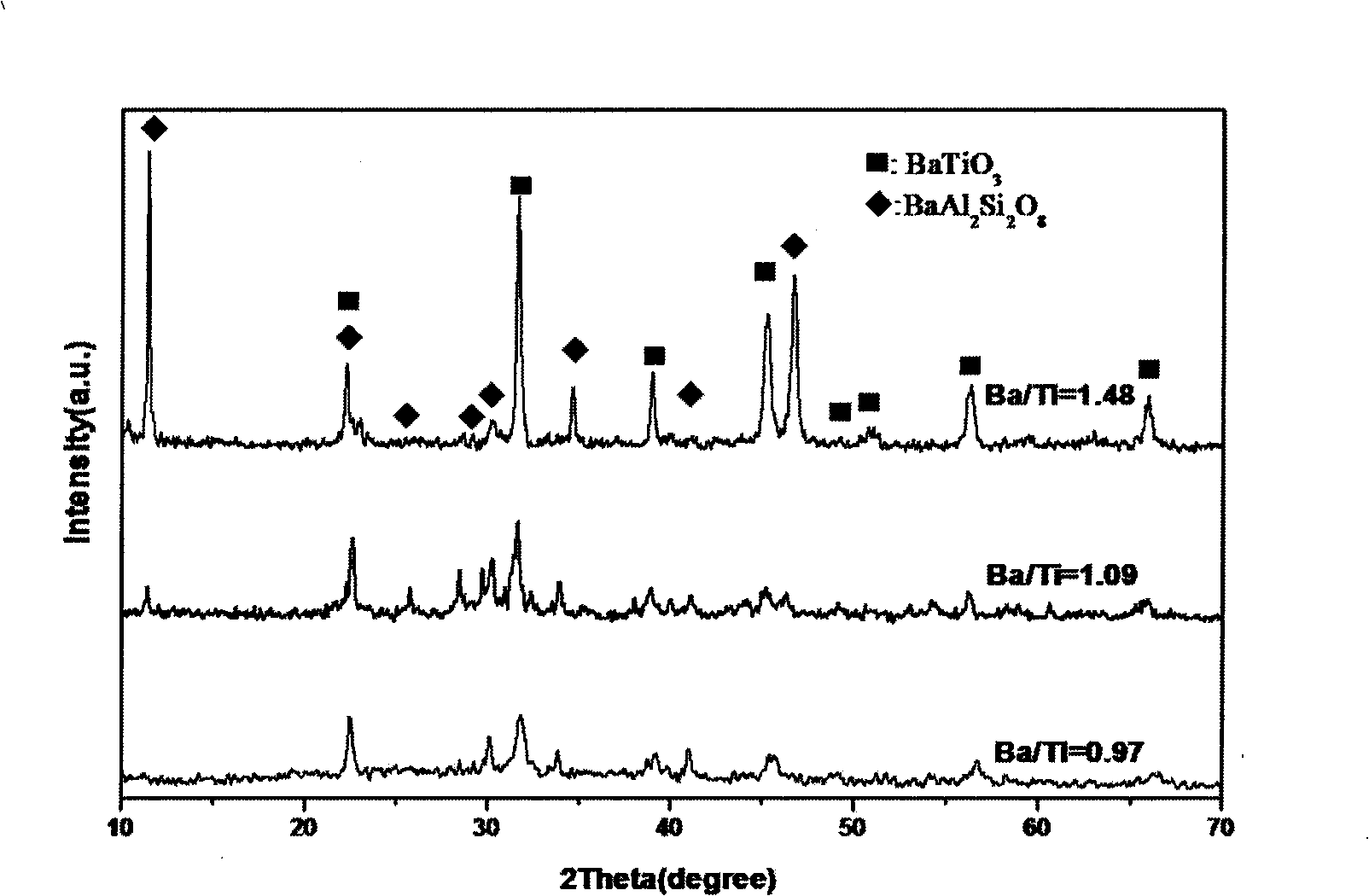

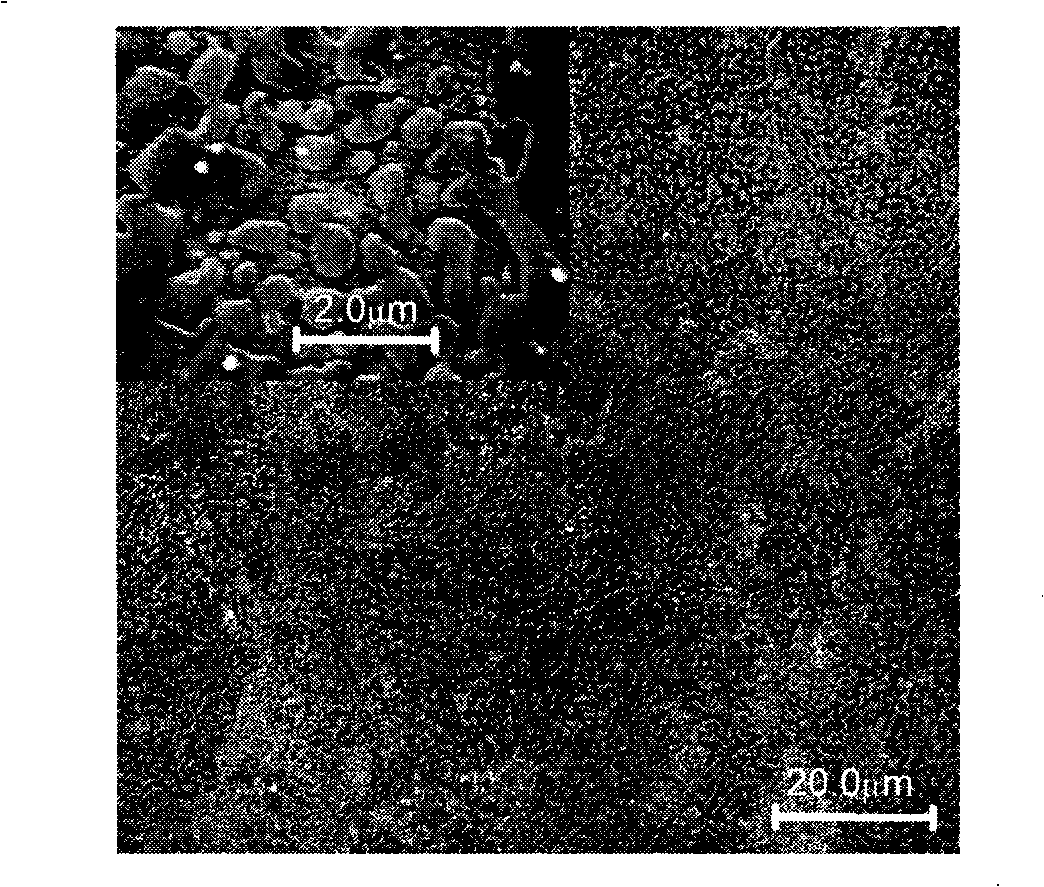

[0026] A ferroelectric glass-ceramic dielectric and its preparation method, the composition of which is Ba / Ti=0.97.

[0027] BaCO with a purity greater than 99% 3 、TiO 2 , SiO 2 , and Al 2 o 3 As the starting material, according to BaO:TiO 2 : SiO 2 :Al 2 o 3 =a: b: c: d (wherein a=0.33, b=0.34, c=0.22, d=0.11, a+b+c+d=1) molar ratio batching, the total consumption of all raw materials is 100 grams, Ba / Ti = 0.97. Then these raw materials are added into a planetary ball mill with ball milling media (zirconia balls and absolute ethanol, wherein absolute ethanol is the ball milling media) to grind for 4-6 hours, and after drying, they are melted at 1400-1650°C for 2-6 hours;

[0028] The high-temperature melt obtained in step 1 is subjected to a double-roll cold rolling process to prepare a continuously adjustable glass sheet with a thickness between 0.5 and 1 mm;

[0029] The glass flakes prepared in step 2 are subjected to controlled crystallization. The crystallizat...

Embodiment 2

[0032] A ferroelectric glass-ceramic dielectric and a preparation method thereof, the composition of which is Ba / Ti=1.09.

[0033] BaCO with a purity greater than 99% 3 、TiO 2 , SiO 2 , and Al 2 o 3As the starting material, according to BaO:TiO 2 : SiO 2 :Al 2 o 3 =a: b: c: d (wherein a=0.35, b=0.32, c=0.22, d=0.11, a+b+c+d=1) molar ratio batching, the total consumption of all raw materials is 100 grams, Ba / Ti=1.09. Then these raw materials are added into a planetary ball mill with ball milling media (zirconia balls and absolute ethanol, wherein absolute ethanol is the ball milling media) to grind for 4-6 hours, and after drying, they are melted at 1400-1650°C for 2-6 hours;

[0034] The high-temperature melt obtained in step 1 is subjected to a double-roll cold rolling process to prepare a continuously adjustable glass sheet with a thickness between 0.5 and 1 mm;

[0035] The glass flakes prepared in step 2 are subjected to controlled crystallization. The crystalli...

Embodiment 3

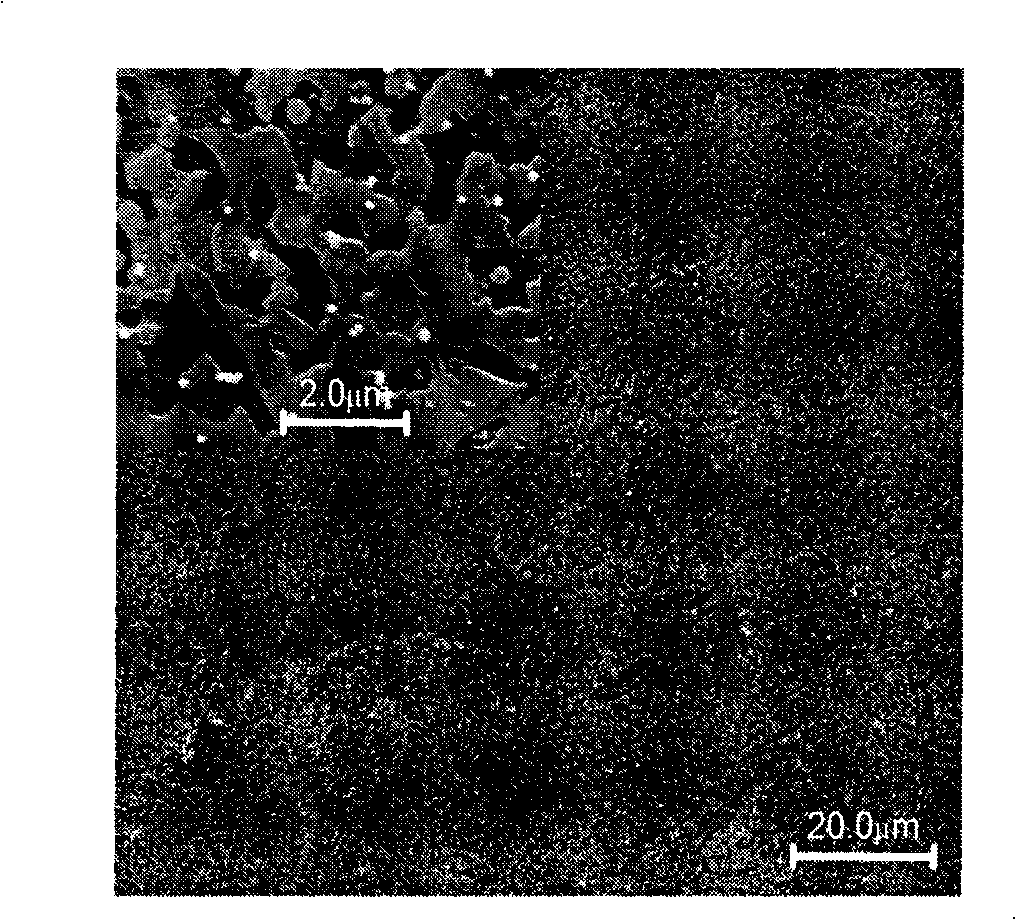

[0038] A ferroelectric glass-ceramic dielectric and its preparation method, the composition of which is Ba / Ti=1.48.

[0039] BaCO with a purity greater than 99% 3 、TiO 2 , SiO 2 , and Al 2 o 3 As the starting material, according to BaO:TiO 2 : SiO 2 :Al 2 o 3 =a: b: c: d (wherein a=0.40, b=0.27, c=0.22, d=0.11, a+b+c+d=1) molar ratio batching, the total consumption of all raw materials is 100 grams, Ba / Ti=1.48. Then these raw materials are added into a ball mill (zirconia balls and absolute ethanol, wherein absolute ethanol is the ball milling medium) in a star-shaped ball mill to grind for 4-6 hours, and after drying, they are melted at 1400-1650°C for 2-6 hours;

[0040] The high-temperature melt obtained in step 1 is cold-rolled to prepare glass flakes with a thickness between 0.5 and 1 mm that can be continuously adjusted;

[0041] The glass flakes prepared in step 2 are subjected to controlled crystallization. The crystallization process is divided into two ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com