Radiation settability composition for adhesive, polarizing film and manufacturing method thereof

A curable composition, adhesive technology, applied in the direction of adhesive types, polymer adhesive additives, non-polymer adhesive additives, etc., can solve deformation, poor heat and humidity resistance, difficult to maintain high polarization performance and other issues, to achieve excellent moisture and heat resistance, achieve the effect of moisture and heat resistance, and excellent adhesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0220] Hereinafter, the present invention will be described concretely by way of examples.

[0221] [1. Preparation of radiation-curable composition for adhesive]

[0222] Components (A) to (E) and other optional components were put into a container with a stirring device according to the compounding ratio shown in Table 1, and stirred for 4 hours to uniformly mix. Stirring was stopped, and it left still for 24 hours, and the radiation curable composition used in Example 1, 2 was obtained. The radiation curable compositions used in Reference Examples 1 and 2 were obtained in the same manner.

[0223] In addition, the compound names of each component in Table 1 are as follows.

[0224] (A) Ingredients:

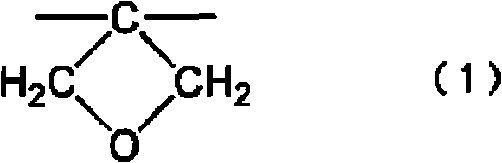

[0225] OXT-101: 3-Ethyl-3-hydroxymethyloxetane (manufactured by Toagosei Co., Ltd.)

[0226] (B) Ingredients:

[0227] JER806: bisphenol F type epoxy resin (manufactured by Japan Epoxy Resin Co., Ltd.)

[0228] JER828: bisphenol A type epoxy resin (manufactured by Japan E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com