Device for recovering copper in old electronic printed circuit board and method

A technology for electronic printing and circuit boards, which is applied in the field of recycling and utilization of copper in waste electronic printed circuit boards, and can solve the problems that metals are rarely reported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

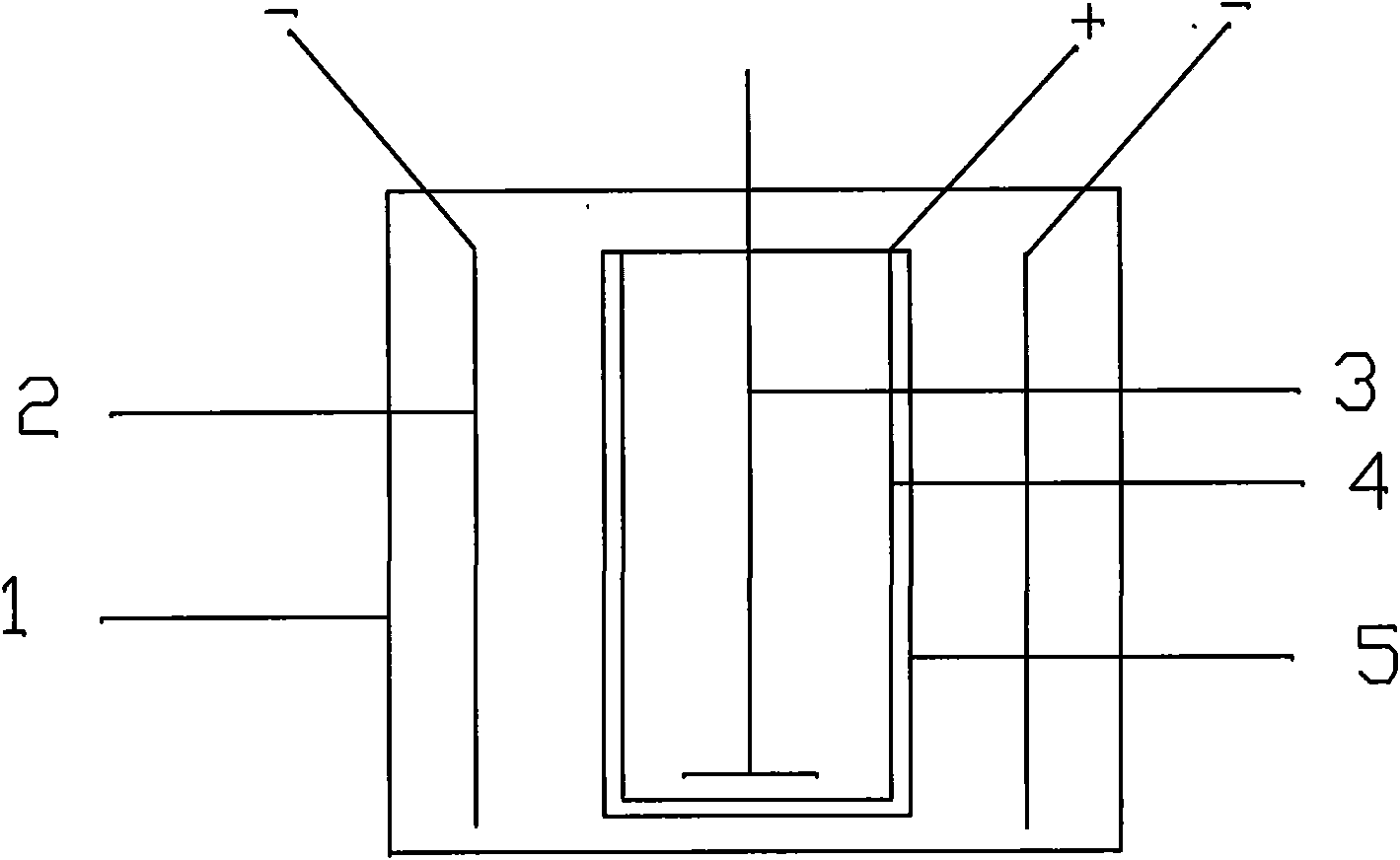

[0031] 1. The metal in the waste electronic printed circuit board is crushed into 100-mesh particles by a pulverizer, and cleaned. Dry the cleaned metal particles at 100° C. in a blast drying oven.

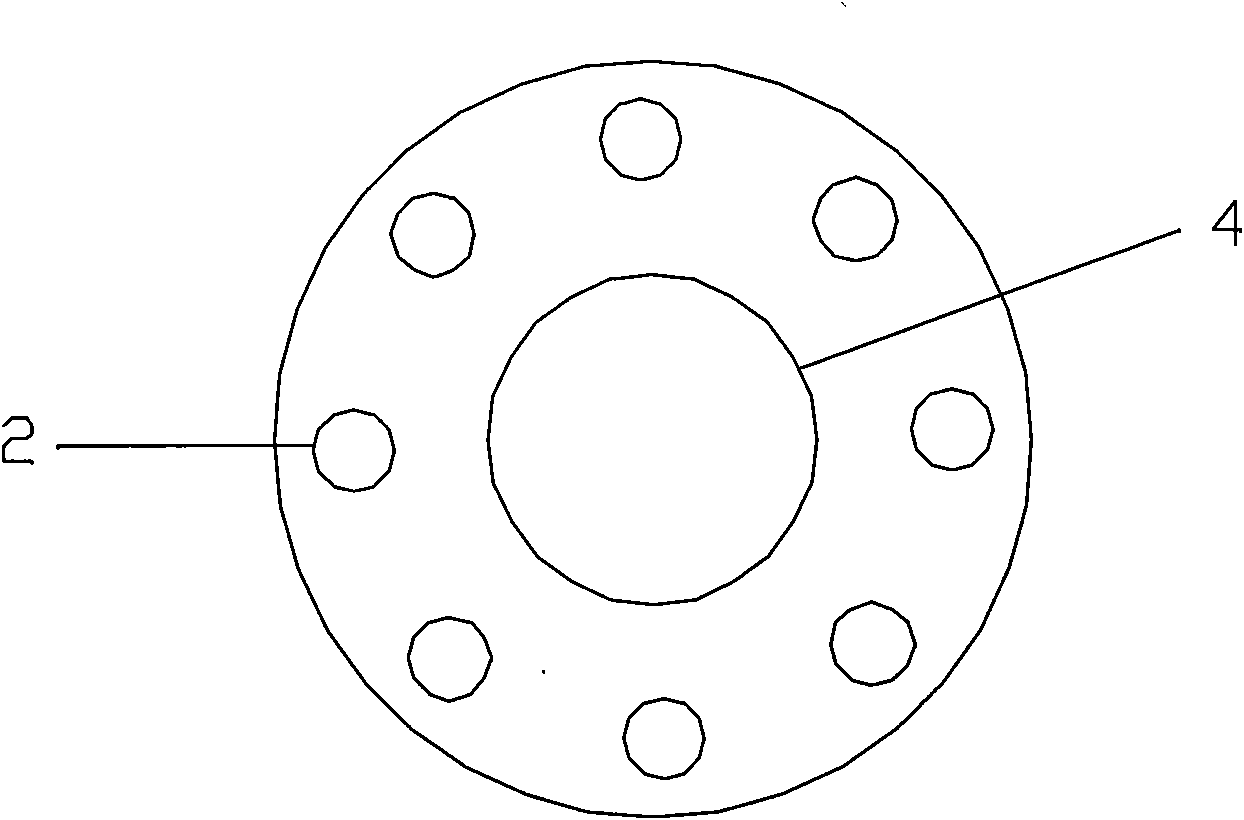

[0032] 2. The tank body is made of plexiglass, cylindrical, with a diameter of 180mm, a height of 200mm, and a pole spacing of 30mm. The cathode is a carbon rod made of 99.99% graphite, 18 mm long and 8 mm in diameter for the experiment, and 8 rods are evenly distributed in the electrolytic cell.

[0033] The titanium anode basket is 160mm high and 100mm in diameter, and the titanium anode basket is covered with 200-mesh acid-proof polyester filter cloth.

[0034] 3. Configure the raw materials according to the formula in Table 1:

[0035] The raw material ratio of table 1 example 1

[0036] Raw material Concentration

[0037] CuSO 4 (provided Cu 2+ ) 25g / L (Cu 2+ Content is 10g / L)

[0038] h 2 SO 4 100g / L

[0039] NaCl (provides Cl - ) 50mg / L (Cl...

Embodiment 2

[0045] 1. The metal in the waste electronic printed circuit board is crushed into 50-mesh particles by a pulverizer, and cleaned. Dry the cleaned metal particles at 100° C. in a blast drying oven.

[0046] 2. The tank body is made of plexiglass, cylindrical, with a diameter of 180mm, a height of 200mm, and a pole spacing of 30mm. The cathode is a steel rod made of permanent stainless steel, with a length of 18 mm and a diameter of 8 mm for the experiment, and 8 rods are evenly distributed in the electrolytic cell. The titanium anode basket is 160mm high and 100mm in diameter, and the titanium anode basket is covered with 200-mesh acid-proof polyester filter cloth.

[0047] 3. Configure the raw materials according to the formula in Table 2:

[0048] The raw material ratio of table 2 example 2

[0049] Raw material Concentration

[0050] CuSO 4 (provided Cu 2+ ) 60g / L (Cu 2+ Content is 24g / L)

[0051] h 2 SO 4 150g / L

[0052] NaCl (provides Cl ...

Embodiment 3

[0058] 1. The metal in the waste electronic printed circuit board is crushed into 20-mesh particles by a pulverizer, and cleaned. Dry the cleaned metal particles at 100° C. in a blast drying oven.

[0059] 2. The tank body is made of glass fiber reinforced plastic, cylindrical, with a diameter of 180mm, a height of 200mm, and a pole spacing of 30mm. The cathode is made of pure copper rods, 18mm in length and 8mm in diameter for the experiment, 8 of which are evenly distributed in the electrolytic cell. The titanium anode basket is 160mm high and 100mm in diameter, and the titanium anode basket is covered with 200-mesh acid-proof polyester filter cloth.

[0060] 3. Carry out the configuration of raw materials according to the formula and mass parts in the following table:

[0061] The raw material ratio of table 3 example 3

[0062] Raw material Concentration

[0063] CuSO 4 (provided Cu 2+ ) 100g / L (Cu 2+ Content is 40g / L)

[0064] h 2 SO 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com