Thin-film transistor, its manufacturing method, and display

A thin-film transistor and source technology, applied in transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problems of inability to obtain conduction current, achieve improved carrier mobility, high performance, and suppress leakage current Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

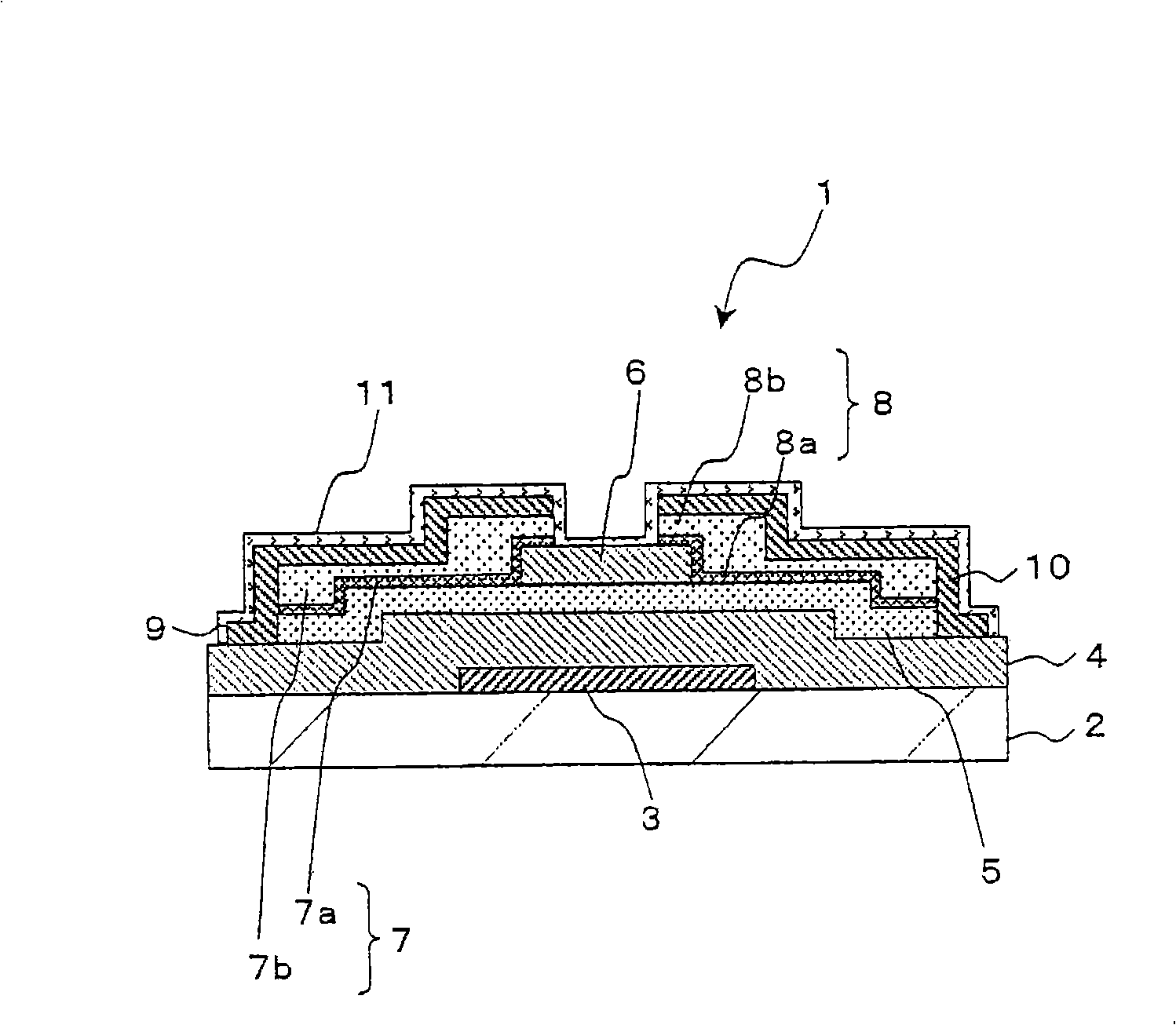

[0038] figure 1 is a cross-sectional view of the thin film transistor for explaining the first embodiment. The thin film transistor 1 shown in the figure is an n-type bottom gate thin film transistor. Strip-shaped gate electrodes 3 formed of, for example, molybdenum are pattern-formed on a substrate 2 made of an insulating substrate such as glass. The gate electrode 3 is not particularly limited, and the material may not be molybdenum as long as the material is a refractory metal that is hardly changed by heat generated when the crystallization process is performed.

[0039] A gate insulating film 4 made of, for example, a silicon oxide film is also formed to cover the gate electrode 3 . The gate insulating film 4 may be formed of a silicon nitride film, a silicon oxynitride film, or a laminated film thereof, other than a silicon oxide film.

[0040] Further, a channel layer 5 made of, for example, amorphous silicon is pattern-formed on this gate insulating film 4 in a sta...

no. 2 example

[0084] (thin film transistor)

[0085] Figure 9 is a cross-sectional view of a thin film transistor for explaining the second embodiment. The thin film transistor 1' shown in this figure is a top gate type thin film transistor, and a source layer 7 and a drain layer 8 are provided by being laminated on a source electrode 9 and a drain electrode 10 patterned on a substrate 2 . Furthermore, as a characteristic structure in the present invention, source / drain layers 7 and 8 contain impurities with a concentration gradient such that the concentration becomes lower toward channel layer 5 . Specifically, the source layer 7 has a two-layer structure consisting of the second silicon layer 7b covering the source electrode 9 and the first silicon layer 7a on the second silicon layer, and the drain layer 8 has a silicon layer covering the drain electrode 10. A two-layer structure composed of the second silicon layer 8b and the first silicon layer 8a on the second silicon layer. Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com