Vegetable proteins extracted from P.octandra, preparation method and application thereof

A technology of plant protein and extraction method, which is applied in the field of pharmaceuticals, can solve the problems of no treatment method, etc., and achieve the effect of definite curative effect and clear ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

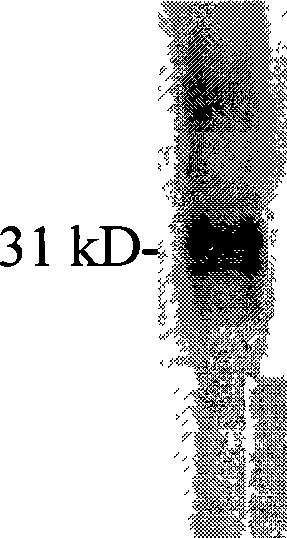

Image

Examples

Embodiment 1

[0036] Embodiment 1: Extract crude vegetable protein, fine protein and protamine from ink grass (P.octandra)

[0037] 1). Homogenate: Collect and weigh 1 kg of the spring leaves of Mocao, add 2 liters of 10mM phosphate buffer pH6.5, mash it with T50 Basic ULTRA-TURRAX to form a homogenate, filter and keep the filtrate for later use.

[0038] 2). Ammonium sulfate two-step precipitation: a). Take 1.95 liters of the filtrate obtained in step 1) and add 1.05 liters of ammonium sulfate saturated solution slowly and uniformly in proportion to make it 35% ammonium sulfate saturation; stand at 10°C for 1 Hour. Centrifuge precipitation (20°C, 30 minutes, 3000g centrifugal force) to retain the supernatant; b). Add solid ammonium sulfate to the obtained supernatant under stirring to make it 100% ammonium sulfate saturation, and continue stirring at 20°C for 15 hours. Precipitate by centrifugation (20°C, 30 minutes, 3000g centrifugal force), carefully discard the supernatant and retain t...

Embodiment 2

[0049] Embodiment 2: Extract crude vegetable protein, fine protein and protamine from ink grass (P.octandra)

[0050] 1). Homogenate: Collect and weigh 1 kg of the spring leaves of Mocao, add 2 liters of 8mM phosphate buffer pH5, mash with T50Basic ULTRA-TURRAX to form a homogenate, filter and keep the filtrate for later use.

[0051] 2). Ammonium sulfate two-step precipitation: a). Take 1.95 liters of the filtrate obtained in step 1) and slowly add saturated ammonium sulfate solution in proportion to the saturated ammonium sulfate solution at a constant speed in a stirring state to make the saturation of ammonium sulfate 30%; stand at 4°C for 0.5 hours. Centrifuge precipitation (4°C, 30 minutes, 3000g centrifugal force) to retain the supernatant; b). Add solid ammonium sulfate to the obtained supernatant under stirring to make it 100% ammonium sulfate saturation, and continue stirring at 4°C for 2 hours. Precipitate by centrifugation (4°C, 30 minutes, 3000g centrifugal force)...

Embodiment 3

[0062] Embodiment 3: Extract crude vegetable protein, fine protein and protamine from Chinese ink grass (P.octandra)

[0063] 1). Homogenate: Collect and weigh 1 kg of the spring leaves of Mocao, add 2 liters of 12mM phosphate buffer pH8, mash it with T50Basic ULTRA-TURRAX to form a homogenate, filter and keep the filtrate for later use.

[0064] 2). Ammonium sulfate two-step precipitation: a). Take 1.95 liters of the filtrate obtained in step 1) and add the saturated ammonium sulfate solution slowly and uniformly in proportion to 40% ammonium sulfate saturation under stirring state; stand at 20°C for 2 hours. Centrifuge precipitation (20°C, 30 minutes, 3000g centrifugal force) to retain the supernatant; b). Add solid ammonium sulfate to the obtained supernatant under stirring to make it 100% ammonium sulfate saturation, and continue stirring at 20°C for 18 hours. Precipitate by centrifugation (20°C, 30 minutes, 3000g centrifugal force), carefully discard the supernatant and r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com