Purification method applicable to manufacturing food-grade ovalbumin on large scale

A large-scale preparation, ovalbumin technology, applied in the preparation method of peptides, ovalbumin, albumin peptides and other directions, can solve the problems of limited separation scale, high salt content, need expensive equipment, etc., to achieve clear product composition, The effect of a wide range of sources and easy large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

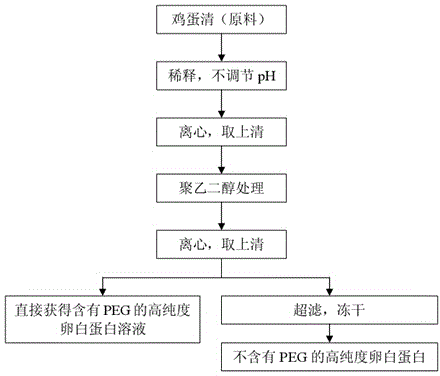

Image

Examples

Embodiment 1

[0026] Take 100ml of fresh egg whites for two parts, add 200ml of fresh deionized water respectively, without adjusting the pH, stir evenly for 1 hour, and centrifuge at 8000 rpm for 30min to remove the precipitate.

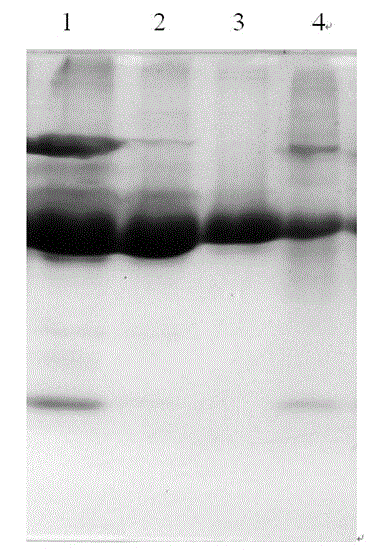

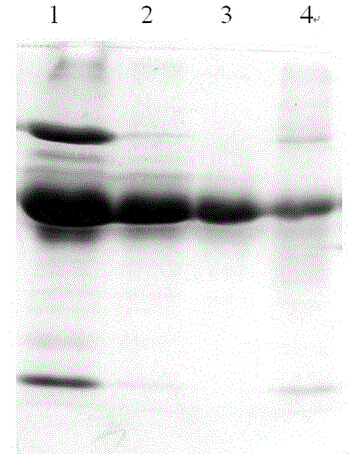

[0027] To the supernatant obtained by the first centrifugation, add polyethylene glycol 200 to its mass percentage concentration of 15%, stir for 1 hour, centrifuge at 8000rpm for 30min, collect the supernatant, which is the polyethylene glycol-containing high Purity ovalbumin solution. The solution is ultrafiltered with an ultrafiltration membrane with a membrane molecular weight cut-off of 30 kDa, and the cut-off part is subjected to vacuum freeze-drying to obtain a white powder, which is high-purity ovalbumin without polyethylene glycol. The obtained ovalbumin was detected by sodium dodecylsulfonate-polyacrylamide gel electrophoresis, which showed that the ovalbumin content accounted for 82.9% of the total protein content, and the purity was higher than that o...

Embodiment 2

[0031] Take 100ml of fresh egg whites for two parts, add 200ml of fresh deionized water respectively, without adjusting the pH, stir evenly for 1 hour, and centrifuge at 8000 rpm for 30min to remove the precipitate.

[0032] Add polyethylene glycol 20,000 to the supernatant obtained by the first centrifugation until its mass percentage concentration is 15%, stir for 1 hour, centrifuge at 8000rpm for 30min, and collect the supernatant, which is the polyethylene glycol-containing high Purity ovalbumin solution. The solution is ultrafiltered with an ultrafiltration membrane with a membrane molecular weight cut-off of 30 kDa, and the cut-off part is subjected to vacuum freeze-drying to obtain a white powder, which is high-purity ovalbumin without polyethylene glycol. The obtained ovalbumin was detected by sodium dodecylsulfonate-polyacrylamide gel electrophoresis, which showed that the content of ovalbumin accounted for 86.2% of the total protein content, and the purity was higher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com