On-line monitoring oil-gas separation device for transformer

A separation device, oil and gas separation chamber technology, applied in transformer/inductor cooling, separation method, liquid degassing, etc., can solve the problems of difficult separation, deterioration, pollution, etc., achieve high degassing efficiency, convenient installation, and overcome pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

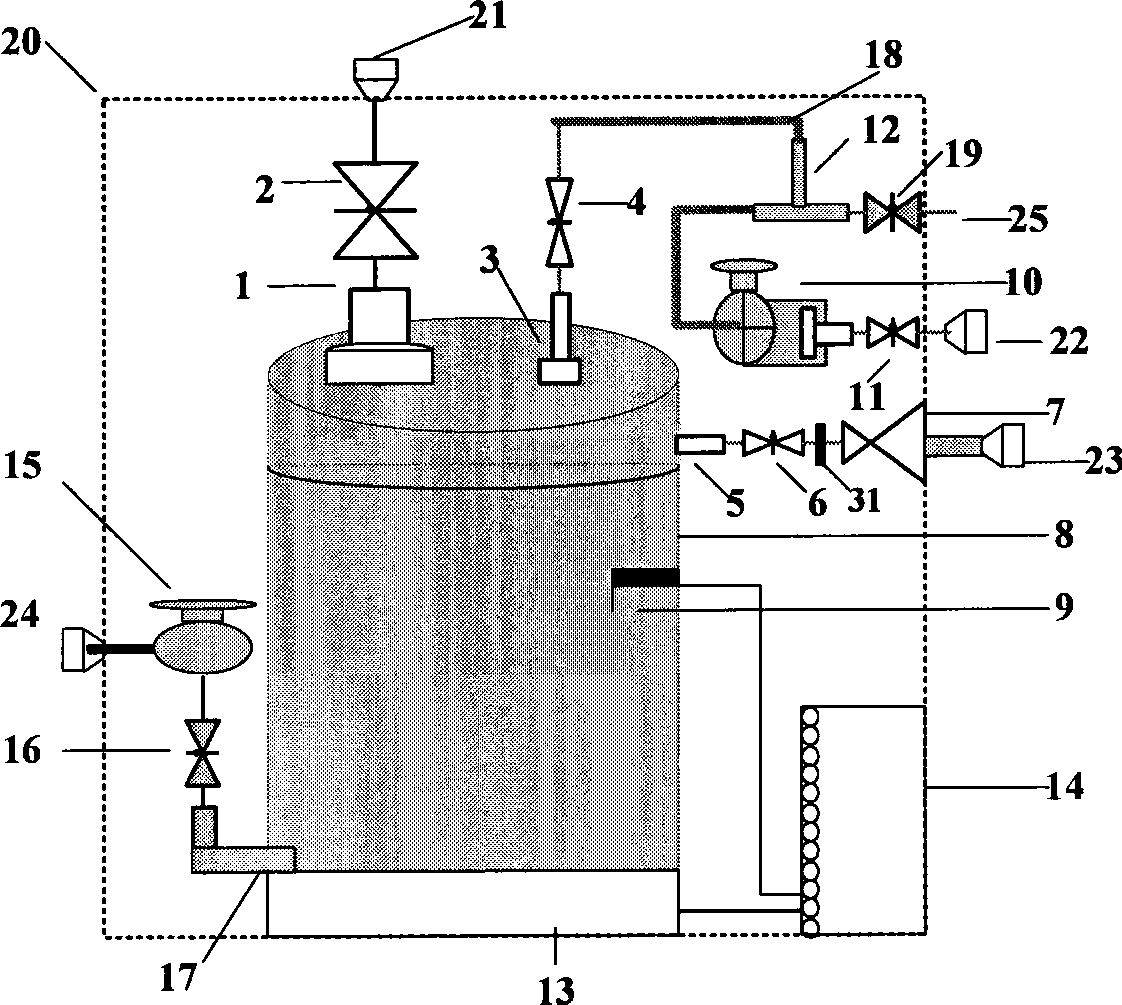

[0019] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

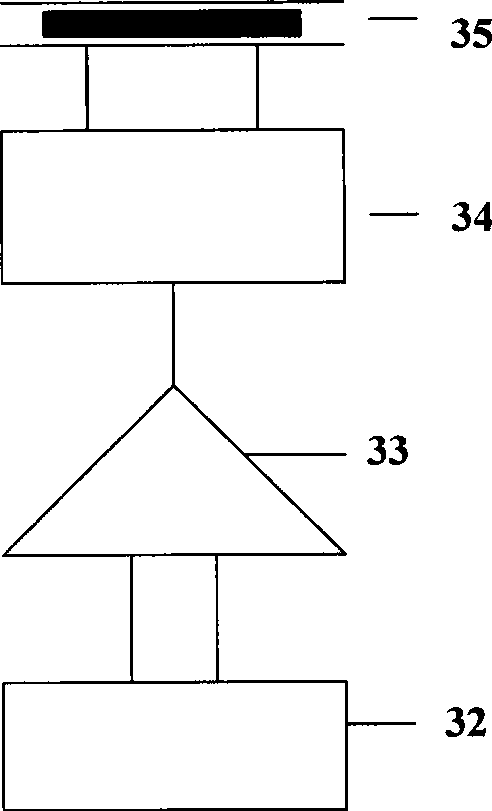

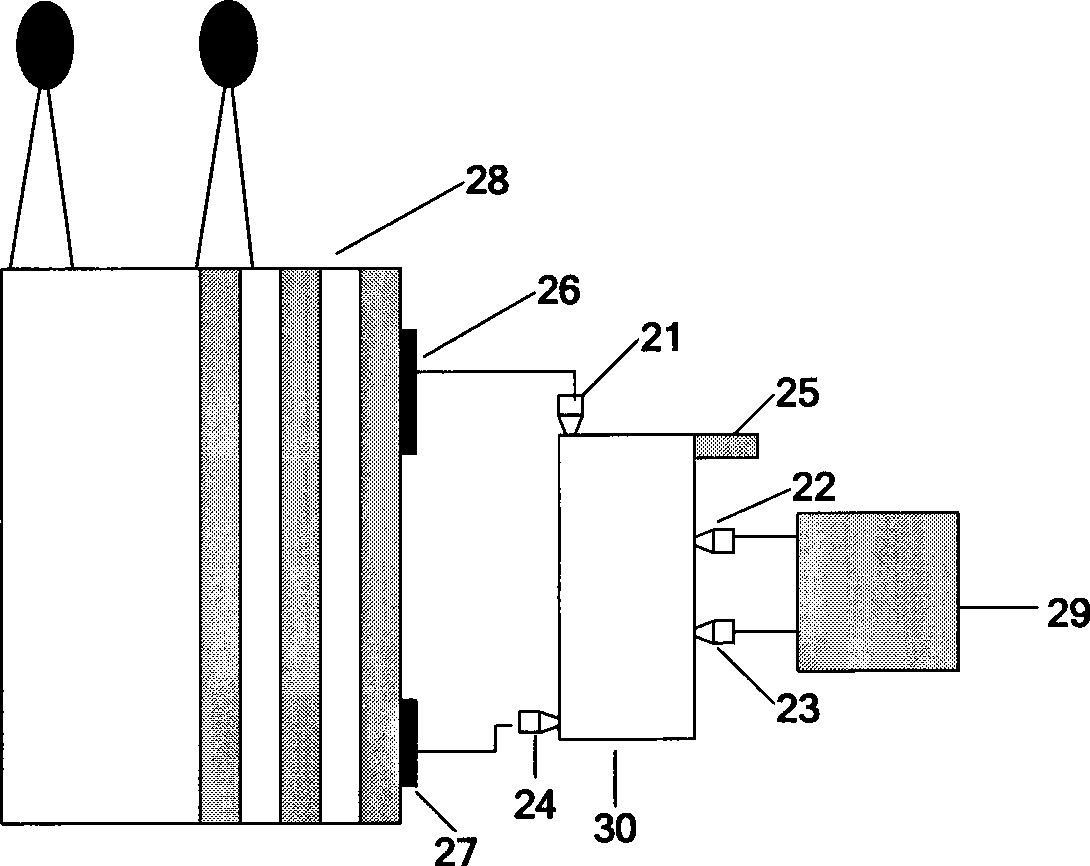

[0020] Such as figure 1 As shown, this embodiment includes: an oil inlet 1, a solenoid valve 2, an air inlet 3, a solenoid valve 4, an air outlet 5, a solenoid valve 6, a flow limiting valve 7, an oil-gas separation chamber 8, a liquid level detector 9, Vacuum pump 10, electromagnetic valve 11, T-shaped pipe 12, ultrasonic oscillator 13, PLC control module 14, oil return pump 15, electromagnetic valve 16, oil return port 17, polytetrafluoroethylene tube 18, electromagnetic valve 19, shielding box 20, Oil inlet valve external terminal 21, vacuum pump external terminal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com